真空干泵用定子拼裝式永磁電機性能分析與實驗

安躍軍 楊維國 胡鑫 黃鑫 王光玉 孔祥玲 畢德龍

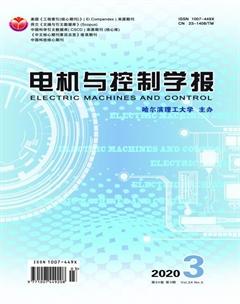

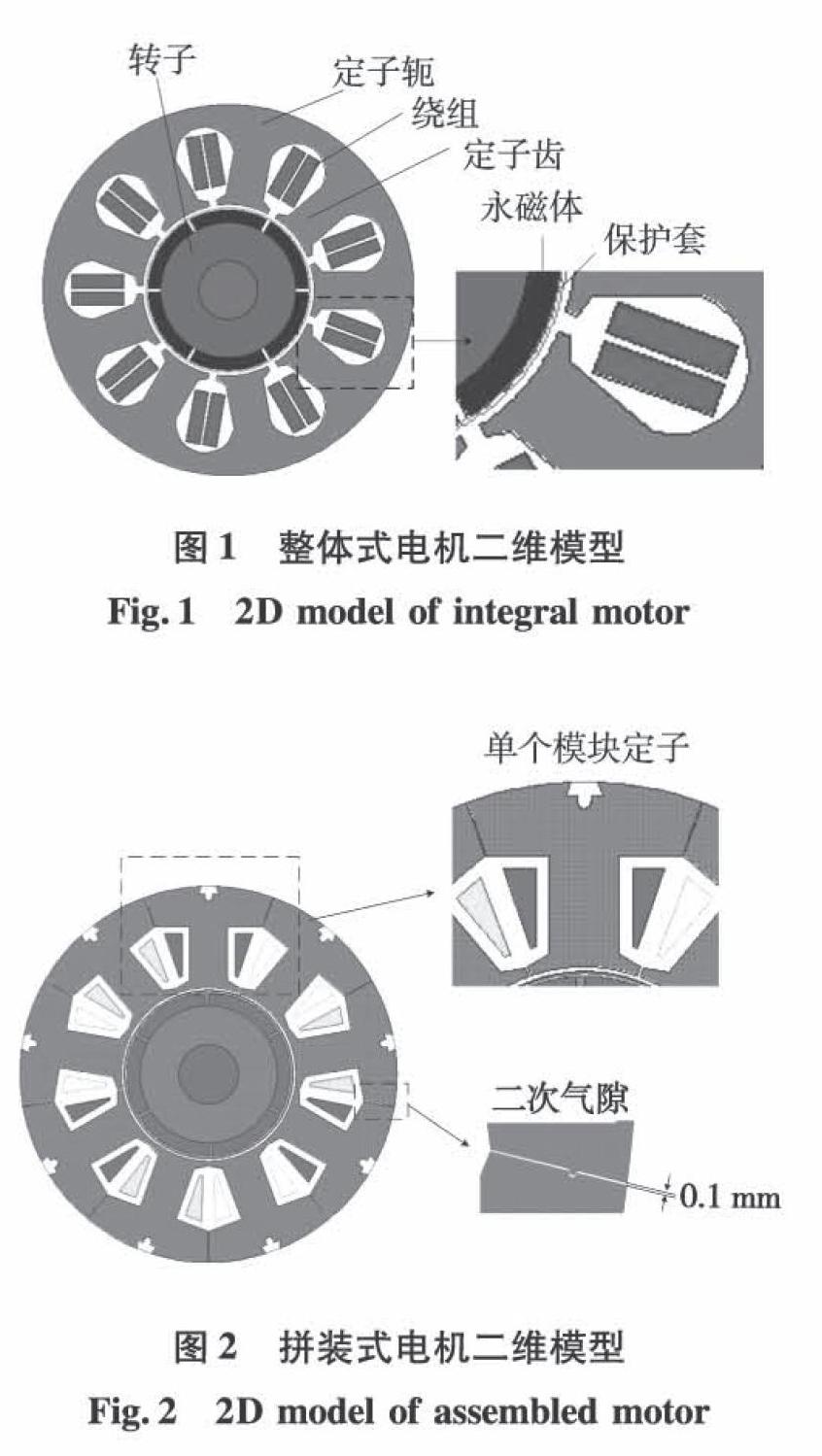

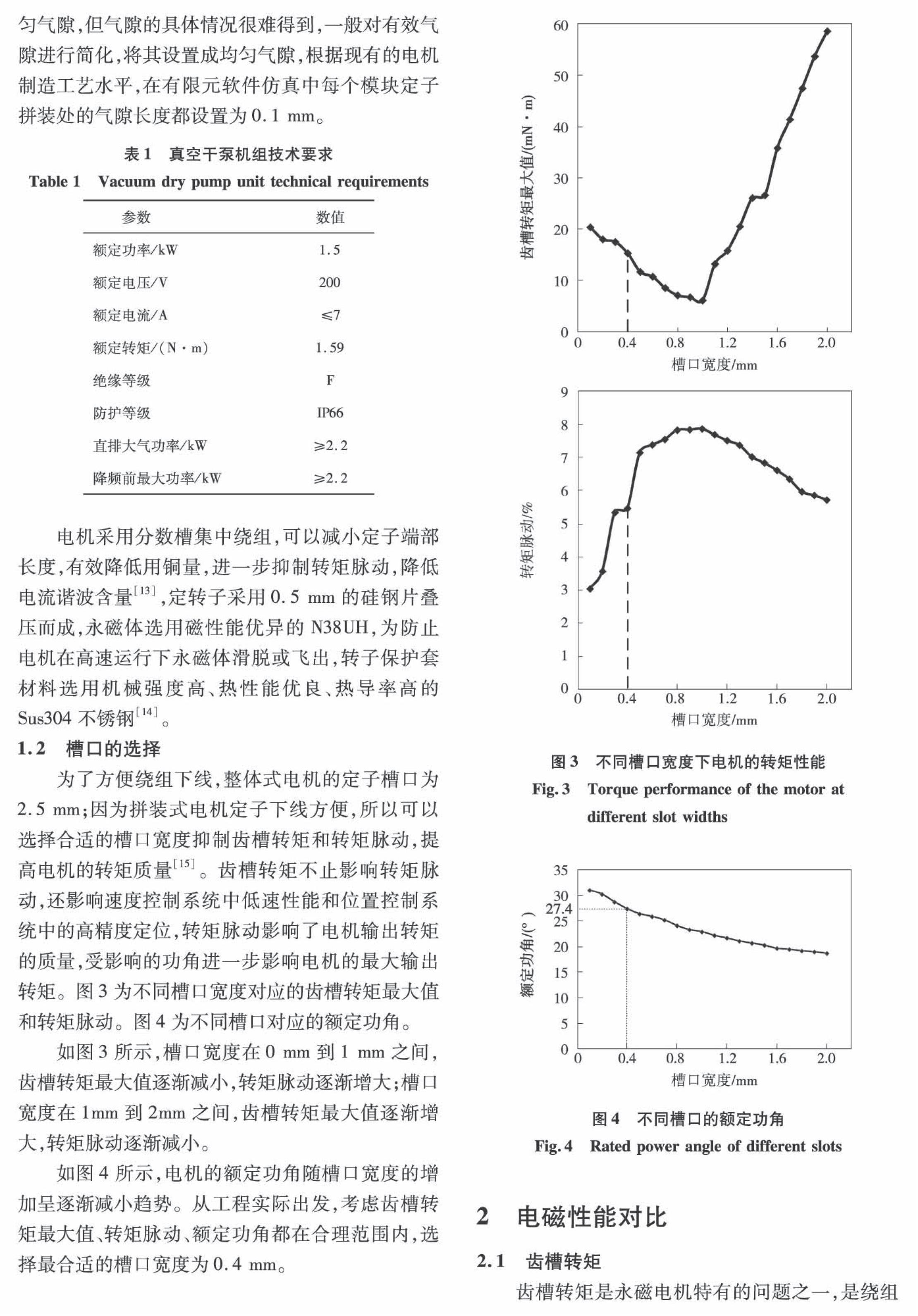

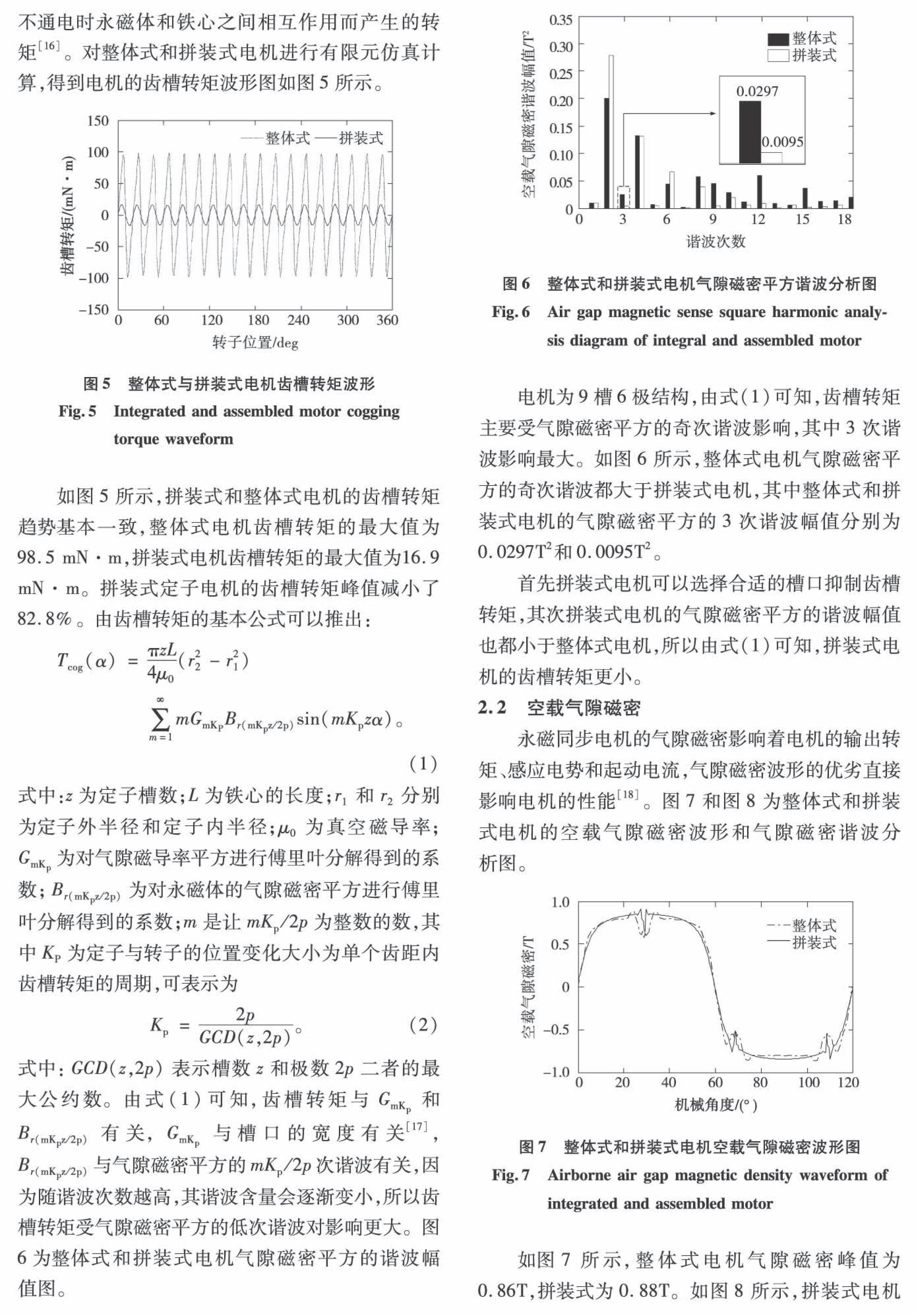

摘 要:針對小型真空干泵用永磁電機下線困難的工程問題,提出一種采用模塊化定子結構方法,將定子形式由整體式變為拼裝式,并以9槽6極表貼式永磁同步電機為研究對象,采用有限元法選取抑制拼裝式電機齒槽轉矩和轉矩脈動的的最優槽口,引入整體式電機進行對比,建立拼裝式與整體式電機的二維模型,并進行電磁場與溫度場仿真,綜合分析拼裝式與整體式電機的性能差異,結果表明拼裝式電機的齒槽轉矩、氣隙磁密諧波含量和溫升等都優于整體式電機。研制拼裝式電機的樣機并進行電機性能實驗,得到了電機的性能數據。實驗結果與仿真結果一致,進一步驗證了拼裝式電機的可行性,為新產品批量生產提供了科學依據。

關鍵詞:真空干泵;拼裝式定子;齒槽轉矩;溫度場;性能實驗

DOI:10.15938/j.emc.2020.03.014

中圖分類號:TM 351文獻標志碼:A文章編號:1007-449X(2020)03-0114-09

Abstract:Aiming at the problem of smallscale vacuum dry pump permanent magnet motors going offline, a modular stator structure method is proposed to change the stator form from monolithic to assembled, and a 9slot 6pole surfacemounted permanent magnet synchronous motor is chosen as the research object. The optimal slot for suppressing cogging torque and torque ripple of the assembled motor was selected by the finite element method, and the integrated motor was introduced for comparison. A twodimensional model of the assembled and integrated motor was established, and the electromagnetic field was performed. With the temperature field simulation, comprehensive analysis of the performance difference of the assembled and integrated motors, the results show that the cogging torque, air gap magnetic flux harmonic content and temperature rise of the assembled motor are better than the integrated motor. The prototype of the assembled motor was developed and the motor performance experiments were performed to obtain the performance data of the motor. The experimental results are consistent with the simulation results, further verifying the feasibility of the assembled motor, and providing a scientific basis for mass production of new products.

Keywords:vacuum dry pump; assembled stator; cogging torque; temperature field; performance experiment

0 引 言

隨著真空技術的不斷的發展,真空獲得設備在航空航天、食品加工、醫療、國防、電子等行業都有了廣泛的應用[1]。傳統真空系統是有油的,并且在生產過程中產生的物質具有腐蝕性、凝結性和毒性,這些物質與真空泵中的油相混合,會造成真空泵泵油變質,由工藝過程中產生的化學產物和顆粒副產物也會影響真空泵的性能,使真空泵不能運行破壞本身以及周邊的環境[2]。傳統的真空系統已經不能滿足實際工況的要求,所以研究具有可靠性高、適應性強、無污染的真空干泵已經是真空獲得設備的一個重要的方向[3]。

真空干泵驅動電機的性能直接影響了真空干泵的過載能力、振動噪聲、極限真空度以及能耗等級[4]。驅動電機一般采用異步電機和永磁同步電機,采用異步電機,會導致真空干泵體型大、噪聲大、耗能高,且只能使用于工作空間充裕的場合。隨著人們對節能、高效、空間利用率的要求越來越高,為適應晶圓廠等生產空間有限的應用場合,研究體積小、低振動、低噪音的新型結構永磁同步電機作為真空干泵驅動電機具有重要的工程實用價值。

目前對拼裝式電機的研究如下,文獻[5]提出了一種定子的新型結構,通過計算定子單個模塊所需的最小槽數,以及相對應的繞組短距系數,從而提高了的繞組的利用率;文獻[6-7]利用有限元法研究一種繞組不等拼裝式定子結構,求解出單邊磁拉力,并以改變拼裝式定子齒寬和定子之間位置差結構有效的減小了合成磁拉力;文獻[8-10]通過計算不同形狀定子拼裝處凹槽電機齒槽轉矩大小來選擇效果最好的形狀;文獻[11]設計了一臺定子新型結構的永磁電機,并優化了電機的轉矩密度;文獻[12]設計定子形式為拼裝式的電機,將電路、磁路負荷分別計算進行優化,從而有效的提高了電機的轉矩密度和效率。但是,電機性能受氣隙磁密、損耗、溫度等影響,上述文獻均沒有針對這些問題做深入研究。

[11] 吉敬華,孫玉坤,朱紀洪,等.模塊化永磁電機的設計分析與實驗[J].電工技術學報, 2010, 25(2):22.

JI Jinghua, SUN Yukun, ZHU Jihong, et al. Design analysis and experiment validation of a modular permanent magnet machine [J]. Transactions of China Electrotechnical Society, 2010, 25(2): 22.

[12] 顏建虎,汪盼,費晨.模塊化開關磁阻式橫向磁通電機設計與分析[J].中國電機工程學報, 2018, 38(22):270.

YAN Jianhu, WANG Pan, FEI Chen. Design and analysis of modular switched reluctance transverse flux motor[J]. Proceedings of the CSEE, 2018, 38(22): 270.

[13] ALBERTI L, BARCARO M, BIANCHI N. Design of a lowtorqueripple fractionalslot interior permanentmagnet motor [J]. IEEE Transactions on Industry Applications, 2012, 50(3):1801.

[14] 安躍軍,殷福久,王光玉,等.真空泵屏蔽電動機溫度場與屏蔽套應力場分析[J].沈陽工業大學學報,2016, 38(2):121.

AN Yuejun, YIN Fujiu, WANG Guangyu, et al. Analysis for temperature field and can stress field ofvacuum pump canned motor [J]. Journal of Shenyang University of Technology, 2016, 38(2): 121.

[15] 郭淑英,李坤,彭俊.采用分數槽繞組降低永磁同步電機齒槽轉矩的研究[J].大功率變流技術,2013(1):56.

GUO Shuying, LI Kun, PENG Jun. Study on reducing cogging torque of permanent magnet synchronousmotor with fractionalslot windings [J]. High Power Converter Technology, 2013(1): 56.

[16] HEINS G, BROWN T, THIELE M. Statistical analysis of the effect of magnet placement on cogging torque in fractional pitch permanent magnet motors [J]. IEEE Transactions on Magnetics, 2011, 47(8):2142.

[17] 張琪,梁冰潔,黃蘇融,等.槽口寬度對分數槽集中繞組永磁電機齒槽轉矩的影響[J].電機與控制應用, 2015(7):1.

ZHANG Qi, LIANG Bingjie, HUANG Surong, et al. Effect ofslot opening on cogging torque of permanent magnet synchronous motor with fractionslot concentrated winding [J]. Electric Machines and Control Application, 2015(7):1.

[18] 李爭,聶雅盟,薛增濤,等.液質懸浮式三自由度電機電磁特性的計算分析[J].電機與控制學報,2017(4):16.

LI Zheng, NIE Yameng, XUE Zengtao, et al. Calculation and analysis of electromagnetic characteristics of liquid suspension type threedegreeoffreedom motor [J]. Electric Machines and Control, 2017(4):16.

[19] 裴鋒,薛勇.定子焊槽對永磁電機空載反電勢的影響[J].微特電機, 2015,43(6):16.

PEI Feng, XUE Yong. Influence of stator core welding slots on pm motor's noload of back emf [J]. Small & Special Electrical Machines, 2015, 43(6):16.

[20] 梁艷萍,李偉,王澤宇,等.高速感應電機轉子渦流損耗的計算方法及影響因素[J].電機與控制學報,2019, 23(5):42.

LIANG Yanping, LI Wei, WANG Zeyu, et al. Calculation method and effect factors of eddy current losses in rotor of high speed induction motor [J]. Electric Machines and Control, 2019, 23(5):42.

[21] 安躍軍,張強,李文瑞,等.新型移相式屏蔽電動機屏蔽套渦流與溫升分析[J].西安交通大學學報,2014, 48(6):50.

AN Yuejun, ZHANG Qiang, LI Wenrui, et al.Eddy losses and temperature rise on shielded can in canned motor with new phaseshifted structure [J]. Journal of Xi'an Jiaotong University, 2014, 48(6): 50.

[22] 安躍軍,張振厚,張強,等.干式渦旋真空泵用特種電機溫度場仿真與實驗[J].電機與控制學報,2017, 21(8):48.

AN Yuejun, ZHANG Zhenhou, ZHANG Qiang, et al. Temperature field simulation and experiment of special motor for dry scroll vacuum pump [J]. Electric Machines and Control, 2017, 21(8): 48.

(編輯:賈志超)