烤煙煙夾烘烤過程中葉間隙風(fēng)速的研究

張保全+陳小翔+馬留軍+崔慶偉+鄭登峰+曹廷茂+代昌明+蔣明貴+劉瓊

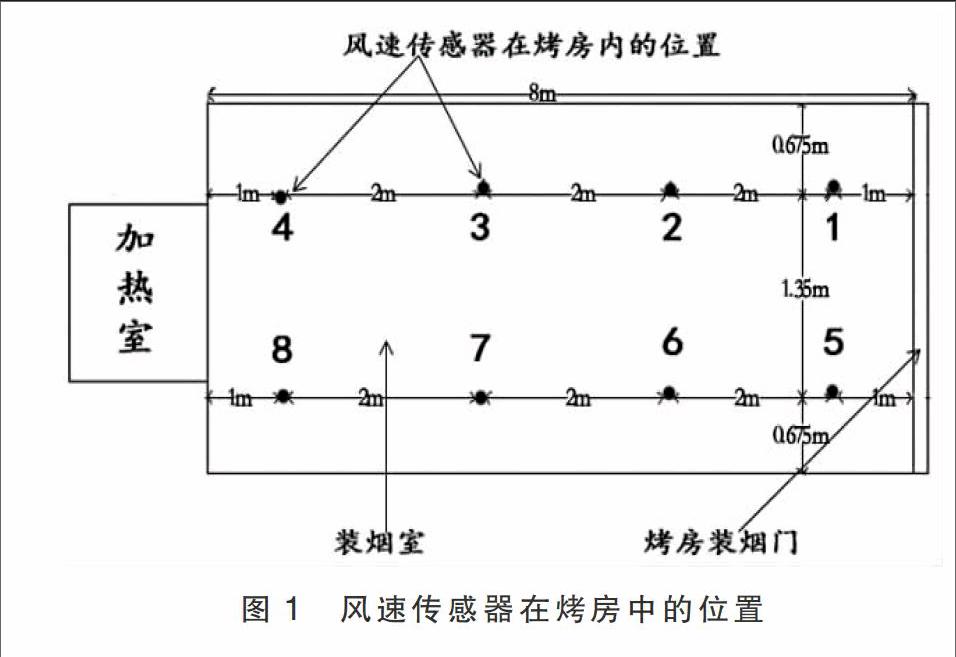

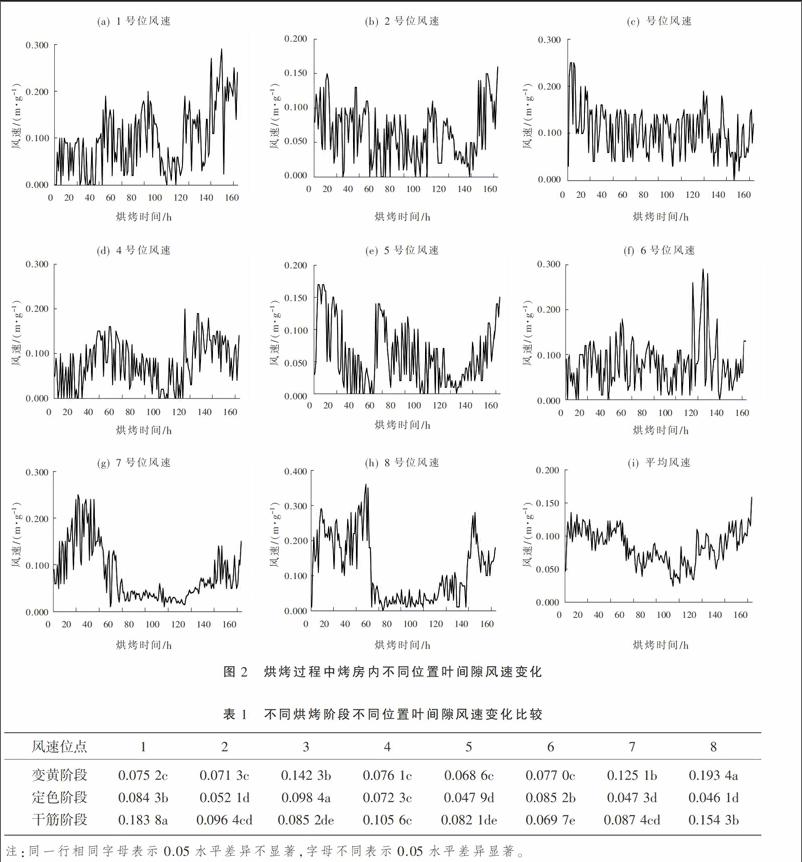

摘 要:為了解散葉烘烤過程中煙葉不同位點(diǎn)的葉間隙風(fēng)速的變化以及影響風(fēng)速變化的主要因素,利用風(fēng)速儀對中棚煙葉距離加熱室1,3,5,7 m處的8個(gè)位點(diǎn)的葉間隙風(fēng)速進(jìn)行實(shí)時(shí)監(jiān)測,同時(shí)記錄烤房的干濕球溫度,并于烘烤開始后每隔4 h取1次樣,測定葉片與葉脈的含水率。結(jié)果表明:烘烤過程中8個(gè)位點(diǎn)葉間隙風(fēng)速差異較大,其中6號位點(diǎn)的風(fēng)速始終處于較低水平;不同烘烤階段各位點(diǎn)風(fēng)速的變化大體表現(xiàn)為先降后升的趨勢;濕球溫度在整個(gè)烘烤過程中對葉間隙風(fēng)速的影響最大,直接通徑系數(shù)為-0.974 9,葉片含水率對葉間隙風(fēng)速也有較大影響,直接通徑系數(shù)為0.404 4。在烘烤中可以通過控制煙葉含水率與濕球溫度等來調(diào)控葉間隙風(fēng)速的變化,并進(jìn)一步改善煙葉質(zhì)量。

關(guān)鍵詞:散葉烘烤;葉間隙風(fēng)速;烘烤階段;通徑分析

中圖分類號:S573 文獻(xiàn)標(biāo)識碼A DOI 編碼:10.3969/j.issn.1006-6500.2017.07.023

Research on Wind Speed of Leaves Gap in Tobacco-clamp Curing Process

ZHANG Baoquan1, CHEN Xiaoxiang1, MA Liujun1, CUI Qingwei2, ZHENG Dengfeng2, CAO Tingmao2, DAI Changming2, JIANG Minggui2, LIU Qiong2

(1. China Tobacco Zhejiang Industrial Limited Company,Hangzhou, Zhejiang 310004, China; 2. Bijie Tobacco Company of Guizhou Province, Bijie, Guizhou 551700, China)

Abstract: In order to study the changes of wind speed of tobacco leaves gap in curing process and the main factors that affect the wind speed change, in middle layer the leaves gap wind of 8 loci, which were from the heating chamber 1, 3, 5, 7 m, were real time monitored using anemometer in lose-leaf curing process, and the wet bulb temperature and dry bulb temperature were recorded in curing process. Then the samples were taken each 4 h since beginning, and the water content of leaf blade and main veins were determined. The results showed that there was a quite difference of leaves gap wind among the 8 loci in curing process, of which the wind speed of 6 th loci was always at a low level, the change of wind speed ever loci was more complex in different curing stage, however, the tendency of most loci was ascend first and then descend. And the wet bulb temperature had the greatest influence on leaf gap wind speed in the curing process, the direct path coefficient was -0.974 9, the leaf water content also had a greater influence on leaf gap wind speed, the direct path coefficients was 0.404 4. In the curing process, the leaf gap wind speed could be controlled by controlling the moisture content of the leaves and the wet bulb temperature, and this can be used to improve the quality of tobacco leaves.

Key words: lose-leaf curing; wind speed of leaf gap; curing stage; path analysis

煙葉密集烘烤利用循環(huán)風(fēng)機(jī)使熱空氣在烤房內(nèi)不斷流動,進(jìn)而控制煙葉的變黃與失水[1-3]。烘烤過程中熱風(fēng)將煙葉內(nèi)部排出的水分帶走,風(fēng)速越大煙葉水分被帶走的效率就越高[4]。烘烤過程中葉間隙風(fēng)速的大小對煙葉外觀質(zhì)量與感官質(zhì)量以及化學(xué)成分的形成有著重要影響[5-8]。宮長榮等[9]研究表明,烘烤過程中葉層間風(fēng)速在變黃階段、定色階段與干筋階段為0.22±0.05,0.35±0.12,0.40±0.17 m·s-1時(shí)烤后煙外觀質(zhì)量較好。詹軍等[7-8]研究表明,適當(dāng)降低干筋期風(fēng)機(jī)轉(zhuǎn)速能明顯改善煙葉的香氣質(zhì)量,且干筋前期降低風(fēng)機(jī)轉(zhuǎn)速對香氣物質(zhì)含量的影響相對于后期更大。……