輕合金擠壓成形/成性一體化的研究進展

王野 李峰 王宇 王雁鵬

摘 要:為了充分發揮擠壓工藝在高性能輕合金制備和成形兩個層面上的技術特點與集成優勢,輕合金擠壓成形/成性一體化應運而生并逐漸成為本領域的研究熱點問題之一。該類方法的技術特點在于通過對擠壓模的優化設計、加載形式及坯料結構等的改變,將以往獨立的細晶制備工序巧妙融入到擠壓過程中,在單道次內即達到了對擠出制品“形/性”雙控的實效。從研究概況的“縮影”可以看出,與常規擠壓相比,在降低成形載荷、改善擠出流動均勻性、提高制品組織性能等諸多方面都體現出了其綜合優勢。隨著相關基礎科學問題的解決,藉此為高性能輕合金短流程控形及控性一體化技術的研究和應用提供科學指導。

關鍵詞:輕合金;擠壓;控形;控性;組織

DOI:10.15938/j.jhust.2019.05.001

中圖分類號: TG376

文獻標志碼: A

文章編號: 1007-2683(2019)05-0001-06

Abstract:Extrusion processes can exert technical characteristics and integration advantages in preparing and forming lightweight high-performance magnesium alloys. The lightweight alloy extrusion integration consisting of forming and modification emerged as the times require, and has gradually become one of the hot topics in extrusion field. The technical characteristics of above processes are that the previous independent fine grain preparation processes is skillfully integrated into the extrusion processes through optimizing extrusion dies, changing loading modes and adjusting the structure of billets, etc. The actual effects of “shapes/properties” dual control of extrusion products have been achieved in a single pass. It can be seen from the microcosm of the research overviews that compared with the conventional extrusion, its comprehensive advantages are reflected in many aspects such as reducing forming load, improving the uniformity of extrusion flow, and improving the microstructure properties of the extruded products. To solve the related basic scientific problems, it provides scientific guidance for the research and application of lightweight high-performance alloy in short process and dual control of shape/performance.

Keywords:light alloys; extrusion; shape control; performance control; microstructure

0 引 言

鋁鎂合金兼具多種優異的綜合性能,是航空航天、軌道交通、武器裝備等領域實現輕量化的理想首選,具有廣闊的發展潛力及應用前景[1-3]。傳統輕合金構件成形多采用鑄造工藝,但鑄件材質不夠致密、承載能力及制品性能存在不足之處。比較而言,塑性加工法更利于輕合金構件組織和力學性能的改善。以擠壓工藝為例,成形過程中變形區內因具有三向受壓應力狀態和可提供較大的剪切變形量而使被加工制品獲得細晶組織及優異的力學性能[4-6],因此,該工藝逐漸成為鋁鎂等輕質合金構件主要的加工成形手段[7-9]。

我國鋁鎂資源儲備非常豐富,但深加工技術的開發能力和高附加值制品的產出等方面與國外發達國家仍存在著明顯差距,是長期困擾傳統輕合金擠壓技術快速發展及拓展應用的癥結所在,更是輕合金高效精確塑性成形前沿研究領域所關注的關鍵基礎科學問題之一[10]。

當前圍繞輕合金擠壓成形的相關研究工作主要集中在改性和成形兩個不同層面上。前者是利用擠壓工藝提供的剪切變形作為細晶改性手段來實施的[11-12],后者則是針對半成品或成品加工成形的技術手段[13]。發展擠壓成形/成性一體化技術是促進輕合金短流程深加工潛能提升的重要途徑。

1 結構設計

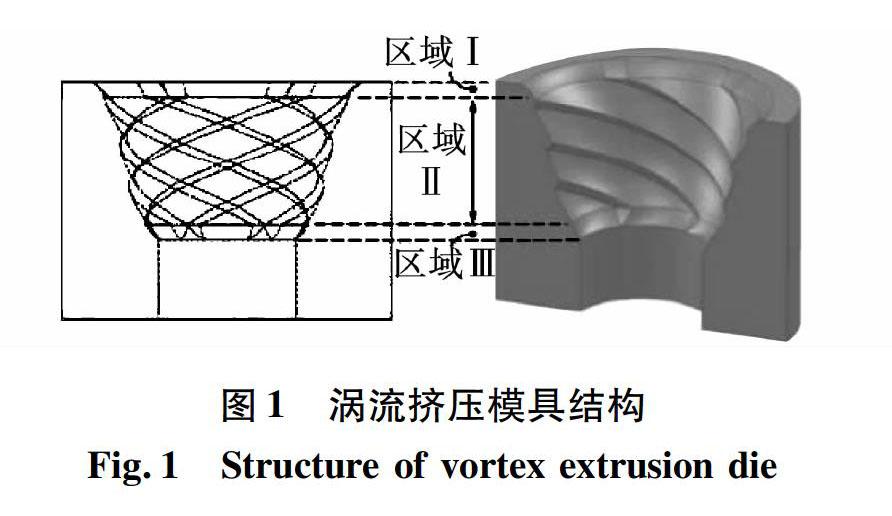

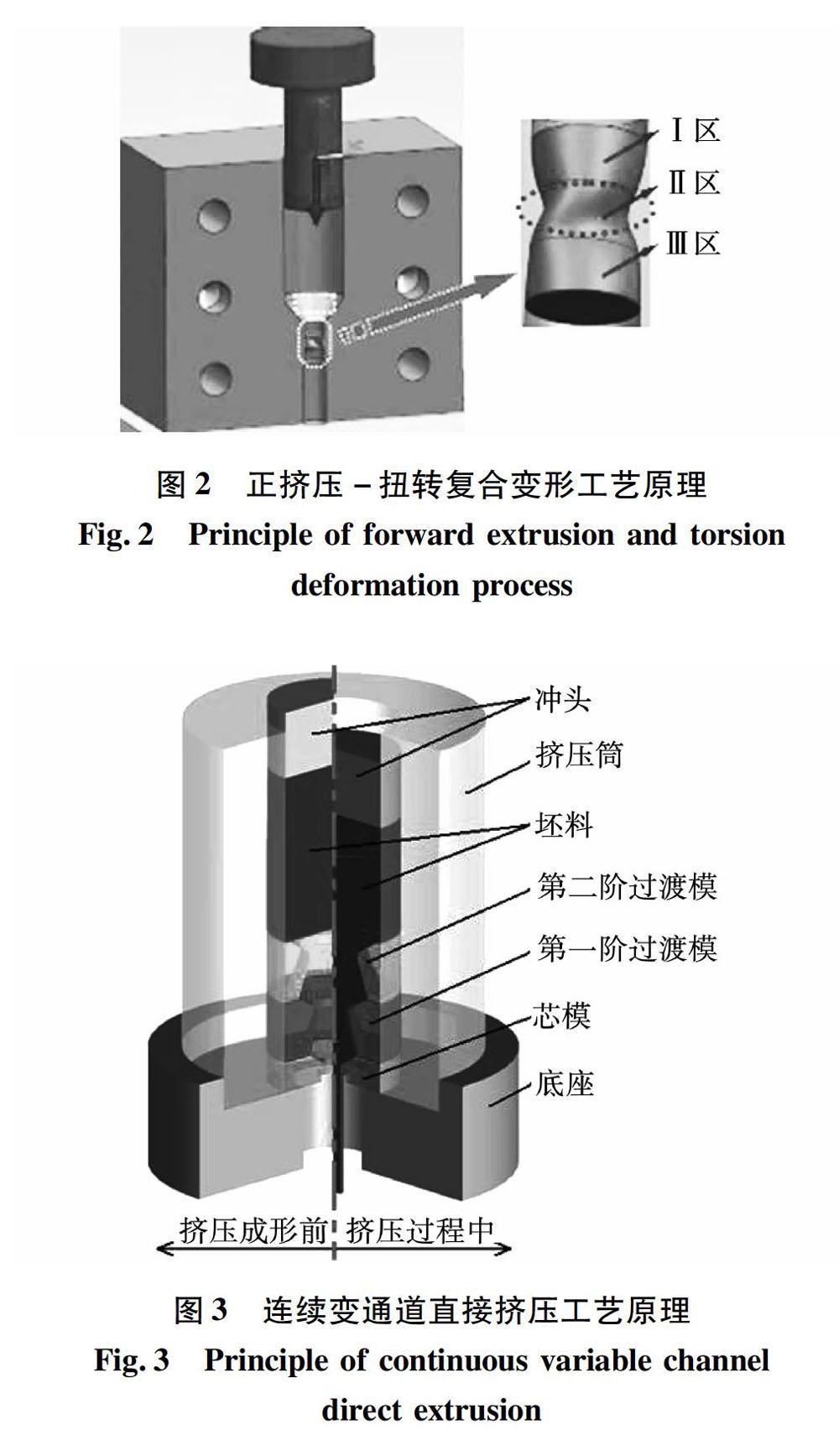

1.1 模具結構

模具結構是決定擠出流動行為、制品組織及力學性能的重要因素之一,因此,模腔結構的精準設計顯得尤為關鍵。XU等[14]對不同模角擠壓成形制品進行了對比研究,結果表明,芯模半角為45°時獲得AZ31鎂合金板材內部組織較均勻,具有較弱的基面織構,屈服強度較低,但延展性較好,相對來講,其綜合性能仍為最佳。

圖5 鎂合金轉模擠壓的晶粒尺寸對比

Fig.5 The comparison of grain size for magnesium alloy

by extrusion through rotating container

此外,YU等[42]對反擠壓凹模施加了旋轉嘗試,對擠壓成形管狀制品微觀組織及性能的研究結果表明:轉速與顯微硬度呈反比趨勢變化;當溫度和應變速率不變時,晶粒尺寸隨轉速的增加而變大,而動態再結晶細化和晶粒生長呈動態競爭關系。

2.3 側向加載

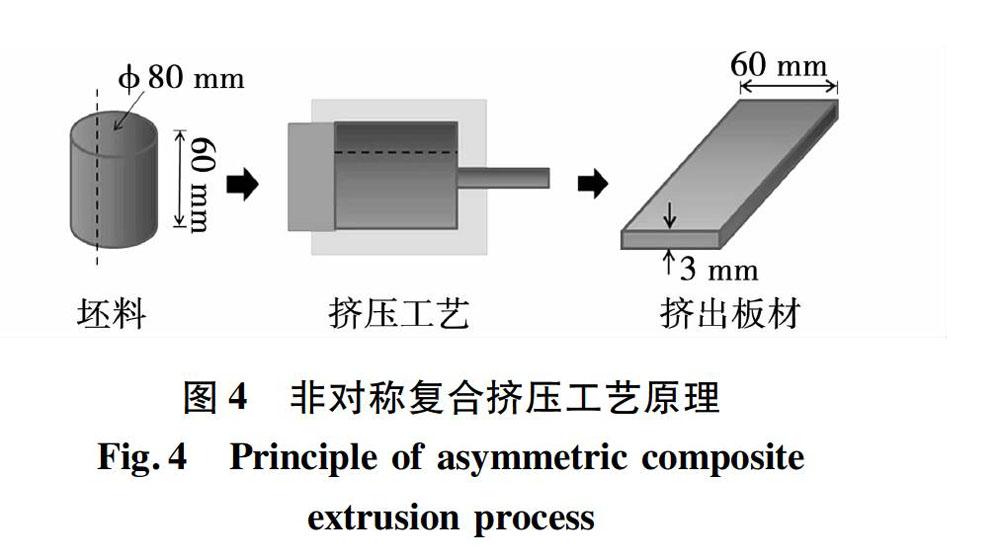

芯模是決定擠出制品形狀的關鍵結構,研究者們突破了傳統的芯模設計理念,將其設計成可動式結構,隨著擠壓過程的進行,可獲得截面連續變化的擠出制品。

LIN等[43]設計了一種可以實現側向柔性加載的變截面擠壓成形工藝,即通過分別調控固定模和活動模獲得沿長度方向具有變化截面的棒材或管材,原理如圖6所示,擠壓過程中關鍵是準確動態地調整所圍成形模孔的幾何形狀及尺寸。同時基于等效體積理論,提出了一種新的動模調控模型,并給出了該模型的數值計算方法和程序結果表明,該運動控制模型具有足夠的精度和精度,可用于設計及參數計算。

胡水平等[44]開發出了一種與電、液、計算機技術融為一體的連續變斷面擠壓法,原理如圖7所示。以工業純鋁為研究對象,通過調節主液壓缸和側向伺服液壓系統的參數,可以獲得截面尺寸呈連續規律變化的擠出構件。無須在擠壓過程中停機更換模具,使生產效率大幅度提高。隨后對連續變斷面擠壓工藝進行了實驗,研究結果表明[45]:沿長度方向上制品組織很不均勻,晶粒尺寸由試樣外層到中部逐漸變大,需通過后續熱處理進行調控。

2.4 交替加載

對擠壓凸模進行離散設計并交互下載作用也能達到節省載荷和細化晶粒的效果。基于這種思想,LI等[46]提出了交替擠壓法,原理如圖8所示。該工藝采用分體式凸模代替整體式結構,交替向下施加載荷。以兩半分體凸模結構為例,加載模式可分為遞進式和交互式。

LIU等[47]將常規擠壓法與交替擠壓法進行了對比研究,結果表明,交替擠壓過程中除擠壓模口周圍外,交替下行加載過程中不同分體沖頭之間交界面處可產生了持續劇烈的附加剪切變形作用,促進了低塑性鎂合金內部組織的深度細化,利于擠出制品綜合力學性能的改善及質量的提高。

3 結論及展望

1)輕合金擠壓成形/成性一體化是高效精確塑性成形前沿研究領域所關注的重要基礎科學問題之一。為解決本領域長期存在的生產效率低、形狀尺寸精度和組織性能協同控制難度大等難題提供了一種新思路;

2)輕合金擠壓成形/成性一體化雖具有一定的改性優勢,但與大塑性變形技術有著本質區別,不能混淆。如不具備重復多次加載、獲得超細晶組織等技術特征,與大塑性變形技術相比,更易于在生產實際中推廣應用;

3)高效低耗地進行制品形狀和性能的短流程精確調控是改善輕合金擠壓件綜合質量、提高生產效率及擴大適用范圍的根本“良方”之一。隨著使用需求的日益增高,輕合金擠壓成形/成性一體化的“奇思妙想”仍在不斷涌現并與時俱進地發展。

參 考 文 獻:

[1] 丁文江, 吳玉娟, 彭立明. 高性能鎂合金研究及應用的新進展[J]. 中國材料進展, 2010, 29(8):37.

[2] 王凱鋒, 馮義成, 張靖, 等. 等溫處理對Mg-3Al-2Ca- 2Nd組織和性能的影響[J]. 哈爾濱理工大學學報, 2018,23(1):35.

[3] 馮義成,王琴,楊建輝,等. Ca 對 Mg-6Al-1Nd 合金顯微組織 和性能的影響[J]. 哈爾濱理工大學學報, 2014, 19(5):10.

[4] HSIANG SU-HAI, LIN YI-WEI, LAI JHONG-WEI. Optimization of Hot Extrusion Process for AZ61 Magnesium Alloy Carriers[J]. International Journal of Material Forming, 2012,5(3):259.

[5] YU Z J, HUANG Y D, QIU X, et al. Fabrication of Magnesium Alloy with High Strength and Heat-resistance by Hot Extrusionand Ageing[J]. Materials Science and Engineering: A, 2013,578:346.

[6] 陳增奎, 蔣清, 周衛衛, 等. AZ31鎂合金薄壁管材擠壓技術研究[J]. 精密成形工程, 2016(3):34.

[7] 董媛媛, 張存生, 趙國群, 等. 7×××系空心鋁型材擠壓橫向焊縫的研究[J]. 精密成形工程, 2017,9(5):98.

[8] LI N, HUANG G, XIN R, et al. Effect of Initial Texture on Dynamic Recrystallization and Deformation Mechanisms in AZ31 Mg Alloy Extruded at 573K[J]. Materials Science and Engineering: A, 2013, 569:18.

[9] 李落星, 周佳, 張輝. 車身用鋁、鎂合金先進擠壓成形技術及應用[J]. 機械工程學報, 2012, 48(18):35.

[10]楊合, 李落星, 王渠東, 等. 輕合金成形領域科學技術發展研究[J]. 機械工程學報, 2010, 46(12): 31.

[11]CHEN Y J, WANG Q D, ROVEN H J, et al. Microstructure Evolution in Magnesium Alloy AZ31 During Cyclic Extrusion Compression[J]. Journal of Alloys and Compounds, 2008,462(1/2):192.

[12]STRSK JITKA, JANEEK MILO, EK JAKUB, et al. Microstructure Stability of Ultra-Fine Grained Magnesium Alloy AZ31 Processed by Extrusion and Equal-Channel Angular Pressing (EX-ECAP)[J]. Materials Characterization, 2014, 94:69.

[13]LI L, ZHANG H, ZHOU J, et al. Numerical and Experimental Study on the Extrusion Through a Porthole Die to Produce a Hollow Magnesium Profile with Longitudinal Weld Seams[J]. Materials and Design, 2008,29:1190.

[14]XU J, YANG T H, JIANG B, et al. Improved Mechanical Properties of Mg-3Al-1Zn Alloy Sheets by Optimizing the Extrusion Die Angles: Microstructural and Texture Evolution [J]. Journal of Alloys and Compounds, 2018, 762: 719.

[15]YANG Q S, JIANG B, HE J J, et al. Tailoring Texture and Refining Grain of Magnesium Alloy by Differential Speed Extrusion Process[J]. Materials Science and Engineering: A, 2014, 612:187.

[16]WANG Q , SONG J , JIANG B , et al. An Investigation on Microstructure, Texture and Formability of AZ31 Sheet Processed by Asymmetric Porthole Die Extrusion[J]. Materials Science and Engineering: A, 2018, 720:85.

[17]ORLOV D, RAAB G, LAMARK T T, et al. Improvement of Mechanical Properties of Magnesium Alloy ZK60 by Integrated Extrusion and Equal Channel Angular Pressing[J]. Acta Materialia, 2011,59:375.

[18]ORLOV D, RALSTON K D, BIRBILIS N, et al. Enhanced Corrosion Resistance of Mg Alloy ZK60 after Processing by Integrated Extrusion and Equal Channel Angular Pressing[J]. Acta Materialia, 2011, 59(1):6176.

[19]HU H J, WANG H, ZHAI Z Y, et al. Effects of Channel Angles on Extrusion-shear for AZ31 Magnesium Alloy Modeling and Experiments[J]. The International Journal of Advanced Manufacturing Technology, 2015,76(9/12): 1621.

[20]KHODDAM S, FARHOUMAND A, HODGSON P D. Axi-symmetric Forward Spiral Extrusion, a Kinematic and Experimental Study[J]. Materials Science and Engineering: A, 2011, 528(3): 1023.

[21]SHAHBAZ M, PARDIS N, KIM J G, et al. Experimental and Finite Element Analyses of Plastic Deformation Behavior in Vortex Extrusion[J]. Materials Science and Engineering: A, 2016, 674: 472.

[22]LU L W, LIU C, ZHAO J, et al. Modification of Grain Refinement and Texture in AZ31 Mg Alloy by a New Plastic Deformation Method[J]. Journal of Alloys and Compounds, 2015,628:130.

[23]LI F, ZENG X, BIAN N. Microstructure of AZ31 Magnesium Alloy Produced by Continuous Variable Cross-section Direct Extrusion(CVCDE)[J]. Materials Letters, 2014,135:79.

[24]LI F, ZENG X, CAO G J. Investigation of Microstructure Characteristics of the CVCDEed AZ31 Magnesium Alloy[J]. Materials Science and Engineering A, 2015, 639:395.

[25]MLLER S, DENKS I, MLLER K, et al. Extrusion of Magnesium Profiles and Microstructure Characterization[C]// Magnesium: Proceedings of the 6th International Conference Magnesium Alloys and Their Applications, December, 2003:254.

[26]WANG Y P, LI F, SHI W Y, et al. Dynamic Recrystallization and Metal Flow Behavior of AZ31 Magnesium Alloy Bending Products Processed by Staggered Extrusion[J]. Journal of Materials Engineering and Performance, 2019,28(6): 3551.

[27]WANG Q S, JIANG B, CHAI Y F, et al. Tailoring the Textures and Mechanical Properties of AZ31 alloy Sheets Using Asymmetric Composite Extrusion [J]. Materials Science and Engineering: A, 2016, 673: 606.

[28]PAN F S, WANG Q H, JIANG B, et al. An Effective Approach Called the Composite Extrusion to Improve the Mechanical Properties of AZ31 Magnesium Alloy Sheets [J]. Materials Science and Engineering:A,2016, 655: 339.

[29]MLLER, KLAUS B. Indirect Extrusion with Active Friction(ISA)[J]. Key Engineering Materials, 2002(233/236):323.

[30]SOCACIU T. Experimental Study Regarding Variation of Force in Inverse Extrusion Using Active Friction[J]. Procedia Technology, 2015, 19:85.

[31]MA X, BARNETT M R, KIM Y H. Forward Extrusion Through Steadily Rotating Conical Dies. Part I: Experiments[J]. International Journal of Mechanical Sciences,2004,46(3):449.

[32]MA X, BARNETT M R, KIM Y H. Forward Extrusion Through Steadily Rotating Conical Dies.Part II: Theoretical Analysis[J]. International Journal of Mechanical Sciences, 2004, 46(3):465.

[33]Kong L X, Lin L, Hodgson P D. Material Properties under Drawing and Extrusion with Cyclic Torsion[J]. Materials Science and Engineering A,2001,308(1/2):209.

[34]MACIEJEWSKI J, MRóZ Z. An Upper-bound Analysis of Axisymmetric Extrusion Assisted by Cyclic Torsion[J]. Journal of Materials Processing Technology,2008,206 (1/3):333.

[35]JAHEDI M, PAYDAR M H. Study on the Feasibility of the Torsion Extrusion(TE) Process as a Severe Plastic Deformation Method for Consolidation of Al Powder[J]. Materials Science and Engineering A,2010,527(20): 5273.

[36]YASUMASA C, HUANG X, KAZUTAKA S, et al. Texture and Mechanical Properties of Mg-3Al-lZn-0.5Mn-l.5Ca Alloy Produced by Torsion Extrusion[J]. Materials Transactions, 2010, 51(5):872.

[37]CHINO Y , SASSA K , MABUCHI M. Enhancement of Tensile Ductility of Magnesium Alloy Produced by Torsion Extrusion[J]. Scripta Materialia, 2008,59(4):399.

[38]WANG J, ZHANG D, LI Y, et al. Effect of Initial Orientation on the Microstructure and Mechanical Properties of Textured AZ31 Mg Alloy During Torsion and Annealing[J]. Materials and Design, 2015, 86: 526.

[39]WANG J, YANG XY, LI Y , et al. Enhanced Ductility and Reduced Asymmetry of Mg-2Al-1Zn Alloy Plate Processed by Torsion and Annealing[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(12): 3928.

[40]LI F, CHU G N, LIU E L, et al. Investigation of Metal Extrusion Forming Through Steadily Rotating Container[J]. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, 2011,225(12):2927.

[41]LI F, BIAN N, XU Y C, et al. Theoretical Analysis of Extrusion Through Rotating Container: Torque and Twist Angle[J]. Computational Materials Science, 2014, 88(6): 37.

[42]YU J M, ZHANG Z M, WANG Q, et al. Rotary Extrusion as a Novel Severe Plastic Deformation Method for Cylindrical Tubes[J]. Materials Letters,2018,215:195.

[43]LIN J, XIA X, CHEN Q. An Investigation of the Variable Cross-section Extrusion Process[J]. International Journal of Advanced Manufacturing Technology, 2017, 91(1/4): 453.

[44]胡水平, 李少鋒, 任學平, 等. 連續變斷面擠壓工藝的開發[J]. 機械工程學報, 2005,41 (12):173.

[45]胡水平, 高曉丹, 任學平, 等. 連續變斷面擠壓制品組織的變化規律[J]. 北京科技大學學報, 2008,30(7): 751.

[46]LI F, JIANG H W, CHEN Q, et al. New Extrusion Method for Reducing Load and Refining Grains for Magnesium Alloy[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1/4):73.

[47]LIU Y, LI F, JIANG H W. Microstructural Analysis and Mechanical Properties of AZ31 Magnesium Alloy Prepared by Alternate Extrusion (AE)[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(9/12): 4293.

(編輯:溫澤宇)