扒雞加工過程中揮發性風味物質的變化規律

李儒仁 陳雨 張慶永 顧明月 崔曉瑩 楊文昇 趙志南 榮良燕 劉登勇

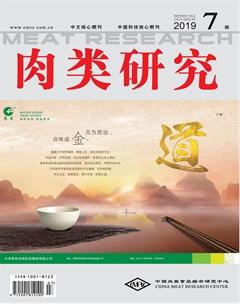

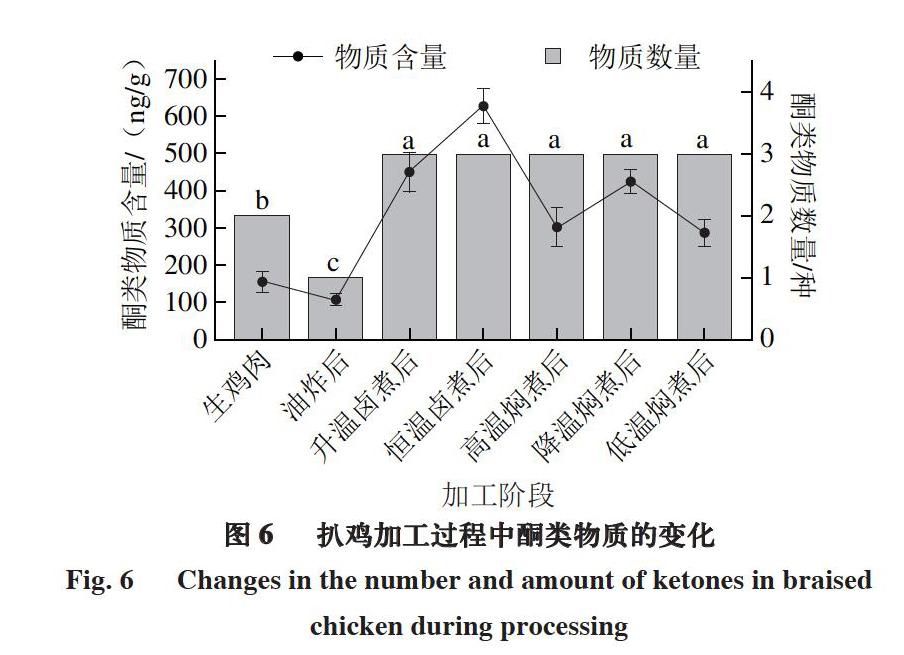

摘 要:為探究扒雞加工過程中風味物質的變化規律,以德州扒雞為研究對象,采用固相微萃取結合氣相色譜-質譜聯用(solid phase microextraction-gas chromatography-mass spectrometry,SPME-GC-MS)技術測定其加工過程中的風味物質,并通過氣味活度值(odor activity value,OAV)分析它們的貢獻。結果表明:從扒雞加工過程的7 個采樣點共檢測到56 種風味物質,其中醛類7 種、醇類11 種、烴類27 種、酮類4 種、雜環化合物2 種、醚類2 種、酚類1 種、酯類1 種、含硫化合物1 種;扒雞的主要揮發性風味物質為醛類、醇類、烴類和酮類;加工過程中,各類風味物質含量總體上呈先增加后降低的趨勢,鹵制階段揮發性風味物質的數量和含量顯著增加(P<0.05),恒溫鹵煮后風味物質含量達到最大;二甲基二硫、己醛、壬醛、庚醛、1-辛烯-3-醇、2-戊基呋喃、D-檸檬烯、桉葉油醇和丁香酚的OAV>10,表明這些物質對扒雞整體風味貢獻較大,其主要來源于加工過程中不飽和脂肪酸的氧化及鹵制時添加的香辛料。綜上,鹵制是扒雞風味物質形成的關鍵加工階段。

關鍵詞:扒雞;加工過程;揮發性風味物質;變化規律

Changes in Volatile Flavor Compounds of Dezhou Braised Chicken during Processing

LI Ruren1, CHEN Yu1, ZHANG Qingyong2, GU Mingyue1, CUI Xiaoying1, YANG Wensheng1, ZHAO Zhinan1, RONG Liangyan1, LIU Dengyong1,3,*

(1.National and Local Joint Engineering Research Center of Storage, Processing and Safety Control Technology for

Fresh Agricultural and Aquatic Products, College of Food Science and Technology, Bohai University, Jinzhou 121013, China;

2.Shandong Dezhou Braised Chicken Co. Ltd., Dezhou 253003, China;

3.Collaborative Innovation Center of Meat Production and Processing, Quality and Safety Control, Nanjing 210095, China)

Abstract: The changes of volatile flavor compounds during the processing of Dezhou braised chicken were determined by solid phase microextraction-gas chromatography-mass spectrometry (SPME-GC-MS) and based on the odor activity value (OAV), the flavor contribution of each was evaluated. The results showed that a total of 56 flavor compounds were detected at 7 stages of processing, including 7 aldehydes, 11 alcohols, 27 hydrocarbons, 4 ketones, 2 heterocyclic compounds,

2 ethers, 1 phenol, 1 ester, and 1 sulfur-containing compound. The main volatile flavor compounds were aldehydes, alcohols, hydrocarbons, and ketones. The content of each class of flavor compounds increased at first and then decreased during processing. The number and amount of volatile flavor compounds in the stewing stage increased significantly (P < 0.05). The maximum amount of volatile flavor compounds was attained after the temperature remained constant. The OAVs of dimethyl disulfide, hexanal, nonanal, heptanal, 1-octene-3-ol, 2-pentylfuran, D-limonene, eucalyptol and eugenol were all greater than 10. These compounds contributed significantly to the flavor of braised chicken, mainly coming from the oxidation of unsaturated fatty acids and the spices used during processing. In summary, stewing was critical for the formation of flavor compounds of braised chicken.

Keywords: braised chicken; processing; volatile flavor compounds; changes

DOI:10.7506/rlyj1001-8123-20190505-097

中圖分類號:TS251.1? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?文獻標志碼:A 文章編號:1001-8123(2019)07-0049-07

引文格式:

李儒仁, 陳雨, 張慶永, 等. 扒雞加工過程中揮發性風味物質的變化規律[J]. 肉類研究, 2019, 33(7): 49-55. DOI:10.7506/rlyj1001-8123-20190505-097.? ? http://www.rlyj.net.cn

LI Ruren, CHEN Yu, ZHANG Qingyong, et al. Changes in volatile flavor compounds of Dezhou braised chicken during processing[J]. Meat Research, 2019, 33(7): 49-55. DOI:10.7506/rlyj1001-8123-20190505-097.? ? http://www.rlyj.net.cn

醬鹵肉制品作為我國傳統肉制品之一,是以鮮(凍)畜禽肉和可食副產品為原料,浸入加有食鹽、香辛料和醬油(或不加)等的水中,經預煮、燒煮和醬制(鹵制)等工藝加工而成[1]。扒雞是醬鹵肉制品的典型代表,其制作時選用優質胴體雞,經油炸后在老湯中先鹵后燜,同時對加工過程中每一階段的溫度與時間進行嚴格控制[2]。這種特殊工藝賦予扒雞獨特的風味,使其深受廣大消費者的青睞。……