寒潮天氣表冷器-風機集放熱系統對連棟大棚熱濕環境的影響

宗成驥,王平智,2,陳先知,李 明,2,何雪穎,王建玉,徐 丹,2,宋衛堂,2

寒潮天氣表冷器-風機集放熱系統對連棟大棚熱濕環境的影響

宗成驥1,王平智1,2,陳先知3,李 明1,2,何雪穎1,王建玉1,徐 丹1,2,宋衛堂1,2※

(1. 中國農業大學水利與土木工程學院,北京 100083;2. 農業部設施農業工程重點實驗室,北京 100083;3. 溫州科技職業學院,溫州市設施蔬菜工程技術中心,溫州 325000)

設施;溫度;連棟大棚;表冷器-風機;熱濕環境;加溫;除濕

0 引 言

塑料大棚是中國南方地區蔬菜越冬生產主要使用的設施類型,其結構簡單、安裝方便、建設成本低,連棟塑料大棚在其基礎上增加了設施空間,提高了土地利用率,但棚內部依舊僅靠土壤蓄熱,保溫性能也較差,近年來隨著南方地區階段性寒潮(根據現行冷空氣等級國家標準[1],寒潮劃分指標為:使某地日最低氣溫24 h內降溫幅度大于等于8 ℃,或48 h內降溫幅度大于等于10 ℃,或72 h內降溫幅度大于等于12 ℃,而且使該地日最低氣溫下降至4 ℃或以下)的侵襲,棚內作物遭受凍害的現象時有發生[2-4]。為應對寒潮的侵擾,生產上通常采用燃燒生物質塊或者大量蠟燭等方式對大棚進行加溫[5],大面積的燃燒可燃物存在著火災等安全隱患,產生的大量煙氣污染了棚膜,降低了棚內透光率,同時增加了碳排放,嚴重影響棚內外的空氣環境;并且加溫過程不可控,大量的熱能被浪費。因此尋求一種安全、低碳、可控的加溫技術對保證連棟塑料大棚安全越冬生產具有重要意義。

有關設施加溫技術的研究多集中在日光溫室和大跨度外保溫型塑料大棚[6],可分為水循環集放熱[7-12]、空氣循環蓄熱[13-15]、巖床蓄熱[16-17]、相變材料蓄熱[18-20]以及熱泵加溫[21-22]等,以水循環集放熱系統最具代表性,通過水循環將白天溫室內盈余的熱能收集并儲存,夜間再通過循環將儲存的熱能釋放到溫室內,從而達到加溫的目的。這種技術不僅提高了溫室的蓄熱能力,也使得熱能釋放過程可控,放熱效率大幅提高。其中表冷器-風機集放熱系統具有成本低、占用空間小、換熱效率高等優點,可以實現對溫室或大棚內溫度環境的調控[23-27]。表冷器-風機作為集放熱系統的換熱器,主要由風機、盤管等構成,原理就是讓水流過盤管內腔,而待處理的空氣流過盤管外壁進行熱交換來達到加熱或冷卻空氣的目的,而風機引起的強制對流可以增加熱交換的效率。孫維拓等[24]將表冷器-風機與熱泵相結合,夜間平均氣溫升高了2.8~4.4 ℃,相對濕度降低了8.0%~11.5%;李明等[25]針對外保溫塑料大棚,利用表冷器-風機集放熱系統在晴天和多云天氣下將室內氣溫分別提高(2.5±0.4)和(1.1±0.3)℃;何雪穎等[26]基于響應面法研究了風速、水流速度和水氣溫差等參數對表冷器-風機集放熱系統性能的影響。

1 材料與方法

1.1 試驗條件

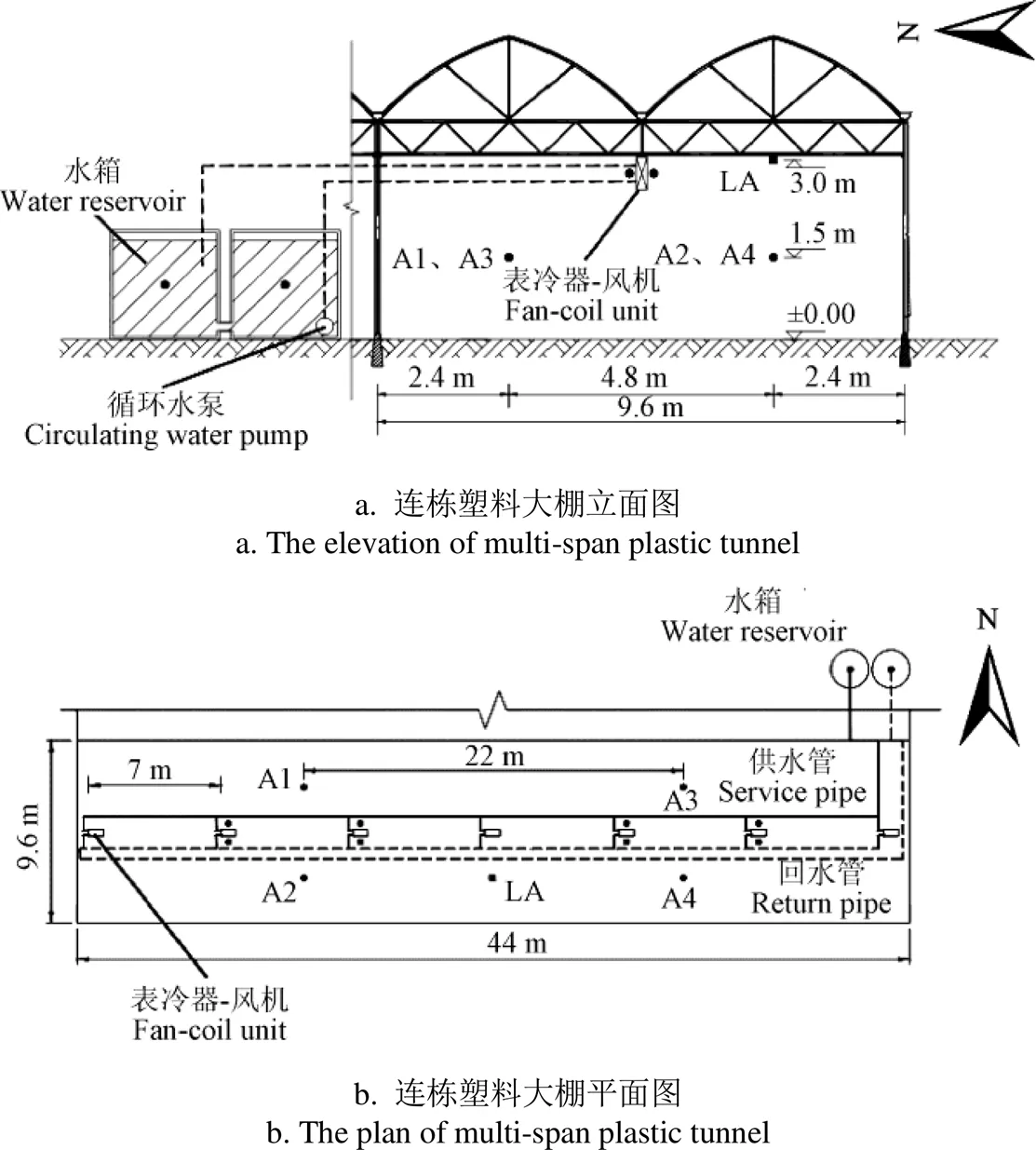

本試驗在溫州市鹿城區藤橋鎮溫州種子種苗科技園(28.1°N,120.5°E)內進行,試驗所用連棟塑料大棚東西走向,長度44 m,共兩跨,一跨有2個雙坡形屋頂,單跨跨度9.6 m,屋脊高度5.5 m。大棚覆蓋0.1 mm厚PO膜,在棚內3 m高處懸掛一層0.1 mm厚PO膜,四周自然垂落至地面,以作二道膜。白天打開兩側通風口及頂部天窗進行自然通風,夜晚關閉。試驗期間大棚內土壤栽培番茄。

表冷器-風機集放熱系統由表冷器-風機、蓄熱水箱、循環水泵、供回水管路及控制系統等組成。表冷器-風機集放熱系統運行過程包括集熱階段和放熱階段,在白天集熱階段表冷器-風機集放熱系統將空氣中盈余的熱量收集并儲存,使蓄熱水箱中的水溫升高;在夜間放熱階段表冷器-風機集放熱系統向棚內空氣釋放熱量,使蓄熱水箱中的水溫降低。夜間放熱階段結束后蓄熱水箱中的水溫偏低,在白天集熱階段開始時,冷水進入表冷器-風機中,棚內熱濕空氣流經表冷器后發生冷凝相變析出冷凝水,這一過程可看作系統對濕空氣進行冷凝除濕。試驗系統配置表冷器-風機共7臺(型號為FNH42,嵊州華昱制冷設備有限公司),均僅懸掛在南側跨大棚桁架下方,每隔4 m設置一臺。根據試驗連棟塑料大棚的大小、覆蓋材料等參數估算冬季采暖系統的熱負荷,并以此為依據計算得到試驗系統配置的蓄熱水箱容積為10 m3,在棚外東北角安裝2個容量為5 m3的圓形不銹鋼保溫水箱用作蓄熱水箱,保溫層為50 mm聚胺脂發泡層,2個水箱通過底側管道聯通。安裝一個型號為40WZB13-18自吸泵作為循環水泵(流量13 m3/h,揚程18 m),各部分由規格為DN63的PPR管連接,采用同程式供回水。

表冷器-風機集放熱系統啟閉條件設定為:當白天棚內氣溫t達到15 ℃或者較蓄熱水箱中水溫t高5 ℃時,系統運行7臺表冷器-風機,通過表冷器-風機收集空氣中盈余的熱能并儲存在蓄熱水箱中,直到氣溫t降至10 ℃或者水氣溫差|t?t|小于2 ℃時,系統關閉;夜晚棚內氣溫t低于2 ℃或者比蓄熱水箱中水溫t低4 ℃時,系統運行4臺表冷器-風機,將蓄熱水箱中的熱量釋放到棚內,直到棚內氣溫t達到5 ℃或者水氣溫差|t?t|小于2 ℃時,關閉系統。

1.2 測點布置

本試驗中空氣溫度使用Pt100鉑電阻(量程:?50~200 ℃,精度:±0.1 ℃)測量,空氣濕度采用SHT35濕度傳感器(量程:0~100%,精度:±2%)測量,如圖1所示,棚內空氣溫濕度由圖中標號A1~A4處傳感器測量數(包括北側跨)取均值所得;從東到西方向上第2、3、5、6臺表冷器-風機進、出風口0.5 m處均各設置一套Pt100及SHT35測量表冷器-風機進、出風口的空氣溫濕度;棚內太陽輻射由圖中標號LA處的YGC-TBQ總輻射傳感器測量(量程:0~2000 W/m2,精度:±10 W/m2);2個圓形保溫水箱中部各安放一個Pt100鉑電阻,取均值作為蓄熱水箱水溫;循環管路的進出水口各安裝一個管道溫度傳感器(Pt100,4分螺紋,桿長100 mm,量程:?50~200 ℃,精度:±0.1 ℃),用以測量系統的進出水溫;棚外氣象條件由氣象站采集,主要包括棚外氣溫、太陽輻照值、濕度以及風速和風向等。以上數據由YC1003型數據采集儀轉化為信號,由RS485通訊傳輸并儲存,采集時間間隔均為5 min;主管道水流量由水表(寧波市三江儀表股份有限公司,精度±2%)測量,手動記錄;系統總耗電量由三相導軌式電能表(量程:45~55 Hz,精度:1級)測量。

注:“A1~A4”表示空氣溫濕度測點,“LA”表示太陽輻射測點。圖示僅為南側跨,北側跨測點布置與南側跨一致。

1.3 評價指標

1.3.1 系統集放熱性能計算方法

表冷器-風機集放熱系統的集放熱性能可以采用集熱量、集熱流量、放熱量以及放熱流量來進行評價,系統的節能性則采用性能系數進行評價[26]。

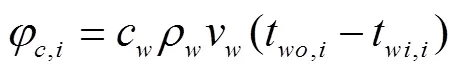

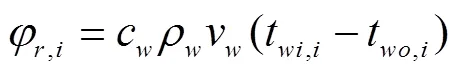

系統的集熱量與集熱流量按照以下公式進行計算[11]:

式中Q為系統集熱量,J;c為水的比熱容,取4 200 J/(kg?℃);為水的密度,取1000 kg/m3;為蓄熱水箱的體積,m3;t為系統開始運行時的蓄熱水箱水溫,℃;t為系統結束運行時的蓄熱水箱水溫,℃;φ為第時刻的系統集熱流量,W;v為系統內循環水流量,m3/s;t為第時刻的系統進口水溫,℃;t為第時刻的系統出口水溫,℃;φ為系統平均集熱流量,W;h為集熱時長,s。

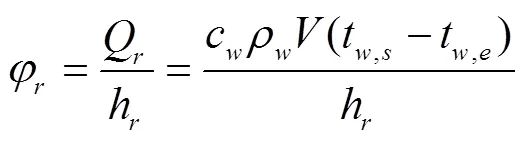

放熱階段可視作集熱階段中能量傳遞的逆向過程,各個因素對放熱階段的影響規律與集熱階段相同,因此系統的放熱量以及放熱流量可以按照下式計算[11]:

式中Q為系統放熱量,J;φ為第時刻的系統放熱流量,W;φ為系統平均放熱流量,W;h為放熱時長,s。

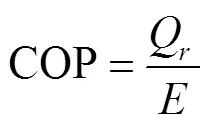

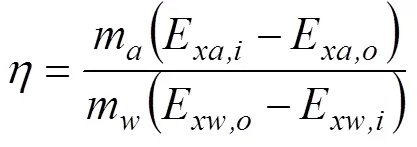

性能系數(Coefficient of Performance,COP)體現了表冷器-風機集放熱系統的節能性,COP越高系統耗能越低,則節能性越好。COP可按照下式計算:

式中為系統運行的耗電量,J。

2 結果與分析

2.1 寒潮下的加溫效果

取2021年1月8日9:00-1月13日9:00共5 d中收集的數據進行分析,這5 d受寒潮連續影響,是氣溫最低的幾日。試驗期間定義白天時間段為7:30-17:30,夜間時間段為17:30-次日7:30。如圖2a所示,受寒潮影響,棚外氣溫較往年記錄低,試驗期間有4 d夜間棚外氣溫在0 ℃以下,后半夜至太陽升起前棚外氣溫逐漸降至最低,最低低至?6.3 ℃,而隨著太陽的升起氣溫會迅速升高,最高可達到14.3 ℃;而白天光照較好,棚內可接收到的最大太陽輻射量為363~446 W/m2,出現在12:00-13:00期間。在這種天氣狀況下,僅靠二道膜保溫已經無法滿足大棚越冬生產的溫度需求。

棚內氣溫變化情況如圖2b所示。隨著太陽升起棚內氣溫迅速增高,達到集熱條件后,系統開始運行將空氣中的熱能收集并儲存,此時氣溫會出現短時間的陡降,接著再繼續上升,隨著兩側和頂部通風窗的打開,棚內氣溫出現一定的波動,最高可達到26~30.6 ℃,有利于表冷器-風機集放熱系統進行集熱;隨著太陽輻射的減弱,棚內氣溫也開始下降,下降至系統關閉條件時,集熱階段結束。由于連棟塑料大棚保溫性能較差,受棚外低溫影響,日落后棚內氣溫迅速下降,當氣溫下降至設定條件時,系統開始運行,放熱階段開始。

1月10日夜間大幅回暖,未啟動表冷器-風機集放熱系統,在棚外最低氣溫2.8 ℃的情況下依靠二道膜保溫使夜間棚內氣溫高于棚外3.3 ℃;其余4夜均進行了放熱,使棚內外溫差達到5.2~7.8 ℃,棚內最低氣溫在2~2.8 ℃,因此表冷器-風機集放熱系統具有良好的加溫效果,可以使棚內作物免遭寒潮等氣溫驟降的不利天氣引起的凍害。

當系統運行時,表冷器-風機出口氣溫遠低于棚內氣溫,由于風機工作加速棚內頂部空氣流動,表冷器-風機的進出口氣溫混合后,進口氣溫t和棚內氣溫t會出現較大的溫差(圖2b),且隨著氣溫的升高溫差逐漸變大,白天棚內氣溫t高于表冷器-風機進口氣溫(3.1±2.2)℃,夜間棚內氣溫t則低于表冷器-風機進口氣溫(1.6±1.5)℃,而系統未運行時表冷器-風機進口氣溫t和棚內氣溫t基本沒有差異,為了保證準確性,在后文性能計算時,水氣溫差指的是表冷器-風機進口氣溫t和蓄熱水箱水溫t的差值|t?t|,而不是系統設定條件中的棚內氣溫t和蓄熱水箱水溫t的差值|t?t|。

2.2 系統集放熱性能分析

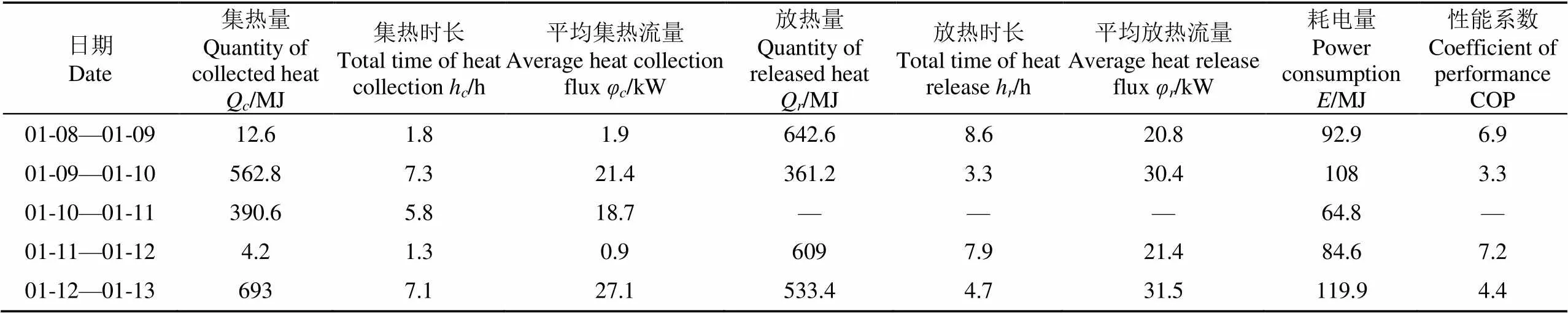

試驗期間水溫變化如圖2b所示,白天隨著系統的運行,系統水溫迅速上升,可達到19.3~22.6 ℃,夜間系統放熱后,水溫最低降至5.2 ℃。系統性能如表1所示,1月7日和10日夜間未進行放熱,水溫保持在20.7和19.1 ℃,在白天系統僅集熱1.3~1.8 h,集熱量分別為12.6和4.2 MJ,其余3 d均進行了長時間的集熱,集熱時長為5.8~7.3 h,集熱量達到了390.6~693 MJ,平均集熱流量為18.7~27.1 kW;夜間放熱時長為3.3~8.6 h,放熱量為361.2~609 MJ,平均放熱流量為20.8~31.5 kW;系統COP達到了4.4~7.2。

表1 系統性能參數

系統集放熱性能主要被水氣溫差、風速以及水流量影響,采用系統的集放熱流量來評價系統集放熱性能,熱流量越大,則單位時間里系統換熱量越大[26],試驗期間風速和水流量基本保持恒定,因此水氣溫差成為影響系統集放熱性能的關鍵因素。棚內逐時集熱流量和放熱流量如圖3a、3b所示,熱流量與水氣溫差呈正向線性相關,即水氣溫差越大,熱流量越大。放熱階段水氣溫差在5.9~18 ℃時,放熱流量為3.4~9.83 kW,擬合結果如圖3b所示,20.991 9,相關性較高,水氣溫差每增長1 ℃,放熱流量增加0.58 kW,當水氣溫差降至0時,系統不再放熱;集熱階段熱流量與水氣溫差變化關系的擬合結果如圖3a所示,20.894 1,集熱階段水氣溫差在1.6~12 ℃之間時,集熱流量為0~8.53 kW,根據擬合關系方程水氣溫差每增長1 ℃,集熱流量增加0.82 kW,在水氣溫差為2.9 ℃時,系統集熱流量為零,而系統運行條件中設定水氣溫差小于2 ℃,在這段氣溫變化時間內,表冷器-風機集放熱系統處于做無用功狀態,耗電量增加,從而降低了系統COP,需要調整集熱階段的關閉條件以提高系統COP。

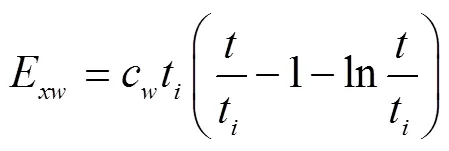

集熱階段熱流量與水氣溫差擬合關系方程相關性較放熱階段低,是由于在集熱階段存在空氣中水蒸氣遇冷凝結的相變過程,系統并非全程是在干工況下運行。在除濕冷卻過程中,冷凝水析出程度可由析濕系數反映,析濕系數可按照下式計算[31]:

式中為析濕系數;,h分別為表冷器-風機進口空氣、出口空氣的焓,kJ/kg;,t分別為表冷器-風機進口空氣、出口空氣溫度,℃。

試驗中空氣定壓比熱c取恒值1.003 kJ/(kg·℃),結合公式(11)可知表冷器-風機進出口空氣溫差和焓差呈線性相關,在干工況下析濕系數為1。表冷器-風機進出口空氣溫差和焓差關系的擬合結果如圖3c所示,其斜率可認為是系統集熱階段表冷器-風機析濕系數的數值,即析濕系數為1.70,表明表冷器-風機集放熱系統在集熱階段是濕工況運行,具有一定的冷凝除濕效果。

2.3 系統的除濕效果

表冷器-風機集放熱系統具有一定的除濕效果,尤其是在白天集熱階段。含濕量和相對濕度均是用來表征空氣中水蒸氣含量的物理量,相對濕度表示了空氣接近飽和的程度,而含濕量表示了空氣中水蒸氣的含量[33],空氣除濕過程中降低了含濕量,因此可以根據焓濕圖來確定表冷器-風機進出口空氣的含濕量,再通過比較含濕量來分析表冷器-風機冷凝除濕的效果,圖4為1月9日、1月10日和1月12日白天集熱階段表冷器-風機進出口空氣含濕量的變化情況。以1月9日白天集熱階段為例,如圖4a所示,上午9:00系統剛開始集熱時,由于進口水溫遠低于棚內空氣露點溫度,析出了大量的冷凝水,表冷器-風機進出口空氣含濕量差達到了1.2×10-3kg/kg,隨著集熱的進行,水溫升高逐漸逼近棚內空氣露點,在10:00左右冷凝水停止析出,此時含濕量差為0.3×10-3kg/kg。太陽輻射逐漸強烈后,棚內植物的蒸騰作用加劇,空氣中的含濕量迅速上升并在10:40達到了峰值13.8×10-3kg/kg,表冷器-風機進出口空氣含濕量差達到了1.3×10-3kg/kg,在10:40打開通風口后棚內空氣含濕量陡降,冷凝除濕效果也大幅下降,并逐漸保持在一定范圍內小幅波動;關閉通風口后棚內濕度開始增加,經過長時間集熱水溫已經超過棚內空氣的露點溫度,進出口空氣含濕量相等,此時集熱階段空氣中水蒸氣不發生冷凝相變。1月10日和1月12日白天集熱階段表冷器-風機進出口空氣含濕量也表現出了相似的變化趨勢。

2.4 系統的除濕性能分析

3 討 論

本文表冷器-風機集放熱系統中表冷器-風機成本約為0.8 萬元,蓄熱水箱成本約為1.0萬元,循環水泵、供回水管路及控制系統成本約為0.4萬元,合計建造成本約2.2萬元。試驗期間系統運行總耗電量130.6 kW·h,根據溫州當地農業用電價格0.7280元/kW·h,該系統在試驗期間的運行成本共95.1元;總放熱量為2146.2 MJ,折算為天然氣[25]需消耗57.1 m3,按當地非居民用戶天然氣價格3.12元/m3,折合天然氣供暖成本為178.2元,由此可見表冷器-風機集放熱系統雖需一定的前期建造成本,但運行成本大幅度降低。

本試驗中系統參數僅按照試驗連棟塑料大棚南側跨體積進行配置,北側跨則作為對照組不設置加溫裝置,但由于試驗期間遭遇寒潮,為使作物免遭凍害絕產,表冷器-風機集放熱系統同時為南北側跨進行加溫,在這種超負荷運行的情況下,系統配合二道膜保溫仍然能讓棚內氣溫保持在一定的水平,僅在兩側棚頭位置由于冷風滲透而引起的小部分作物凍害,因此表冷器-風機集放熱系統還具有較大的集放熱潛力。另外相較于日光溫室,連棟塑料大棚的保溫性能較差,在加溫過程中會有大量的熱損失[33-34],熱負荷較大,因此在本文試驗條件下還無法應對白天陰天(即白天棚內氣溫較低,系統集熱時間短或不集熱)且夜間寒冷的極端天氣,同時未對表冷器-風機集放熱系統供暖的均勻性進行考慮,如何減小供暖的不均勻性在之后的研究中也需要深入探索。

總的來說表冷器-風機集放熱系統使夜間棚內氣溫較棚外高5.2~7.8 ℃,保護棚內作物免遭凍害,并且系統的能量來源于空氣余熱,屬于一種清潔能源,且控制靈活、成本低、不占用棚內空間,可以作為南方連棟塑料大棚中應對寒潮侵襲的有效加溫措施,在生產實際中,增設保溫性良好的保溫幕布等提高連棟塑料大棚的保溫性能,是一種輔助表冷器-風機集放熱系統應對連陰天的解決方案[27]。

表冷器-風機集放熱系統具有一定的除濕效果,在前人研究中也有提及[24],尤其是在集熱階段初期的冷凝除濕過程,在本研究中,冷凝除濕過程會隨著集熱時間的延長而逐漸消失,這是因為進入表冷器-風機的水溫逐漸升高而逼近或超過棚內空氣露點溫度,因此尋找一個穩定的冷源來提供恒溫的冷水,是可以在表冷器-風機集放熱系統的基礎上開發出一種表冷器-風機冷凝除濕系統,怎樣低耗、高效地制備恒溫的冷水以及冷凝除濕對棚內氣溫水平的影響也將在后續的試驗中進行。

4 結 論

1)在寒潮下,表冷器-風機集放熱系統可以使夜間棚內氣溫較棚外高5.2~7.8 ℃,保護棚內作物免遭寒潮等氣溫驟降的不利天氣引起的凍害。

2)白天集熱量達到了390.6~693 MJ,夜間放熱量為361.2~609 MJ,系統性能系數(COP)達到了4.4~7.2,因此表冷器-風機集放熱系統具有良好的加溫效果和節能性,但是受連棟塑料大棚保溫性能較差的影響,熱損較大。在本試驗條件下,集熱階段在水氣溫差低于2.9 ℃時,系統處于做無用功狀態,可適當調整系統設定條件,如集熱階段水氣溫差小于3 ℃時關閉系統,縮短系統運行時間,提高COP。

3)表冷器-風機集放熱系統在集熱階段具有一定的除濕效果,表冷器-風機進出口空氣含濕量差最高可達1.3×10-3kg/kg,但隨著水溫的升高,除濕效果會減弱至消失。

[1] 國家氣象中心. 冷空氣等級:GB/T 20484-2017[S]. 北京:中國國家標準化管理委員會,2017.

[2] 王克磊,朱隆靜,蘇世聞,等. 新型大跨度單體塑料大棚溫光性能分析[J]. 中國農機化學報,2021,42(2):45-50.

Wang Kelei, Zhu Longjing, Su Shiwen, et al. Analysis of temperature and light characteristics of new large span single plastic greenhouse[J]. Journal of Chinese Agricultural Mechanization, 2021, 42(2): 45-50. (in Chinese with English abstract)

[3] 朱隆靜,王克磊,陳先知,等. 浙南單體塑料大棚內冬季溫光性能特征研究[J]. 農學學報,2020,10(6):81-85.

Zhu Longjing, Wang Kelei, Chen Xianzhi, et al. The characteristics of temperature and light properties of single plastic greenhouse in winter of southern Zhejiang[J]. Journal of Agriculture, 2020, 10(6): 81-85. (in Chinese with English abstract)

[4] 楊再強,朱凱,趙翔,等. 中國南方塑料大棚氣象災害風險區劃[J]. 自然災害學報,2012,21(5):213-221.

Yang Zaiqiang, Zhu Kai, Zhao Xiang, et al.Meteorological disaster risk zoning for plastic greenhouse in south China[J]. Journal of Natural Disasters, 2012, 21(5): 213-221. (in Chinese with English abstract)

[5] 魏莎莎,李清斌,孫軍波,等. 強寒潮天氣南方塑料大棚防御冰凍災害措施[J]. 中國農學通報,2017,33(29):135-139.

Wei Shasha, Li Qingbin, Sun Junbo, et al. Preventing frozen disaster in plastic greenhouse in South China[J]. Chinese Agricultural Science Bulletin, 2017, 33(29):135-139. (in Chinese with English abstract)

[6] 鮑恩財,曹晏飛,鄒志榮,等. 節能日光溫室蓄熱技術研究進展[J]. 農業工程學報,2018,34(6):1-14.

Bao Encai, Cao Yanfei, Zou Zhirong, et al. Research progress of thermal storage technology in energy-saving solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(6): 1-14. (in Chinese with English abstract)

[7] Attar I, Naili N, Khalifa N, et al. Parametric and numerical study of a solar system for heating a greenhouse equipped with a buried exchanger[J]. Energy Conversion and Management, 2013, 70: 163-173.

[8] Attar I, Farhat A. Efficiency evaluation of a solar water heating system applied to the greenhouse climate[J]. Solar Energy, 2015, 119: 212-224.

[9] 張義,楊其長,方慧. 日光溫室水幕簾蓄放熱系統增溫效應試驗研究[J]. 農業工程學報,2012,28(4):188-193.

Zhang Yi, Yang Qichang, Fang Hui. Research on warming effect of water curtain system in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(4): 188-193. (in Chinese with English abstract)

[10] Xu Weiwei, Song Weitang, Ma Chengwei. Performance of a water-circulating solar heat collection and release system for greenhouse heating using an indoor collector constructed of hollow polycarbonate sheets[J]. Journal of Cleaner Production, 2020, 253: 119918.

[11] 徐微微,馬承偉,宋衛堂,等. 日光溫室中空板水循環集放熱系統設計與集熱性能試驗[J]. 農業機械學報,2018,49(7):326-334.

Xu Weiwei, Ma Chengwei, Song Weitang, et al. Test on heat-collecting performance of solar heat collection and release system with water cycling inside hollow plates in Chinese solar greenhouse[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 326-334. (in Chinese with English abstract)

[12] 馬承偉,姜宜琛,程杰宇,等. 日光溫室鋼管屋架管網水循環集放熱系統的性能分析與試驗[J]. 農業工程學報,2016,32(21):209-216.

Ma Chengwei, Jiang Yichen, Cheng Jieyu, et al. Analysis and experiment of performance on water circulation system of steel pipe network formed by roof truss for heat collection and release in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 209-216. (in Chinese with English abstract)

[13] Santamouris M, Mihalakakou G, Balaras C A, et al. Energy conservation in greenhouses with buried pipes[J]. Energy, 1996, 21(5): 353-360.

[14] 張勇,高文波,鄒志榮. 日光溫室主動蓄熱后墻傳熱CFD模擬及性能試驗[J]. 農業工程學報,2015,31(5):203-211.

Zhang Yong, Gao Wenbo, Zou Zhirong. Performance experiment and CFD simulation of heat exchange in solar greenhouse with active thermal storage back-wall[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(5): 203-211. (in Chinese with English abstract)

[15] 趙淑梅,莊云飛,鄭可欣,等. 日光溫室空氣對流蓄熱中空墻體熱性能試驗[J]. 農業工程學報,2018,34(4):223-231.

Zhao Shumei, Zhuang Yunfei, Zheng Kexin, et al. Thermal performance experiment on air convection heat storage wall with cavity in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(4): 223-231. (in Chinese with English abstract)

[16] ?ztürk H H, Ba??etin?elik A. Energy and exergy efficiency of a packed-bed heat storage unit for greenhouse heating[J]. Biosystems Engineering, 2003, 86(2): 231-245.

[17] Gautam A, Saini R P. A review on sensible heat based packed bed solar thermal energy storage system for low temperature applications[J]. Solar Energy, 2020, 207: 937-956.

[18] Chen Shuqin, Zhu Yipan, Chen Yue, et al. Usage strategy of phase change materials in plastic greenhouses, in hot summer and cold winter climate[J]. Applied Energy, 2020, 277: 115416.

[19] 陳淑琴,朱毅攀,謝靜超,等. 相變材料在南方塑料大棚中的冬季使用策略及效果研究[J]. 太陽能學報,2020,41(11):205-211.

Chen Shuqin, Zhu Yipan, Xie Jingchao, et al. Study on winter application strategy and effect of phase change material in southern plastic greenhouse[J]. Acta Energiae Solaris Sinica, 2020, 41(11): 205-211. (in Chinese with English abstract)

[20] 凌浩恕,陳超,陳紫光,等. 日光溫室帶豎向空氣通道的太陽能相變蓄熱墻體體系[J]. 農業機械學報,2015,46(3):336-343.

Ling Haoshu, Chen Chao, Chen Ziguang, et al. Performance of phase change material wall with vertical air channels integrating solar concentrators[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(3): 336-343. (in Chinese with English abstract)

[21] Yang S, Rhee J. Utilization and performance evaluation of a surplus air heat pump system for greenhouse cooling and heating[J]. Applied Energy, 2013, 105: 244-251.

[22] Chai L L, Ma C W, Ni J Q. Performance evaluation of ground source heat pump system for greenhouse heating in northern China[J]. Biosystems Engineering, 2012, 111(1): 107-117.

[23] 王志偉,楊佳佳,劉義飛,等. 南疆日光溫室表冷器主動蓄放熱系統設計與應用效果[J]. 北方園藝,2019(12):47-54.

Wang Zhiwei, Yang Jiajia, Liu Yifei, et al. Research on the design and application effect of active extracorporeal heat storage system for solar greenhouse surface air cooler in southern Xinjiang[J]. Northern Horticulture, 2019(12): 47-54. (in Chinese with English abstract)

[24] 孫維拓,郭文忠,徐凡,等. 日光溫室空氣余熱熱泵加溫系統應用效果[J]. 農業工程學報,2015,31(17):235-243.

Sun Weituo, Guo Wenzhong, Xu Fan, et al. Application effect of surplus air heat pump heating system in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(17): 235-243. (in Chinese with English abstract)

[25] 李明,耿若,宋衛堂,等. 外保溫塑料大棚表冷器-風機集放熱系統性能分析[J]. 農業機械學報,2020,51(10):371-378.

Li Ming, Geng Ruo, Song Weitang, et al. Performances of thermal collecting and releasing system developed with fan-coil units in plastic tunnel covered with thermal blanket[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(10): 371-378. (in Chinese with English abstract)

[26] 何雪穎,王平智,李明,等. 基于響應面法的表冷器-風機集放熱系統參數優化[J]. 農業機械學報,2020,51(12):315-323.

He Xueying, Wang Pingzhi, Li Ming, et al. Parameters optimization of greenhouse air-cooled condenser heat collection and release system by response surface method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(12): 315-323. (in Chinese with English abstract)

[27] 宋衛堂,王平智,肖自斌,等. 表冷器-風機集放熱系統對四種園藝設施室內氣溫的調控效果研究[J]. 農業工程技術,2020,40(4):38-48.

[28] 李世姣,王令. 高溫冷水表冷器除濕系統的?分析[J]. 制冷與空調,2016,30(4):436-440.

Li Shijiao, Wang Ling. Exergy analysis of cooling coil with higher temperature of cold water[J]. Refrigeration and Air Conditioning, 2016, 30(4): 436-440. (in Chinese with English abstract)

Luan Zhiyong. Analysis of condensing heat recovery exergy for central Heating[J]. Energy and Energy Conservation, 2013(9): 18-21. (in Chinese with English abstract)

[30] 呂艷. 熱濕獨立處理空調系統的能耗模擬與實驗研究[D]. 鎮江:江蘇科技大學,2010.

[31] 樂有奮,王清平. 表冷器熱工計算新方法——水側熱交換效率法[J]. 暖通空調,2005(7):122-126.

Le Youfen, Wang Qingping. New thermodynamic calculation method for surface air coolers: heat-exchange efficiency of waterside method[J]. Heating Ventilating & Air Conditioning, 2005(7): 122-126. (in Chinese with English abstract)

[32] 田向寧,楊毅,丁德,等. 空氣冷卻除濕過程的理論研究[J]. 暖通空調,2014(1):121-124.

Tian Xiangning, Yang Yi, Ding De, et al. Theoretical research on air cooling dehumidification process[J]. Heating Ventilating & Air Conditioning, 2014(1): 121-124. (in Chinese with English abstract)

[33] Kim H, Kang G, Moon J P, et al. Estimation of thermal performance and heat loss in plastic greenhouses with and without thermal curtains[J]. Energies, 2018, 11(3): 578.

[34] Teitel M, Barak M, Antler A. Effect of cyclic heating and a thermal screen on the nocturnal heat loss and microclimate of a greenhouse[J]. Biosystems Engineering, 2009, 102(2): 162-170.

Influences of air thermal energy utilization system with fan-coil units on the thermal and humid environment of multi-span tunnel in cold wave

Zong Chengji1, Wang Pingzhi1,2, Chen Xianzhi3, Li Ming1,2, He Xueying1,Wang Jianyu1, Xu Dan1,2, Song Weitang1,2※

(1.100083; 2.100083;3.325000)

Multi-span plastic tunnel greenhouse has widely been used in the cultivation of vegetables, fruits, and flowers. However, it is easily suffered from freezing damage to crops, particularly from cold waves in winter. In this study, an air thermal energy utilization system was developed with the fan-coil units to effectively control the thermal and humid environment in the shed. A field experimented was also performed on a two-span plastic tunnel in Wenzhou city of China during the cold wave from January 8 to January 13, 2021. The system was composed of fan-coil units, water reservoir, circulating water pump, supply and return water pipes, as well as control devices. The circulation of water in the system was utilized to collect and then store the surplus heat in the shed during the day, while finally released at night to heating the two-span plastic tunnel. In the collected phase, once the air temperature in the shed reached 15 ℃ on the day, or it was 5 ℃ higher than the water temperature in the water reservoir, the system was started until the air temperature dropped to 10 ℃, or it was 2 ℃ lower than the water temperature. In the released phase, once the outside air temperature was below 2 ℃ at night, or it was 4 ℃ lower than the water temperature, the system was started to operate until the air temperature reached 5 ℃, or it was only 2 ℃ higher than the water temperature. The collected and released performance of the system was evaluated using the collection and discharge heat, as well as heat flow, according to the change of water temperature in the experiment. The difference between water and air temperature was taken as the main influencing factor to analyze the heat flow in the collected and released phases. An exergy analysis of condensation dehumidification was also made during this time. The results showed that the system ensured the temperature inside the shed was 5.2-7.8 ℃ to protect crops from freezing damage, higher than that outside the shed in cold waves. The heat collection was 390.6-693 MJ, while the heat release was 361.2-609 MJ. The Coefficient of Performance (COP) of the system was 4.4-7.2, indicating quite remarkable energy saving. When the difference in water temperature increased by 1 ℃ during the operation of the system, the heat collection flow rate increased by 0.82 kW, while the heat release flow rate increased by 0.58 kW, indicating a larger heat transfer rate per unit time. In addition, the moisture absorption coefficient of the system was about 1.70 in the heat collected phase, due mainly to the presence of condensation and dehumidification. Meanwhile, the exergy efficiency tended to increase rapidly, up to 82.8%, as the temperature difference between water and air increased, indicating high energy utilization performance in the process of condensation and dehumidification. Nevertheless, the condensation and dehumidification gradually weakened until stopped, and concurrently the exergy efficiency decreased significantly, with the increase of water temperature. Consequently, the air thermal energy utilization system with fan-coil units can be expected to serve a safe, low carbon, and controllable heating technology. The finding can provide a potential application to ensure the safe production of multi-span plastic tunnels in winter.

facility; temperature; multi-span plastic tunnel; fan-coil units; thermal and humid environment; heating; dehumidify

10.11975/j.issn.1002-6819.2021.15.026

S625.2; S625.4

A

1002-6819(2021)-15-0214-08

宗成驥,王平智,陳先知,等. 寒潮天氣表冷器-風機集放熱系統對連棟大棚熱濕環境的影響[J]. 農業工程學報,2021,37(15):214-221.doi:10.11975/j.issn.1002-6819.2021.15.026 http://www.tcsae.org

Zong Chengji, Wang Pingzhi, Chen Xianzhi, et al. Influences of air thermal energy utilization system with fan-coil units on the thermal and humid environment of multi-span tunnel in cold wave[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(15): 214-221. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.15.026 http://www.tcsae.org

2021-06-21

2021-07-29

國家重點研發計劃項目(2020YFD1000300);浙江省科技計劃項目(2019C02009);現代農業產業技術體系建設專項資金項目(CARS-23-C02)

宗成驥,博士生,研究方向為設施園藝環境工程。Email:Zongchanging@163.com。

宋衛堂,教授,研究方向為園藝設施環控技術和裝備研發。Email:songchali@cau.edu.cn。

中國農業工程學會會員:宋衛堂(E040100004M)