Study on High Power Hall Electric Propulsion Technology

HANG Guanrong ,ZHAO Zhen ,YU Shuilin ,QIAO Caixia,LIU Jia HUANG Hao,TIAN Leichao,LI Lin,LI Wenshuai,KANG Xiaolu

1 Shanghai Institute of Space Propulsion,Shanghai 201112

2 Shanghai Engineering Research Center of Space Engine,Shanghai 201112

Abstract:High power Hall electric propulsion technology is a very competitive electric propulsion technology for future large space missions such as large GEO satellites,manned space programs,deep space explorations,cargo ships,space tugs.Based on the experience of more than 20 years in research and development of Hall electric propulsion,the Shanghai Institute of Space Propulsion (SISP) has developed 3 high power Hall thrusters,i.e.,the 10 kW class HET-500,20 kW class HET-1000,and 50 kW class HET-3000.This paper presents the development status of the high power (≥10 kW) Hall electric propulsion at SISP,including tests of 3 high power Hall thrusters in the power range from 10 kW to 50 kW,the qualification of a single string of a 10 kW Hall electric propulsion system,and the study of a cluster of two 1.35 kW HET-80 Hall thrusters to understand the technical issues related to multi-thruster high power electric propulsion systems.

Key words:high power,Hall electric propulsion,Hall thruster,single string system integration,thruster cluster

1 INTRODUCTION

Shanghai Institute of Space Propulsion (SISP) majors in space propulsion technology,developing corresponding propulsion systems and thrusters that have been widely used in manned space missions,satellites,cargo spacecraft,and lunar explorers.SISP started the development of Hall electric propulsion technology in 1994 and developed the first Hall thruster and the Hall electric propulsion system in China.From 2012 to 2014,SISP completed the first in-orbit flight demonstration of Hall electric propulsion in China[1].Since then,the main efforts of SISP in the domain of electric propulsion have been paid to the application of medium power Hall electric propulsion,and the research and qualification of key technologies related to high power Hall electric propulsion[2].

SISP has developed 10 kW class HET-500,20 kW class HET-1000 and 50 kW class HET-3000 high power Hall thrusters since 2016.The performance of the HET-500 and the HET-1000 were evaluated.The highest thrust and specific impulse of the HET-1000 exceeded 1 N and 3300 s respectively.The HET-3000 thruster was tested at a low power of 15 kW to verify the design architecture.A single string of 10 kW Hall electric propulsion system,including a HET-500 thruster,a pressure regulation module (PRM),a xenon flow control module (XFCM),a power processing unit (PPU) and a digital control interface unit (DCIU),was integrated and validated under a system level firing test.

2 HIGH POWER HALL THRUSTER DEVELOPMENT

The nominal design values of the HET-500,HET-1000 and HET-3000 are shown in Table 1.In order to improve the thruster life dramatically,the latest magnetic shielding technology[3,4]was applied to all of these thrusters.The principle of the magnetic shielding technology is shown in Figure 1.In principle,the near-wall magnetic lines are designed to parallel to the discharge chamber wall at the chamber exit,and hence the magnetic force lines are equipotential.Ions are restricted topass through the discharge channel wall sheath,thereby significantly reducing the ion-bombardment erosion of the channel wall and high-energy electron power deposition to the wall.The magnetic shielding effects have already been applied to two previously designed thrusters,namely the 3 kW class HET-200 thruster and the 5 kW class HET-300 thruster.

Table 1 Nominal design values of 3 high power Hall thrusters

Figure 1 The principle of magnetic shielding technology(modified from [4])

2.1 10 kW Class Hall Thruster

After the successful development of the 5 kW class HET-300 multimode Hall thruster flight model in 2016,researchers at SISP developed a 10 kW class Hall thruster,HET-500.The HET-500 is mainly designed for missions such as 5-ton class all-electric GEO satellites,8-ton class GEO satellites,large robotic space probes,and spaceships.Figure 2 is the HET-500 thruster and firing image.

To achieve a wide throttle range and to reduce cost,the discharge chamber was designed as a compound structure.The upstream parts near the anode are made of metal and the chamber exit parts BN/SiO2 ceramic.

Figure 2 HET-500 thruster before operation and its firing image

The performance evaluation was conducted in VF-6 chamber at SISP,shown in Figure 3.The inner dimension of VF-6 chamber isΦ4 m×8 m.To achieve high vacuum,the VF-6 is equipped with cryopumps and xenon pumps.

The nominal and envelope performance characteristics of the HET-500 were measured.The thrust and specific impulse were 511 mN and 2506 s respectively at a power of 10.189 kW.

The HET-500 was then evaluated over the range of 300-900 V and 0.78-12.5 kW.The thrust and specific impulse covered 38.6-606 mN and 1225-3213 s.The highest efficiency was 63.46% at 900 V.The power throttle range 16:1.

As the solar panel power is approximately inversely proportional to the square of the distance between the spacecraft and the sun[5],this throttle range means that the HET-500 could support a solar powered spacecraft from the Earth to the main asteroid belt.The main asteroid belt is at a distance of 2.10 to 3.64 astronomical units from the sun.

After the performance evaluation tests,a preliminary examination of the magnetic shielding effect was conducted by the appearance inspection of the chamber exit walls comprised of white ceramic material.Figure 4 shows the inner and outer chamber exit walls after performance evaluation tests of about 6 hours.The photo shows that both the walls turned from white to a uniform light dark.This means that the back-sputtered carbon atoms coated to the wall and the coating speed was faster than the rate of ion erosion of the wall.So the magnetic shielding design to prolong the thruster life was successful.

Figure 3 The VF-6 chamber

Figure 4 The chamber exit of the HET-500 thruster after the performance evaluation tests of about 6 hours

2.2 20 kW Class Hall Thruster

The 20 kW Hall thruster,the HET-1000,is the first newtonclass-thrust Hall thruster in China.The target missions of the HET-1000 include deep space exploration and cargo spacecraft.

In order to improve electron utilization and to increase efficiency,the hollow cathode of the HET-1000 is located in the center,as there is enough space on the axis of the inner magnetic pole.This thruster is the first Hall thruster with a center mounted cathode at SISP.

The nominal discharge current of the hollow cathode of HET-1000 is 40 A,and the current adjustment range covers 10-50 A[6].This ensures that the HET-1000 could throttle over a wide range.

The performance of HET-1000 was preliminarily evaluated in mid-December,2019.The accumulated firing time exceeded 8 hours with over 30 ignitions.The thruster was evaluated over the range of 450-700 V and 10-20 kW.

The highest thrust was 1070 mN at 20 kW,450 V.The thrust,specific impulse and efficiency ranged from 510-1070 mN,2479-3301 s and 63.9%-73.2%,respectively.

The tests confirmed that the centered mounted cathode can increase the overall efficiency of the thruster as more electrons can be trapped compared to a side mounted hollow cathode[7].Figure 6 confirms the satisfactory magnetic shielding effect after tests of more than 8 hours.

Figure 5 HET-1000 thruster before operation and its firing image

Figure 6 The chamber exit of the HET-1000 thruster after tests of more than 8 hours

2.3 50 kW Class Hall Thruster

The 50 kW class Hall thruster,the HET-3000,was designed mainly for large-scale crewed missions,cargo transportation missions to the moon and Mars.Figure 7 is the HET-3000 thruster and its firing image.

Just like the HET-500,the discharge chamber is a compound one with upstream metal parts and downstream ceramic parts at the chamber exit.Alike the HET-1000,the 100 A high current cathode is center mounted.

Because of the limitation of the VF-6 chamber pumping capability,the HET-3000 was fired in a low power mode of 15 kW to verify the design architecture.

Figure 7 HET-3000 thruster before operation and firing image at low power

Because of the high current,both BaO and LaB6 emitter cathodes were designed and they have the same appearance and interface.Both cathodes can emit a current of 25-120 A at a xenon flow rate of 20-55 sccm[8].This will ensure a wide throttle range for the HET-3000.

3 STUDY ON THE HIGH POWER HALL ELECTRIC PROPULSION SYSTEM

While developing high power Hall thrusters,SISP is also conducting research on high power Hall electric propulsion system technology.Up to now,two studies have been completed.One was for a single integration validation of a 10 kW high power electric propulsion system.Another was for the study of a Hall thruster cluster.

3.1 Single String System Integration Validation of a 10 kW Hall Electric Propulsion System

A single string integration validation of a 10 kW Hall electric propulsion system was conducted.The single system contains a HET-500 thruster,a gas tank,a PRM,a XFCM,a PPU and a DCIU.Figure 8 shows the PRM,XFCM and PPU prototypes.

During the test,the thruster and the XFCM were located in the VF-6 chamber,while the other modules were external in the atmosphere.The pressure of the PRM was adjusted from 0.12 to 0.217 MPa,and the operating power of the HET-500 Hall thruster was between 2.83 to 10.41 kW.

The validation was successful and the research team established the optimum operating parameters which could support the corresponding multi-thruster integration validation.The validation made a key step of the development of high power electric propulsion.

The single string integration test verified three key technologies for the high power Hall electric propulsion system as listed below.

(1) High precision PRM based on a piezoelectric ceramic pressure reducing valve.Compared with a mechanical pressure reducing valve and the Bang-Bang pressure regulating valve,this new kind of electronic regulating valve can ensure higher precision pressure regulating due to its small,steady,quick-response and controllable valve stroke.During the test,the highest pressure regulating precision was better than ±0.5%.

(2) Modular XFCM based on porous metal restrictor:The nominal flow rates of the anode branch and the cathode branch are 19.39 mg/s and 1.02 mg/s,respectively.The configuration of the XFCM is simple.It is mainly composed of 1 inlet,3 solenoid valves,2 thermal valves and 2 outlets.3-D printed parts were employed to reduce the weight and to improve the assembly efficiency.It is very flexible for different applications.Here are two examples,(a) 2 units of XFCMs can be used in parallel,one for primary branch and another as a backup branch; (b) different flow rates can be achieved by replacing porous metal restrictors with different throttling ability,without changing the shape,the layout and the assembly process.

(3) 10 kW class high efficiency PPU:The PPU inherits the design of the PPU for the 5 kW Hall thruster.The input power bus voltage is 100 V and the output discharge voltage is 500 V.During the test,the efficiency of the anode module was about 96%.

Figure 8 PRM,XFCM and PPU prototypes for the single string integration validation

These key technologies were focused to ensure the requirements of modularization,lightness,and a wide throttling range of the high power Hall electric propulsion.

3.2 Preliminary Study of Hall Thruster Cluster

For large space missions such as human deep space exploration,the power of the electric propulsion system may exceed 5 MW[9-10],even up to 500 MW[11].Higher power means shorter transit time to the exploration target.For example,the work done by Franklin.R.Chang Diaz showed that it is possible to transfer to Mars within 39 days with a 200 MW nuclear electric propulsion system[12],while an equivalent impulsive low energy transit employed by current space probes propelled by chemical propulsion would require approximately 250 days.

For the high power electric propulsion system,the optimal number of thrusters is a trade-off between fault tolerance and the increase in mass and cost necessary to support multiple strings.Based on the study result of Richard R.Hofer,et al[13],it is suggested that the optimum configuration of a 500 kW electric propulsion system would be a cluster of 20-50 kW thrusters,and for a 1 MW electric propulsion system a cluster of 50-100 kW thrusters.

In order to understand the performance characteristics of the Hall thruster cluster,SISP conducted a preliminary study of a Hall thruster cluster composed of two 1.35 kW power HET-80 Hall thrusters[14](Figure 9).The HET-80 is designed mainly for station keeping of a 5-ton class GEO satellite,drag compensation for a LEO spacecraft,and the main propulsion for smallscale space probes.The thrust and specific impulse of HET-80 is 80 mN and 1600 s at 300 V.

Three following tasks were conducted:

(1) The performance parameter measurement,including thrust,specific impulse,efficiency and plume divergence angle;

(2) The evaluation of firing stability,plume plasma characteristics,the effect of different thruster gaps and inclinations on thrust,the influence of the magnetic field configuration on the performance of the cluster;

(3) The demonstration of fault reconstruction by firing the cluster with a single cathode,as the cathode is a weakness in the overall stability of electric propulsion system[15].

Seven tests with varying configurations were conducted.These test configurations were the combination of thruster gap,thruster inclination,magnetic field configuration and number of simultaneously working cathodes.

Figure 9 The cluster of 2 HET-80 thrusters

The gap between two thrusters was set to 20 cm and 34 cm.The thrusters were inclined 5° inwardly or outwardly relative to the vertical line of the mounting surface.The magnetic fields of the 2 thrusters were set to same direction or reverse direction.The number of simultaneously working cathodes of all the test conditions was 2,except for the fault reconstruction test condition,which demonstrated one cathode igniting two thrusters.

Figure 10 shows the firing status of the cluster.The cluster operated steadily in 6 test configurations.For the test configuration of 20 cm gap,reverse direction magnetic field,the cluster could not fire steadily because of the intense current oscillation caused by the enhanced magnetic field.From this we can conclude that the minimum gap between the thrusters in the cluster needs to be well-designed.

For the test configurations of same direction magnetic field,compared to a single thruster,the efficiency of the 34 cm-gap cluster is slight higher,while the efficiency of the 20 cm-gap cluster slightly lower.

For the test configurations with an inclination of 5° inward or outward,the thrust of the cluster decreased slightly compared to that of twice the single thruster thrust; The plume divergence angle with outward inclination was 89.6° (90% of total beam),which is slightly larger than the divergence angle of 85.5° (90%of total beam) with an inward inclination at 1 m downstream away the cluster.

Figure 10 Firing status of the cluster

Because high power electric propulsion missions would be very expensive and many missions would be related to humans,the fault reconstruction is very important to improve the reliability of the high power electric propulsion system.As the cathode is a main fault component of the Hall thruster,the capability of two or several thrusters being ignited by a single cathode or one thruster ignited by a cathode of another thruster,will enhance the fault tolerance capability and improve the reliability of the entire mission.

The tests successfully demonstrated the fault reconstruction by firing the cluster with a single cathode (Figure 11).The cluster worked normally with one cathode and the performance did not change significantly.

Figure 11 Fault reconstruction demonstration by one cathode igniting two thrusters

4 CONCLUSIONS AND FUTURE PLAN

As the first research institute to develop Hall electric propulsion technology in China,SISP continues to lead the development of this technology.The successful development of the three high power Hall thrusters and the study of the high power Hall electric propulsion system raise the thrust of the Hall thruster from milli-newton class to newton class in China,and will drive the development of high power electric propulsion technology and its corresponding applications.

SISP will vigorously promote the development of high power hall electric propulsion technology,and the future main planned research directions are as follows:

(1) Maturity enhancement of the existing high power Hall thrusters;

(2) Single Hall thruster with a power up to 100-200 kW for the megawatt class high power electric propulsion system;

(3) High specific Hall thruster with a specific impulse of 6000-8000 s,to dramatically reduce the amount of propellant required;

(4) Nested Hall thruster,to increase the thrust density and throttle capability,and then to reduce the mass and size of the high power electric propulsion system;

(5) Alternative propellants to replace xenon,to significantly reduce the propellant cost and to simplify the propellant storage,supply and in-orbit propellant refueling;

(6) System level reconfiguration,to improve the reliability of the high power electric propulsion system.

- Aerospace China的其它文章

- Progress in Technology of Main Liquid Rocket Engines of Launch Vehicles in China

- The LM-2D Launch Vehicle is Being Hoisted

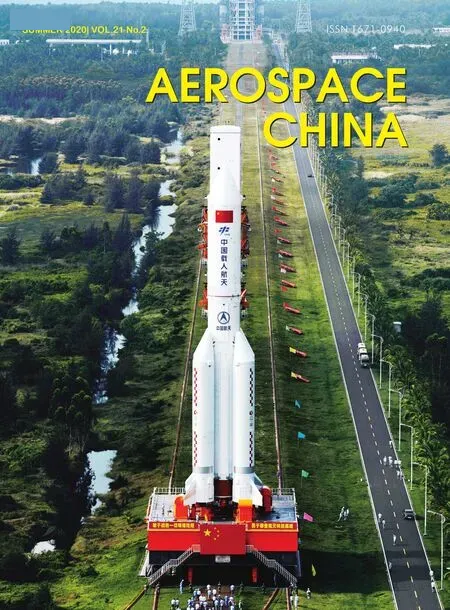

- Maiden Flight of the LM-5B Carrier Rocket

- LM-11 Launched Two New Technology Experimental Satellites

- LM-2D Carried Two Satellites into Space

- LM-2C Launched HY-1D Satellite Successfully