降低CVT變速箱輸出軸圓錐滾子軸承摩擦力矩方法

楊東棟

摘要:用于CVT變速箱輸出軸外側(cè)的圓錐滾子軸承在變速箱臺架耐久試驗70%的循環(huán)時間出現(xiàn)了黏著磨損失效,經(jīng)分析是因軸承摩擦力矩較大引起的。對影響圓錐滾子軸承的摩擦力矩主要因素進(jìn)行分析,對現(xiàn)有結(jié)構(gòu)進(jìn)行優(yōu)化設(shè)計,從而降低滾子與內(nèi)圈擋邊、滾子和滾道的摩擦。經(jīng)過試驗檢測,改進(jìn)后軸承摩擦力矩低于改進(jìn)前摩擦力矩,同時也通過了客戶的變速箱耐久臺架試驗。此次變速箱輸出軸圓錐滾子軸承改進(jìn)案例為圓錐滾子軸承低摩擦設(shè)計提供了依據(jù)。

Abstract: For the tapered roller bearing used for output shaft of CVT gearbox, adhesive wear failureoccurred at 70% cycle time of the transmission stand durability test. Analysis tells that the large friction torqueis the main reason for failure. Analyzing the main factors affecting friction torque of tapered roller bearing, and optimization design for the existing bearing's structure is made to reduce the friction between roller and inner/outer raceway and the friction between roller-end and inner ring's rib. After detection testing, the friction torque of the improved bearing is lower than before. In the meantime, the improved bearing passes the transmission's bench durability test. This case provides a basis for the low friction design of tapered roller bearing.

關(guān)鍵詞:CVT變速箱;圓錐滾子軸承;摩擦力矩;降低

0 ?引言

單列圓錐滾子軸承由內(nèi)圈、外圈、滾動體和保持架組成,能夠承受軸向和徑向的聯(lián)合載荷,承載能力強(qiáng),廣泛應(yīng)用于汽車變速箱和主減速器等承受較大載荷的場合。在為國內(nèi)一家變速箱廠家開發(fā)CVT無級變速箱輸出軸的圓錐滾子軸承時(軸承布置見圖1),輸出軸外側(cè)的圓錐滾子軸承在客戶處進(jìn)行變速箱的耐久臺架試驗時出現(xiàn)了早期失效。客戶要求盡快分析失效原因,并提供新的軸承方案。

1 ?圓錐滾子軸承失效分析

1.1 軸承失效背景描述

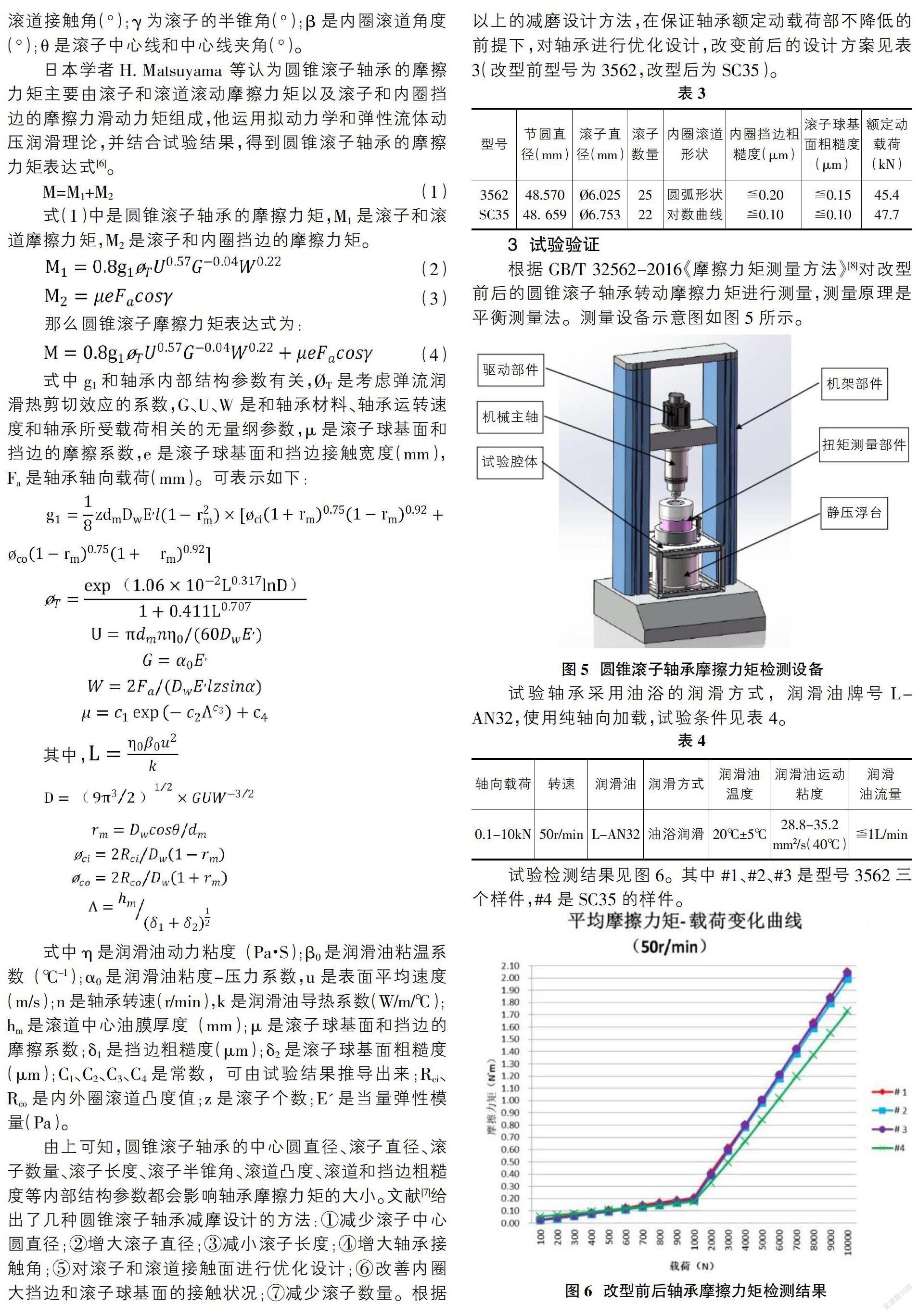

給客戶提供的型號為3562的圓錐滾子軸承在CVT變速箱輸出軸內(nèi)外兩側(cè)各安裝了1套,主軸外側(cè)的圓錐滾子軸承在變速箱臺架試驗循環(huán)的70%時間出現(xiàn)了早期失效。根據(jù)GB/T 24611-2009《滾動軸承損傷和失效術(shù)語、特征及原因》[1]的規(guī)定,判斷該軸承的失效形式為黏著磨損失效。黏著磨損是指材料從一表面轉(zhuǎn)移到另一表面,并伴隨有摩擦發(fā)熱,有時還有回火或重新淬火,這一過程會在接觸區(qū)產(chǎn)生應(yīng)力集中并可能導(dǎo)致開裂或剝落。……