銑削顫振過程非線性振動特性的在線分析

吳石 王洋洋 劉獻禮 許紅 李榮義

摘要:為了分析銑削顫振過程的非線性動力學行為特性,首先基于工件振動信號的相位差、最大李雅譜諾夫指數、排列熵等,分析變切深銑削過程中平穩銑削振動信號、顫振孕育振動信號和顫振振動信號的的非線性特征。然后基于虛擬儀器平臺開發了銑削振動信號的采集與分析系統,進行在線預報銑削顫振實驗。試驗結果表明,振動信號的相位特征可以有效檢測銑削顫振,但不能有效預報切削顫振孕育;在銑削顫振不同階段,振動信號的李雅譜諾夫指數的敏感程度不同,排列熵的閾值也不同。這樣,相位差特征和混沌特征可以同時作為識別顫振孕育、發生的有效手段。

關鍵詞:銑削顫振;虛擬儀器;最大李雅譜諾夫指數;相位差;排列熵

DOI:10.15938/j.jhust.2018.01.001

中圖分類號: TH164;TG501

文獻標志碼: A

文章編號: 1007-2683(2018)01-0001-06

Abstract:In order to analyze the nonlinear dynamic behavior of the milling chatter, firstly to analyze the varying depths of cut during milling stationary vibration signal the vibration signal and bred flutter vibration signal nonlinear characteristics based on the phase difference and the maximum Lyapunov exponent permutation entropy ect of the vibration signal of the workpiece. Then to develop the milling vibration signal acquisition and analysis system for online forecasting milling chatter experiment based on virtual instrument platform. The experimental results showed that, the phase of vibration signal characteristics can effectively detect the milling chatter. But that can't be effective prediction of cutting chatter. At the different stages of cutting chatter, the sensitivity of the Lyapunov exponent of the vibration signal is different. The threshold of permutation entropy is also different. The characteristics of phase difference and chaotic characteristics can be used as an effective method for the identification of chatter.

Keywords:milling chatter; virtual instrument; maximum Lyapunov exponent; phase difference; permutation entropy

0引言

切削顫振是機械加工過程中十分有害的振動現象,它不僅會使生產率和加工精度下降,還會使刀具破損,甚至會影響機床的加工精度,因此針對切削信號進行在線監測與顫振控制一直是研究的熱點問題[1-2]。隨著科技的進步與測試的需求,基于虛擬儀器(Labview)的數據采集與測試系統受到了廣大學者的好評,目前虛擬儀器技術已經成為切削振動在線監測的一個重要研究內容[3-4]。

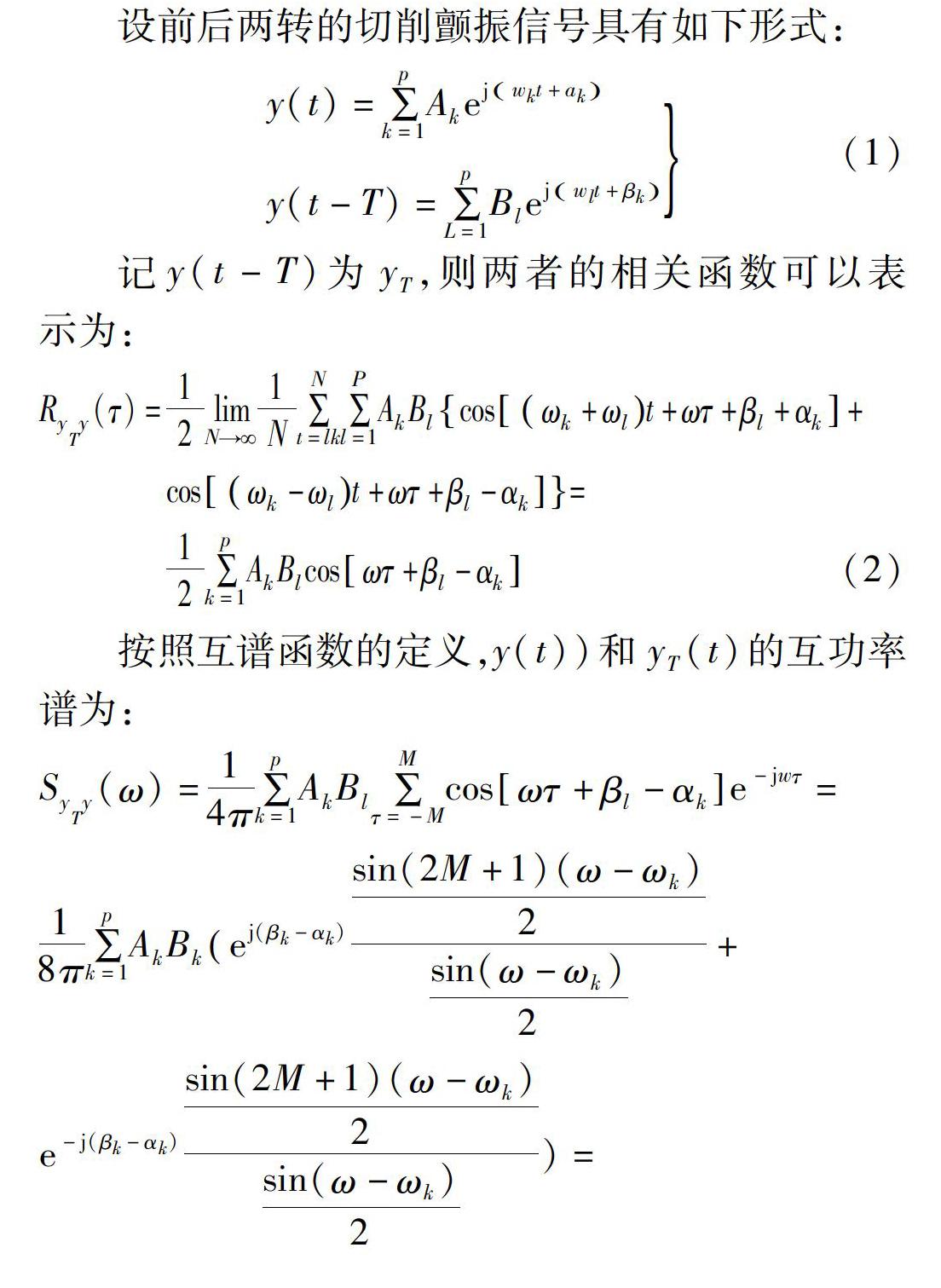

在實際加工中主軸—刀具—工件、以及夾具系統是復雜的非線性系統,切削振動信號屬于非線性信號[5],特別是發生銑削顫振時,非線性現象尤其突……