田間作業條件下摘錠耐磨性能及棉花采凈率的試驗研究

李海洋,王玉剛,傅秀清,張宏文,王 磊,王 蒙,杜欣田,魏喜梅,扶學文,韓秉東

田間作業條件下摘錠耐磨性能及棉花采凈率的試驗研究

李海洋1,2,王玉剛3,傅秀清4,張宏文1,2※,王 磊1,2,王 蒙1,2,杜欣田1,2,魏喜梅1,2,扶學文1,2,韓秉東1,2

(1. 石河子大學機械電氣工程學院,石河子 832003; 2. 農業農村部西北農業裝備重點實驗室,石河子 832003;3.山東天鵝棉業機械股份有限公司,濟南 250032; 4.南京農業大學工學院,南京 210031)

為了探究田間作業條件下摘錠的耐磨性能與棉花采凈率,該研究將未鈍化摘錠和鈍化摘錠安裝到采棉機不同采摘頭上,在作業面積達到0、150、300、450、600 hm2時,獲取2種摘錠樣本并進行切割制樣,分析鉤齒磨損形貌,提取鉤齒磨損面積及鍍層厚度,同時測定2種摘錠的采凈率。結果表明:未鈍化摘錠的鉤齒前齒尖易折斷,鈍化摘錠的鉤齒鍍層剝落晚于未鈍化摘錠。在相同作業面積下,鈍化摘錠的鉤齒磨損面積更小,在測試位置的鍍層厚度更高;當作業面積達到600 hm2時,未鈍化摘錠的鉤齒平均磨損面積達到2.9×105μm2,約為鈍化摘錠的2.6倍;未鈍化摘錠1號、2號鉤齒及鈍化摘錠1號鉤齒測試位置鍍層剝落,鈍化摘錠具有更加優異的耐磨性能。對照2種全新摘錠的采凈率,鈍化摘錠的采凈率比未鈍化摘錠低0.2個百分點;當作業面積達到約200 hm2時,2種摘錠的采凈率相差不大;當作業面積超過200 hm2時,鈍化摘錠的采凈率大于未鈍化摘錠;當作業面積為450 hm2時,未鈍化摘錠和鈍化摘錠采凈率均達到最大值,分別約為96.4 %和96.7 %;當作業面積為600 hm2時,鈍化摘錠的采凈比未鈍化摘錠高0.5個百分點,鈍化摘錠具有更加優異的采摘性能。該研究成果對于采棉機摘錠鉤齒的結構優化與修形具有重要意義。

農業機械;棉花;摘錠;鈍化;耐磨性能;磨損形貌;采凈率

0 引 言

棉花原產于亞熱帶地區,品種繁多[1-3],是重要的經濟作物[4-6],在國防、醫藥和工業中發揮著重要作用[7-8]。中國新疆適宜的環境和氣候為棉花的生長、吐絮提供了條件[9-10],已經成為國內棉花的主要生產區域[11]。棉花機械化采收是促進棉花種植規模迅猛發展的主要原因之一,更是各項先進技術在棉花生產中應用的體現[12-14]。由于棉花的機械化采收效率高、成本低[15],采棉機在中國新疆等主要棉花種植地區得到廣泛的運用[16]。

摘錠是采棉機的關鍵核心部件[17-20];鉤齒是摘錠鉤掛棉花的關鍵結構,易磨損[21-23]。摘錠對棉花的鉤掛能力依賴于鉤齒的完整性,鉤齒磨損將直接影響機采棉的采收質量和采凈率[24-27]。WANG等通過臺架試驗分析了不同鉤齒角度參數對摘錠采摘性能的影響[28]。隨著研究人員對摘錠磨損失效過程的研究,發現其磨損失效是多種磨損形式協同作用的結果[29-33]。GU等在田間作業條件下,獲取摘錠樣本并對其表面形貌進行了表征,結果表明,摘錠鉤齒鍍層的磨損主要是由磨粒磨損和疲勞剝落造成的,基體的磨損是磨粒磨損和氧化磨損共同作用的結果[34-35]。LI等對摘錠的12個鉤齒進行了切割制樣并利用掃描電子顯微鏡表征了其表面形貌,結果表明鉤齒的磨損從前齒尖、后齒尖開始出現,并向齒刃與齒背面延伸,再向脫棉刃延伸,形成長筒靴狀的磨損區域[16]。為提高摘錠的耐磨性能,GLENN等對其進行薄陶瓷涂層處理,以提高其光滑度和硬度[36]。張有強等提出對摘錠表面進行電磁處理,降低其殘余應力,以提高其抗磨損能力[22]。AMANOV等利用超聲波誘導摘錠表面出現嚴重的塑形變形,以改善材料表面完整性、增加其機械性能,提高其耐磨性[37]。張宏文等設計了一種具有仿形結構鉤齒的采棉機摘錠,通過設置仿形結構預磨面實現摘錠鉤齒齒刃與棉稈的線接觸向面接觸轉變,能夠提升鉤齒齒刃部位鍍層壽命,從而有效提高摘錠的耐磨性能[38]。上述幾種方案雖然能提升摘錠的耐磨性能,但忽略了加工的難易程度與加工成本。前期調研過程中發現摘錠在作業過程中其鉤齒齒尖和齒刃部位易先出現磨損,導致其耐磨性能較差。為了解決這種問題,研究人員在摘錠電鍍之前利用電解的方法對摘錠鉤齒的齒尖和齒刃部位進行鈍化,以提升摘錠的耐磨性能[39]。

為了探究鈍化摘錠的耐磨性能和采摘性能,本研究設計加工了未鈍化摘錠和鈍化摘錠,并將2種摘錠分別安裝在采棉機的不同采摘頭上。在采棉機達到不同作業面積時,從采摘頭前滾筒座管上獲取摘錠樣本,并對其進行切割制樣,分析2種摘錠鉤齒的磨損形貌,提取鉤齒磨損面積,測量鉤齒鍍層厚度,并測定2種摘錠的采凈率,對比分析鈍化摘錠的耐磨性能和采摘性能。

1 材料與方法

1.1 試驗摘錠

摘錠主要由傳動部分、支撐部分和采摘部分組成,其中采摘部分設置有3列鉤齒,每列鉤齒的數量為12個。本研究試驗采用2種摘錠,一種為鉤齒未經過鈍化處理(表述為未鈍化摘錠,鉤齒截面齒刃處的曲率半徑約為0.025~0.036 mm),另一種為鉤齒經過鈍化處理(本文表述為鈍化摘錠,鉤齒截面齒刃處的曲率半徑約為0.045~0.060 mm),2種摘錠均與合作企業共同開發研制,基體材料均為20CrMnTi,基體表面均進行滲碳處理,鍍層材料均為Cr。摘錠總體結構與鉤齒截面顯微形貌如圖1所示。

1.2 試驗設備

試驗所用設備包括:John Deere采棉機(型號:CP690,配備Pro-16采摘頭),數控電火花線切割機床(型號:DK-7732,電極絲直徑:0.18 mm,加工精度:0.01 mm,用于切割摘錠鉤齒),超聲波清洗器(型號:DL-720D,用于清洗摘錠表面污漬),激光共聚焦顯微鏡(型號:LEXT-4100,高度分辨率:10 nm,用于觀察摘錠截面形貌并測量鉤齒鍍層厚度),金相試樣鑲嵌機(型號:XQ-1,試樣規格:30 mm,用于鉤齒截面樣本的鑲嵌),金相磨拋機(型號:ZMP-2000,用于鉤齒截面樣本的研磨拋光),掃描電子顯微鏡(型號:S-4800,加速電壓:0.5~30 kV,放大倍數:30~800 000倍,用于鉤齒磨損形貌的表征),電子稱(型號:SB-3003,精度:0.001 g,用于采凈率測試過程中籽棉樣本的稱量)。

1.3 試驗方法

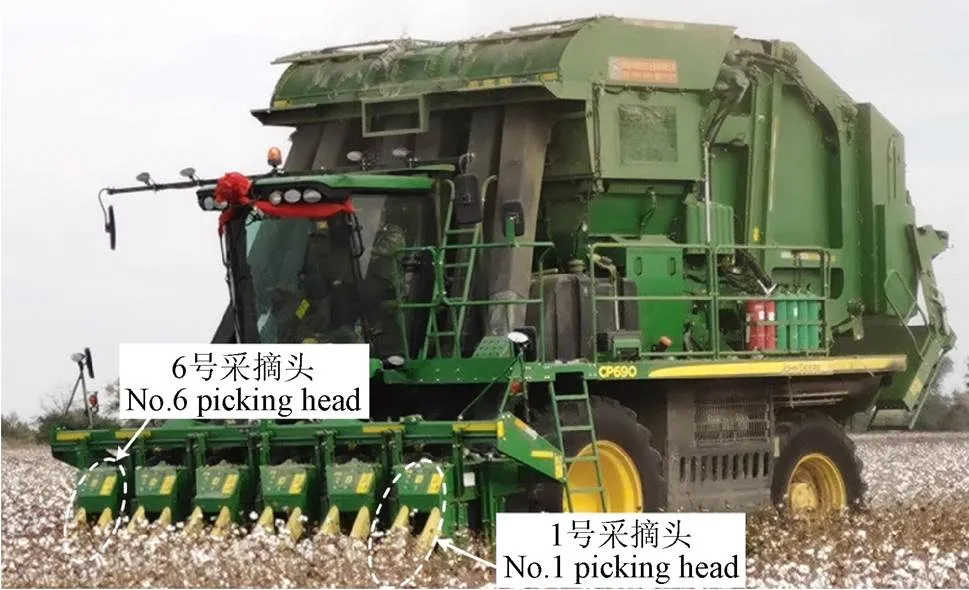

試驗于2021年10月8日至11月3日在新疆奎屯市進行。以摘錠種類和摘錠作業面積為試驗因素,以鉤齒磨損形貌、磨損面積、鍍層厚度及采凈率為評價指標,探究摘錠的耐磨性能與采摘性能。試驗前將2種摘錠分別安裝在采棉機1號采摘頭和6號采摘頭上(如圖2所示)。新疆地區一臺CP690采棉機在一個采收季節的作業面積為600~700 hm2,摘錠在田間作業150 hm2左右時,會出現齒尖鍍層的脫落,出現初期的磨損;隨著作業面積的增加,磨損程度逐漸增大[16]。因此,本研究在采棉機作業面積達到0、150、300、450、600 hm2時分別進行采凈率的測定,并獲取2種摘錠樣本。

圖2 CP690采棉機田間采棉試驗

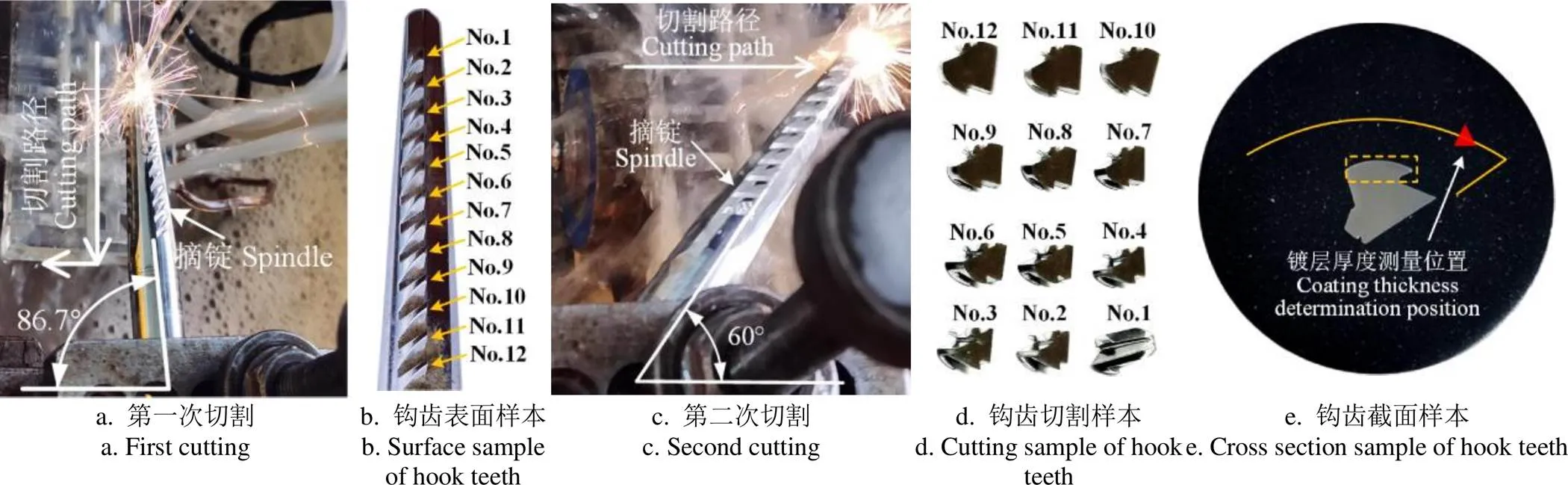

1.3.1 鉤齒的制樣與檢測

每次分別獲取2種摘錠各3根,利用數控電火花線切割機床對摘錠樣本進行第一次切割,摘錠樣本按照如圖3a所示方式夾持,以保證切割路徑與摘錠錐面的母線平行,得到鉤齒表面樣本,并利用超聲波清洗儀清洗其表面污漬,為了便于區分,本文對每列鉤齒進行編號,如圖3b所示。對切割后的剩余部分(包含2列鉤齒)進行第二次切割,摘錠樣本按照如圖3c所示方式夾持,以保證切割路徑與摘錠鉤齒傾斜角度一致,得到1~12號鉤齒的切割樣本,如圖3d所示。利用金相試樣鑲嵌機對切割樣本進行鑲嵌,利用金相磨拋機對鑲嵌樣本進行研磨拋光(所用水砂紙的材質為SiC,型號為800#、1200#和2000#),得到鉤齒截面樣本,如圖3e所示。重復上述操作步驟,完成全部摘錠樣本的切割制樣。由于2種摘錠不同作業面積下的樣本數均為3根,因此2種摘錠在不同作業面積下均有3組鉤齒表面樣本與鉤齒截面樣本。采用掃描電子顯微鏡觀察摘錠鉤齒表面顯微形貌,加速電壓15 kV,放大倍數為50倍。利用CAD軟件提取1~12號鉤齒磨損面積,取3組數據的平均值作為結果。利用激光共聚焦顯微鏡觀察摘錠鉤齒截面形貌并提取鉤齒鍍層厚度,取3組樣本的平均值作為結果。

圖3 鉤齒切割及制樣過程示例

1.3.2 采凈率測定

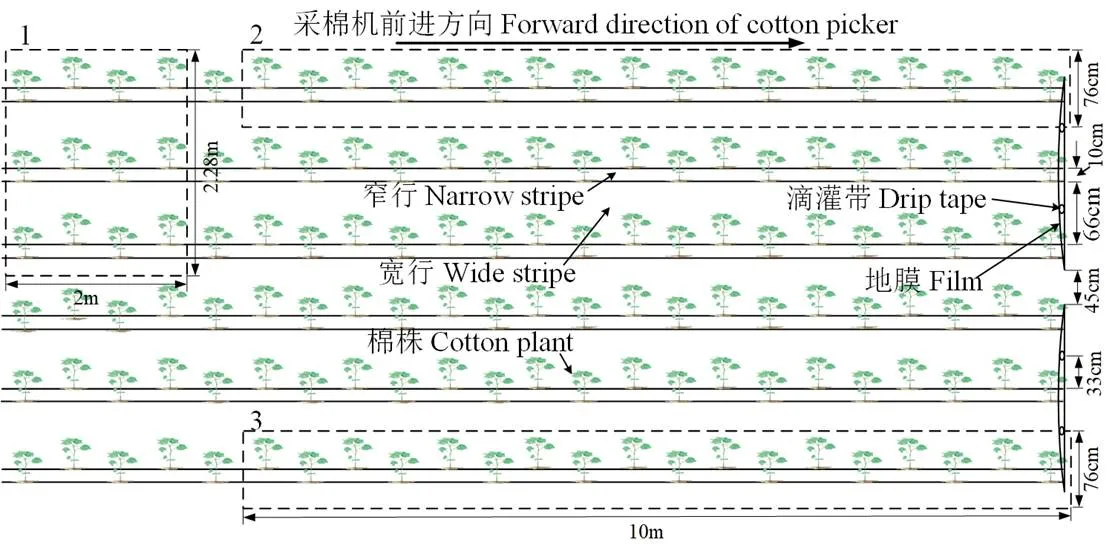

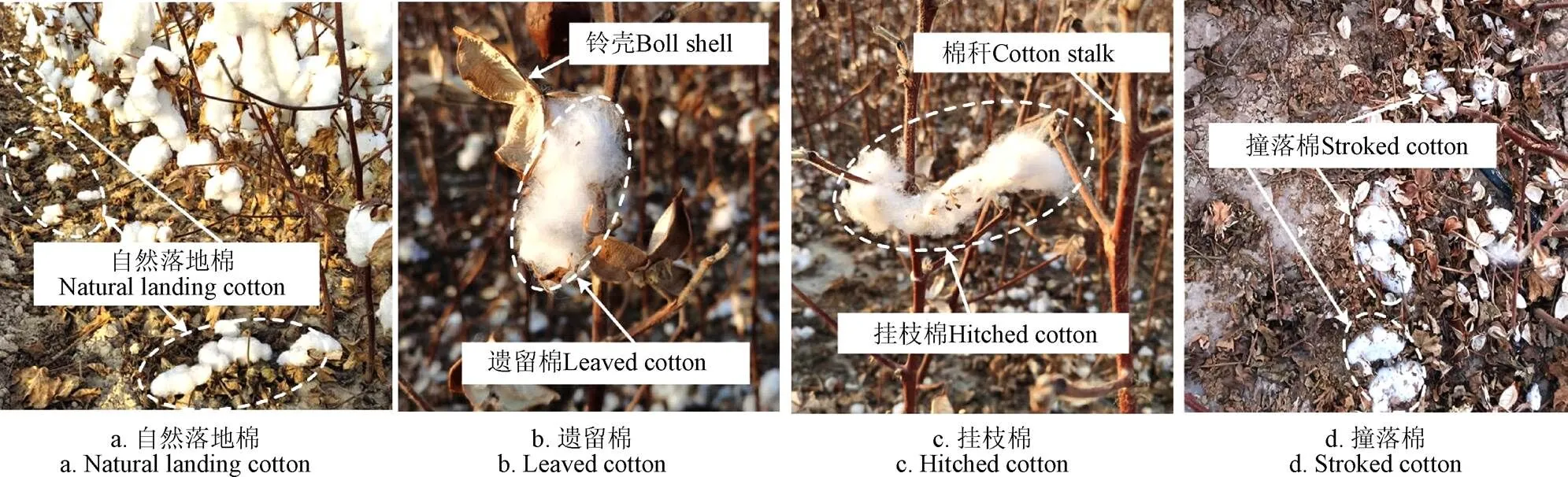

采凈率是衡量摘錠采摘性能的重要指標,摘錠鉤齒的磨損將影響機采棉的采凈率[40-42]。耐磨性能優異的摘錠能夠更長時間地保持鉤齒結構的完整性,保證機采籽棉的采凈率。參照《GB/T 21397 棉花收獲機》對2種摘錠的采凈率進行測定。新疆地區棉花多采用如圖4所示的種植模式[43-44],且地勢平坦,棉田面積大,滿足上述標準中采凈率測定的地表條件。

試驗前先對籽棉產量進行測定,產量測區如圖4中測區1所示。將測區內的籽棉進行人工采收,并對其進行稱量,計算出單位面積籽棉產量(g/m2)。2種摘錠的采凈率測區分別與采棉機1號采摘頭和6號采摘頭的田間作業軌跡重合,如圖4中測區2、3所示。采收前,清理每個測區內的自然落地棉(采摘前自然落到地表的籽棉,如圖5a所示)。采棉機按穩定的作業速度進入測區內進行采摘作業。采收后,收集每個測區內的遺留棉(采收后仍遺留在棉株鈴殼內未被采收的籽棉,如圖5b所示)、掛枝棉(采收后掛在棉株上的籽棉,如圖5c所示)和撞落棉(采收時由于采棉機碰撞而落地的籽棉,如圖5d所示)作為測定樣本。清理籽棉樣本中的雜質并稱量,計算出單位面積遺留棉質量1(g/m2)、單位面積掛枝棉質量2(g/m2)、單位面積撞落棉質量3(g/m2)。在試驗田的四周和中心位置選取5個區域,重復上述操作。

1. 棉花產量測區2. 未鈍化摘錠采凈率測區3. 鈍化摘錠采凈率測區。

圖5 籽棉分類

采凈率是采棉機成功采收的棉花質量與棉田棉花產量的比值。利用式(1)對每次試驗5個測區內2種摘錠的采凈率進行計算,結果取平均值。

式中為采凈率,%。

2 結果與分析

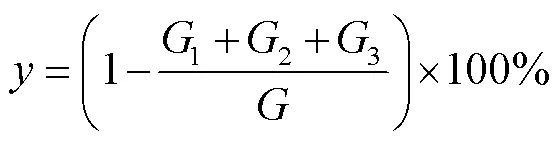

2.1 1號鉤齒磨損形貌

鉤齒磨損形貌是采棉機摘錠耐磨性能最直接的體現,為了評估2種摘錠的耐磨性能,本研究對不同作業面積下摘錠1~12號鉤齒的磨損形貌進行了SEM(掃描電子顯微鏡)分析。其中,1號鉤齒的磨損顯微形貌如圖6所示。

a. 未鈍化摘錠 a. Unpassivated spindleb. 鈍化摘錠 b. Passivated spindle

由圖6可知,新的未鈍化摘錠鉤齒前齒尖較為尖銳,新的鈍化摘錠鉤齒前齒尖和后齒尖存在明顯的鈍化。當作業面積達到150 hm2時,未鈍化摘錠的鉤齒前齒尖折斷,后齒尖鍍層脫落;鈍化摘錠的鉤齒后齒尖進一步鈍化。當作業面積達到300 hm2時,未鈍化摘錠的鉤齒后齒尖的磨損區域擴大,前齒尖同樣出現折斷現象;鈍化摘錠的鉤齒后齒尖鍍層有輕微脫落。隨著作業面積進一步增大,2種摘錠的鉤齒齒刃和齒背均出現了不同程度的磨損。當作業面積達到600 hm2時,未鈍化摘錠的鉤齒鍍層大面積脫落,鈍化摘錠的鉤齒磨損較為輕微。分析認為,采棉作業過程中鉤齒與棉稈、棉花、鈴殼及雜草、沙土、碎石等產生摩擦,鉤齒的磨損最先發生于前、后齒尖與齒刃處,隨著作業面積的增大,鉤齒鍍層厚度逐漸減小,并且伴隨鍍層的疲勞剝落[45-47],基體暴露在空氣中發生氧化磨損,進一步加劇了摘錠的磨損失效[16,34-35]。而鈍化摘錠的鉤齒后齒尖進一步鈍化,是因為鉤齒后齒尖鍍層在作業過程中出現磨損,鍍層厚度減小[35]。未鈍化摘錠的鉤齒前齒尖易折斷現象是因為前齒尖尖銳,應力集中,而鉤齒的鈍化處理能有效降低前齒尖的應力集中[39]。

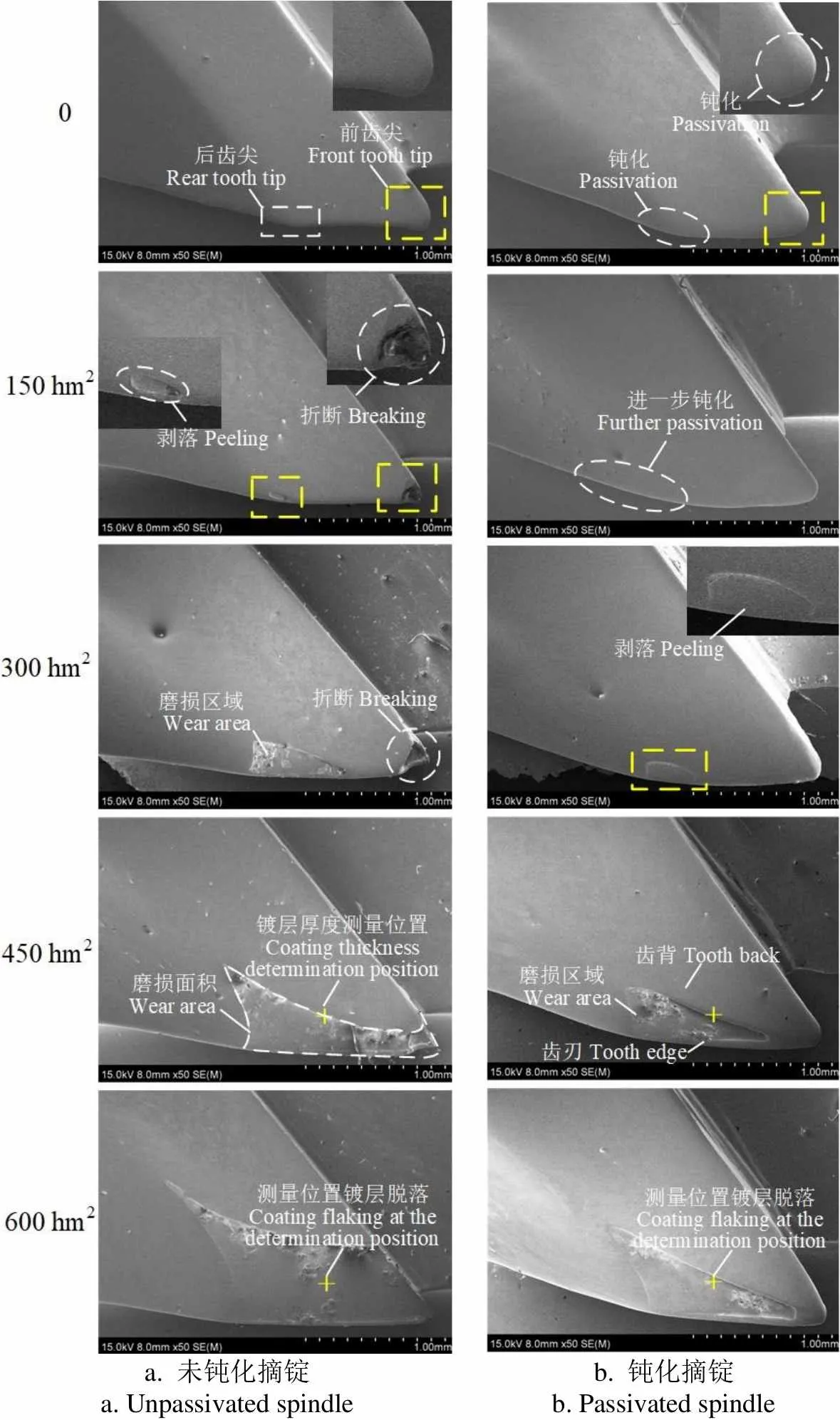

2.2 鉤齒磨損面積

為了更直觀地反應摘錠1~12號鉤齒的磨損失效規律,利用CAD軟件提取不同作業面積下1~12號鉤齒的磨損面積來評估鉤齒的磨損程度。不同作業面積下未鈍化摘錠和鈍化摘錠的鉤齒磨損面積如圖7所示。隨著作業面積增加,2種摘錠的鉤齒磨損面積逐漸增大,并且增大速率增加;未鈍化摘錠的鉤齒磨損面積增大速率大于鈍化摘錠,當作業面積達到600 hm2時,未鈍化摘錠1號鉤齒的磨損面積達到8.8×105μm2,約為鈍化摘錠1號鉤齒磨損面積的2.3倍。在相同的作業面積下,2種摘錠的鉤齒磨損面積均隨鉤齒編號的增大呈下降趨勢,這是因為摘錠對棉花的鉤掛、纏繞主要是通過編號靠前的幾個鉤齒完成的[48-50]。

為了更直觀地對比2種摘錠的耐磨性能,對1~12號鉤齒的磨損面積取平均值,結果如圖7c所示。隨著作業面積的增加,2種摘錠的鉤齒平均磨損面積均呈上升趨勢,且上升速率不斷增大,這與之前的研究結果一致[16,34-35],并且未鈍化摘錠鉤齒平均磨損面積上升的速率更高,在相同作業面積下,鈍化摘錠的鉤齒平均磨損面積更小;當作業面積達到600 hm2時,未鈍化摘錠的鉤齒平均磨損面積達到2.9×105μm2,約為鈍化摘錠的2.6倍。

2.3 鉤齒鍍層厚度

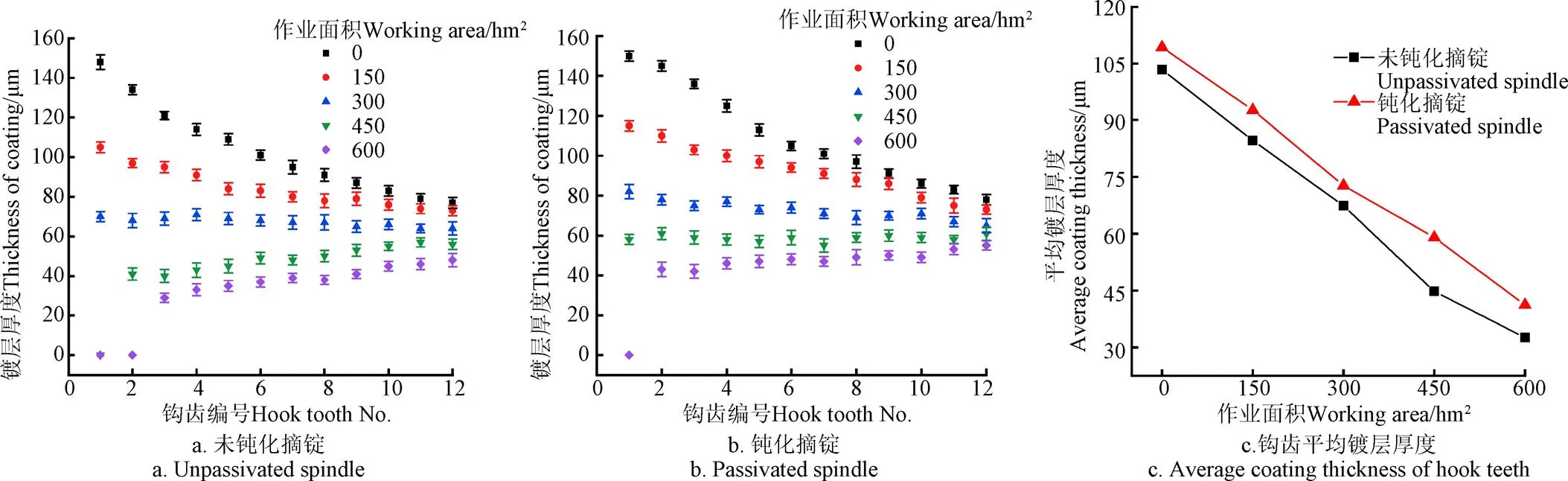

為了探究鉤齒鍍層厚度的變化規律,本研究利用激光共聚焦顯微鏡提取不同作業面積下2種摘錠1~12號鉤齒的鍍層厚度。

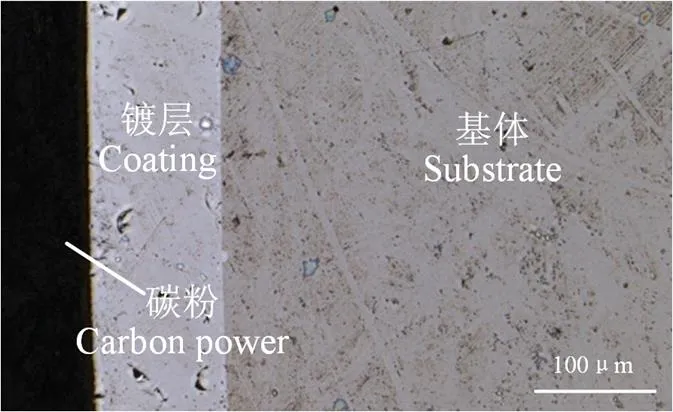

通過對摘錠不同部位鍍層厚度的提取發現,2種全新摘錠各部位鍍層厚度存在差異。以1號鉤齒為例,未鈍化摘錠1號鉤齒前齒尖處鍍層厚度最大,約為150~200 μm,齒刃和后齒尖處鍍層厚度約為140~160 μm;鈍化摘錠1號鉤齒前齒尖、齒刃和后齒尖處的鍍層厚度比未鈍化摘錠小5~20 μm。2種摘錠1號鉤齒齒背在靠近齒刃位置處鍍層厚度較大,遠離齒刃部位鍍層厚度呈遞減趨勢,其變化范圍約為40~160 μm,2~12號鉤齒各部位的鍍層厚度依次降低,激光共聚焦顯微鏡下鉤齒齒背處的截面顯微形貌如圖8所示。分析認為,摘錠電鍍過程中鉤齒前齒尖、齒刃等部位較為尖銳,電荷相對集中,導致鉤齒前齒尖、齒刃等部位鍍層較厚,其余部位鍍層較薄;而摘錠采摘部分前端小后端大,鉤齒編號越小,在電鍍過程中電荷分布越密集,導致1號鉤齒鍍層較厚,2~12號鉤齒各部位鍍層厚度依次降低[16]。隨著作業面積增加,2種摘錠的鉤齒各部位鍍層厚度均逐漸降低。

圖7 摘錠鉤齒磨損面積對比

圖8 鉤齒截面顯微形貌

根據2.1節分析可知,前齒尖、后齒尖和齒刃部位鍍層易脫落,因此,本文對圖3e標記處鍍層厚度進行測量。圖9a、9b為不同作業面積下未鈍化摘錠和鈍化摘錠的鉤齒鍍層厚度。由圖9a、9b可知,對于全新摘錠,鉤齒鍍層厚度隨著鉤齒編號的增大而降低。隨著作業面積的增大,2種摘錠1~12號鉤齒的鍍層厚度均逐漸降低,且降低的速率隨著鉤齒編號的增大而減小,當作業面積達到450、600 hm2時,2種摘錠的鉤齒鍍層厚度均隨鉤齒編號的增大而上升,這是因為摘錠采摘棉花過程主要是通過前幾個鉤齒完成對棉纖維的鉤掛,編號越小的鉤齒鍍層磨損越嚴重[48-50]。在相同的作業面積下,鈍化摘錠的鍍層厚度略大于未鈍化摘錠。當作業面積達到450 hm2時,未鈍化摘錠1號鉤齒測試位置鍍層剝落;當作業面積達到600 hm2時,未鈍化摘錠1號、2號鉤齒測試位置鍍層剝落,鈍化摘錠1號鉤齒測試位置鍍層剝落。

圖9 摘錠鉤齒鍍層厚度對比

為了更直觀地對比2種摘錠的耐磨性能,對1~12號鉤齒的鍍層厚度取平均值,結果如圖9c所示。未鈍化摘錠在測試位置的平均鍍層厚度比鈍化摘錠低5~15 μm,這是因為其鉤齒前齒尖和后齒尖部位較為尖銳,在電鍍過程中電荷較為集中,而測試位置的電荷分布相對較為稀疏,導致齒尖位置鍍層厚度較高而測試位置鍍層厚度較低[16];而鈍化摘錠由于鉤齒的尖銳部位經過鈍化處理,電鍍過程中電荷分布較為均勻,測試位置鍍層厚度略微增大。隨著摘錠作業面積的增加,2種摘錠鉤齒平均鍍層厚度均呈下降趨勢,并且在相同作業面積下,鈍化摘錠的鉤齒平均鍍層厚度更大。從圖9c中也可以看出,作業面積為0~300 hm2時,2種摘錠鉤齒平均鍍層厚度降低的速率幾乎一致;作業面積為300~450 hm2時,未鈍化摘錠鉤齒平均鍍層厚度降低的速率明顯大于鈍化摘錠;作業面積為450~600 hm2時,2種摘錠鉤齒平均鍍層厚度降低的速率相差不大。分析可知,造成該現象的原因為:作業面積為0~300 hm2時,2種摘錠在測試位置的鍍層均未剝落,而2種摘錠鍍層的材質均為Cr,所以2種摘錠鉤齒鍍層厚度降低的速率幾乎一致;作業面積為300~450 hm2時,未鈍化摘錠1號鉤齒測量位置鍍層剝落,會造成該區域的鍍層厚度從約30~50 μm直接降低為0,所以鍍層厚度降低速率較大;作業面積為450~600 hm2時,未鈍化摘錠1號、2號鉤齒以及鈍化摘錠1號鉤齒測試位置鍍層均剝落,所以該階段2種摘錠鉤齒平均鍍層厚度的降低速率相差不大。綜上所述,鈍化摘錠具有更加優異的耐磨性能。

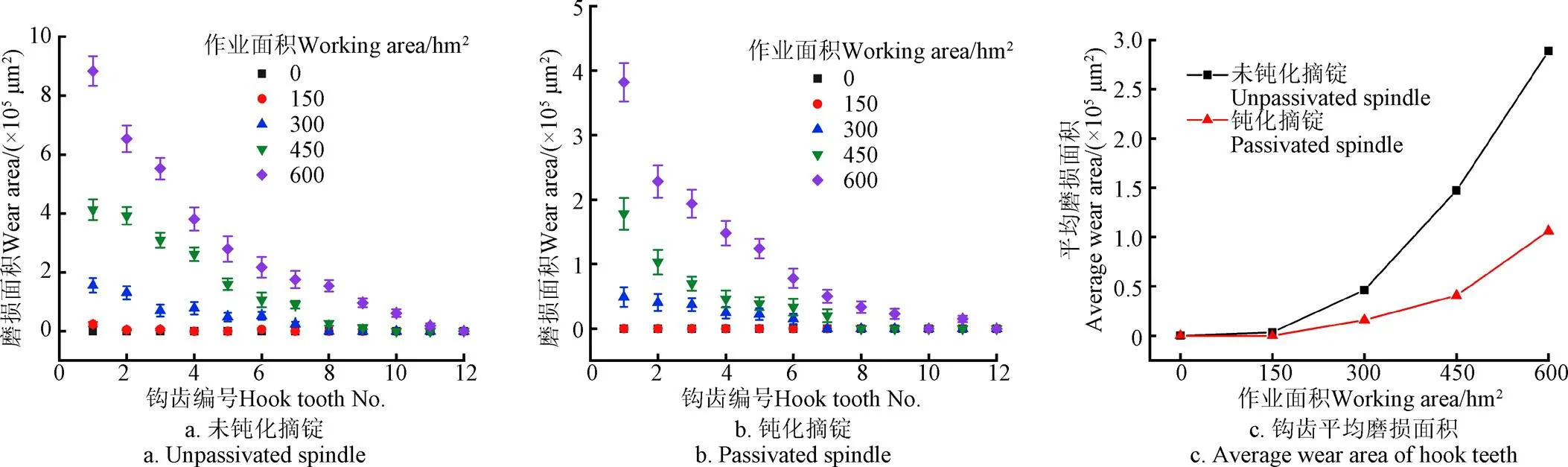

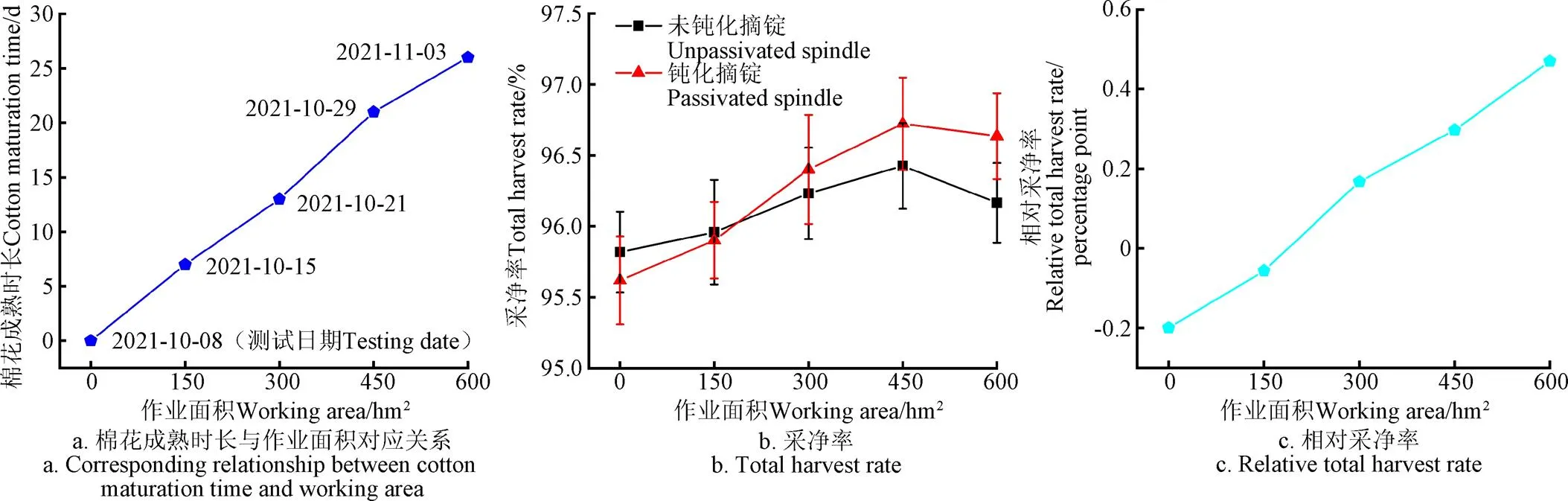

2.4 采凈率

采凈率是體現采棉機采摘性能的重要指標。采棉機在新疆地區一個采收季節的作業時長約為30 d,隨著作業面積的增加,棉花成熟程度不斷提升。以第一次的測試日期(2021年10月8日)為基準對棉花成熟時長進行統計,結果如圖10a所示。圖10b是不同作業階段2種摘錠棉花采凈率的對比。由圖10b可知,作業面積在0~450 hm2時,2種摘錠的采凈率均呈上升趨勢,這是因為隨著作業面積的增加,棉花成熟度上升,棉花與鈴殼之間的生物聯結力降低[51],更容易被采摘;而當作業面積達到450 hm2后,2種摘錠的采凈率呈略微下降趨勢,這是因為此時2種摘錠鉤齒的磨損面積較大,鍍層厚度較小,鉤齒的嚴重磨損導致其對棉花的采摘能力降低。對照2種摘錠的采凈率發現,鈍化摘錠的采凈比未鈍化摘錠低0.2個百分點,這是因為鉤齒的鈍化影響了其對棉花的采摘能力。隨著采棉機作業面積的增加,鈍化摘錠采凈率的上升速率大于未鈍化摘錠,當作業面積達到約為200 hm2時,2種摘錠的采凈相差不大;當作業面積超過200 hm2時,鈍化摘錠的采凈率大于未鈍化摘錠,且2種摘錠的采凈率繼續呈上升趨勢;當作業面積為450 hm2時,未鈍化摘錠和鈍化摘錠的采凈率均達到最大值,分別約為96.4%和96.7%;當作業面積為600 hm2時,鈍化摘錠的采凈比未鈍化摘錠高0.5個百分點。這是因為鈍化摘錠鉤齒鍍層磨損更加緩慢,到后期未鈍化摘錠鉤齒的磨損面積更大、鍍層厚度更低,使得其對棉花的鉤掛能力降低。

為了更直觀地對比2種摘錠的采凈率,將同一作業面積下2種摘錠采凈率的差值記為相對采凈率,其結果如圖10c所示。圖10c反應了隨著作業面積的增加,相對于未鈍化摘錠,鈍化摘錠采凈率呈不斷上升的趨勢。當采棉機作業面積小于200 hm2時,相對采凈率小于0,這是因為此時鈍化摘錠的采凈率小于未鈍化摘錠。隨著作業面積的增加,相對采凈率呈上升趨勢,這是因為在相同的作業面積下鈍化摘錠的磨損程度相對較低,隨著棉花成熟時長的增加,采凈率上升更加迅速。結合圖10b和圖10c可知,鈍化摘錠具有更加優異的采摘性能。

圖10 采凈率對比

3 結 論

1)通過對2種摘錠的鉤齒表面顯微形貌觀察發現,未鈍化摘錠的鉤齒前齒尖易折斷,加快了鉤齒磨損;鈍化摘錠的鉤齒前齒尖和后齒尖存在明顯的鈍化,其鉤齒鍍層的剝落晚于未鈍化摘錠。

2)通過對2種摘錠的鉤齒磨損面積提取發現,未鈍化摘錠的鉤齒磨損面積增大的速率大于鈍化摘錠;在相同作業面積下,鈍化摘錠的鉤齒磨損面積小于未鈍化摘錠,當作業面積達到600 hm2時,未鈍化摘錠的鉤齒平均磨損面積達到2.9×105μm2,約為鈍化摘錠的2.6倍,鈍化摘錠具有更加優異的耐磨性能。

3)通過對2種摘錠的鉤齒鍍層厚度提取發現,隨著作業面積的增大,2種摘錠1~12號鉤齒的鍍層厚度均逐漸降低;在相同的作業面積下,鈍化摘錠的鍍層厚度略大于未鈍化摘錠;當作業面積達到600 hm2時,未鈍化摘錠1號、2號鉤齒測試位置鍍層剝落,鈍化摘錠1號鉤齒測試位置鍍層剝落。

4)對照2種全新摘錠的采凈率發現,鈍化摘錠的采凈比未鈍化摘錠低0.2個百分點;當作業面積達到約200 hm2時,2種摘錠的采凈相差不大;當作業面積超過200 hm2時,鈍化摘錠的采凈率大于未鈍化摘錠;當作業面積為450 hm2時,未鈍化摘錠和鈍化摘錠的采凈率均達到最大值,分別約為96.4%和96.7%;當作業面積為600 hm2時,鈍化摘錠的采凈比未鈍化摘錠高0.5個百分點;鈍化摘錠具有更加優異的采摘性能。

本研究對比分析了田間作業條件下摘錠的耐磨性能和棉花采凈率,對于采棉機摘錠鉤齒的結構優化與修形具有重要意義。

[1] 張龍唱,張宏文,王磊,等. 不同成熟度機采棉采摘力學特性試驗[J]. 甘肅農業大學學報,2020,55(6):193-202. ZHANG Longchang, ZHANG Hongwen, WANG Lei, et al. Study on mechanical characteristics of machine-harvested cotton at different maturity degrees[J]. Journal of Gansu Agricultural University, 2020, 55(6): 193-202. (in Chinese with English abstract)

[2] 盧秀茹,賈肖月,牛佳慧. 中國棉花產業發展現狀及展望[J]. 中國農業科學,2018,51(1):26-36. LU Xiuru, JIA Xiaoyue, NIU Jiahui. The present situation and prospects of cotton industry development in China[J]. Scientia Agricultura Sinica, 2018, 51(1): 26-36. (in Chinese with English abstract)

[3] 喻樹迅. 中國棉花產業百年發展歷程[J]. 農學學報,2018 8(1):85-91. YU Shuxun. The development of cotton production in the recent hundred years of China[J]. Journal of Agriculture, 2018, 8(1): 85-91. (in Chinese with English abstract)

[4] WANG J, Zhang H W, WANG L, et al. Experimental study and simulation of the stress relaxation characteristics of machine-harvested seed cotton[J]. Applied Sciences, 2021, 11(21): 9959.

[5] FUE K G, BARNES E M, PORTER W M, et al. Visual Control of Cotton-picking Rover and Manipulator using a ROS-independent Finite State Machine[C]//2019 ASABE Annual International Meeting, Boston, US: ASABE, 2019: 1900779.

[6] 牛國梁,李斌,劉洋,等. 我國采棉機發展歷程與研究現狀[J]. 中國農機化學報,2020,41(2):212-218. NIU Guoliang, LI Bin, LIU Yang, et al. Development and research status of cotton picker in China[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(2): 212-218. (in Chinese with English abstract)

[7] HOSSEINALI F, THOMASSON J A. Variability of fiber friction among cotton varieties: Influence of salient fiber physical metrics[J]. Tribology International, 2018, 127: 433-445.

[8] CHEN H X, ZHAO X X, HAN Y C, et al. Competition for light interception in cotton populations of different densities[J]. Agronomy, 2021, 11(1): 176.

[9] 張定文. 新疆呼圖壁縣種植棉花的氣候條件分析[J].北京農業,2015(31):133-134.

[10] ARSHAD A, RAZA M A, ZHANG Y, et al. Impact of climate warming on cotton growth and yields in China and Pakistan: A regional perspective[J]. Agriculture, 2021, 11(2): 97.

[11] 王磊,張宏文,劉巧. 膠棒滾筒棉花采摘頭采收性能試驗[J]. 農業工程學報,2016,32(18):35-41. WANG Lei, ZHANG Hongwen, LIU Qiao. Test on harvest performance of cotton picking head with rubber-bar roller[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(18): 35-41. (in Chinese with English abstract)

[12] 武建設,陳學庚. 新疆兵團棉花生產機械化發展現狀問題及對策[J]. 農業工程學報,2015,31(18):5-10. WU Jianshe, CHEN Xuegeng. Present situation, problems and countermeasures of cotton production mechanization development in Xinjiang Production and Construction Corps[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(18): 5-10. (in Chinese with English abstract)

[13] 陳廷官,張宏文,王磊,等. 水平摘錠式采棉機采摘頭傳動系統優化與試驗[J]. 農業工程學報,2020,36(17):18-26. CHEN Tingguan, ZHANG Hongwen, WANG Lei, et al. Optimization and experiments of picking head transmission system of horizontal spindle type cotton picker[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(17): 18-26. (in Chinese with English abstract)

[14] 陳廷官,張宏文,王磊,等. 水平摘錠式采棉機采摘機構運動特性研究與試驗[J]. 中國農機化學報,2020,41(2):19-25. CHEN Tingguan, ZHANG Hongwen, WANG Lei, et al. Research and experiment on the movement characteristics of the picking mechanism of the horizontal spindle picking cotton picker[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(2): 19-25. (in Chinese with English abstract)

[15] RIZAEV A, MATCHANOV R, YULDASHEV A T, et al. Cotton harvesters for one-time cotton-picking[C]//Materials Science and Engineering, Tashkent, Uzbekistan: IOP Publishing, 2021, 1030(1): 012173.

[16] LI H Y, FU X Q, WANG H B, et al. Research on the wear characteristics of the hook teeth of cotton pickers[J]. Coatings, 2022, 12(6): 762.

[17] 羅樹麗,張有強,馬少輝. 采棉機摘錠磨損機理分析[J]. 塔里木大學學報,2018,30(1):132-137. LUO Shuli, ZHANG Youqiang, MA Shaohui. Wear mechanism analysis on spindle of cotton picker[J]. Journal of Tarim University, 2018, 30(1): 132-137. (in Chinese with English abstract)

[18] 吳蓓,張立新,左玉婷,等. 采棉機水平摘錠材料元素分布研究:基于掃描電鏡/能譜分析[J]. 農機化研究,2013,35(7):174-178. WU Bei, ZHANG Lixin, ZUO Yuting, et al. Research of material elements distribution in cotton picker’s level spindle based on SEM and EDS[J]. Journal of Agricultural Mechanization Research, 2013, 35(7): 174-178. (in Chinese with English abstract)

[19] 吳天松,胡蓉,魯彥志. 采棉機摘錠磨損程度的數字圖像法研究[J]. 機械研究與應用,2017,30(6):159-162. WU Tiansong, HU Rong, LU Yanzhi. Research on the digital image processing method for spindle wear degree of cotton picker[J]. Mechanical Research and Application, 2017, 30(6): 159-162. (in Chinese with English abstract)

[20] 李文春,喬園園,鄧亞猛,等. 水平摘錠鉤齒磨損的評價與分析[J]. 中國農機化學報,2018,39(3):11-14. LI Wenchun, QIAO Yuanyuan, DENG Yameng, et al. Evaluation and analysis of hook tooth wear for cotton picker spindle[J]. Joural of Chinese Agricultural Mechanization, 2018, 39(3): 11-14. (in Chinese with English abstract)

[21] 吳天松,胡蓉,魯彥志. 采棉機摘錠磨損的自動檢測及摘錠壽命預測[J]. 機械,2018,45(4):32-37. WU Tiansong, HU Rong, LU Yanzhi. Automatic inspection of cotton picking spindle and its life prediction[J]. Machinery, 2018, 45(4): 32-37. (in Chinese with English abstract)

[22] 張有強,蔡志鵬,田煜,等. 電磁處理提升采棉機摘錠力學性能和耐磨性[J]. 農業工程學報,2018,34(7):31-37. ZHANG Youqiang, CAI Zhipeng, TIAN Yu, et al. Improvement of mechanical properties and wear resistance of cotton picker spindle by electromagnetic treatment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(7): 31-37. (in Chinese with English abstract)

[23] MENG F M, CHEN Y P, YANG Y, et al. Friction and wear behavior of electroless nick coating used for spindle of cotton picker[J]. Industrial Lubrication and Tribology, 2016, 68(2): 220-226.

[24] BAKER K D, DELHOM C D, HUGHS S E. Spindle diameter effects for cotton pickers[J]. Applied Engineering in Agriculture, 2017, 33(3): 321-327.

[25] BAKER K D, HUGHS E, FOULK J. Spindle speed optimization for cotton pickers[J]. Applied Engineering in Agriculture, 2015, 31(2): 217-225.

[26] BAKER K D, HUGHS E, FOULK J. Cotton quality as affected by changes in spindle speed[J]. Applied Engineering in Agriculture, 2010, 26(3): 363-369.

[27] MENG F M, CHEN N W, CHEN Z W. Hard chromium coating effects on tribological performances for nonlubricated and lubricated spindle of cotton picker[J]. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 2016, 230(2): 446-453.

[28] WANG L, YIN C H, ZHANG L C, et al. Analysis and experiment on the impact of various hook angle factors on spindle picking performance[J]. Agriculture, 2022, 12(6): 768.

[29] 吳蓓. 采棉機水平摘錠材料及熱處理工藝分析[D]. 石河子:石河子大學,2013. WU Bei. The Analysis of Cotton-Picker Level Spindle’s Material and Heat Treatment Process[D]. Shihezi: Shihezi University, 2013. (in Chinese with English abstract)

[30] 古麗扎代姆·阿木提. 自走式采棉機關鍵零部件的材料分析及優化[D]. 烏魯木齊:新疆大學,2014. GURIZADEEM·Amuti. Since the Material Analysis and Optimization of Key Parts of Cotton Picker[D]. Urumchi: Xinjiang University, 2014. (in Chinese with English abstract)

[31] 鄧亞猛,李文春,俞天柱,等. 水平摘錠式采棉機的摘錠磨損因素分析與研究[J]. 中國農機化學報,2017,38(9):11-13. DENG Yameng, LI Wenchun, YU Tianzhu, et al. Analysis and study on spindle component wear factors of horizontal cotton picker[J]. Journal of Chinese Agricultural Mechanization, 2017, 38(9): 11-13. (in Chinese with English abstract)

[32] ZHANG Y Q, TIAN Y, MENG Y G. Wear behavior of spindles of cotton picker in field work[J]. Journal of Tribology, 2021, 143(2): 021703.

[33] 張有強,王偉,廖結安. 采棉機摘錠磨損失效分析[J]. 農業工程學報,2017,33(18):45-50. ZHANG Youqiang, WANG Wei, LIAO Jie’an. Wear failure analysis on spindle of cotton picker[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(18): 45-50. (in Chinese with English abstract)

[34] GU Y Q, ZHANG H W, FU X Q, et al. Experimental wear behavior analysis of coated spindle hook teeth under real harvesting work conditions[J]. Materials, 2021, 14(10): 2487.

[35] GU Y Q, ZHANG H W, FU X Q, et al. Comparative analysis of the wear performance of spindle hook teeth during fieldwork[J]. Journal of Tribology, 2022, 144(1): 011706.

[36] GLENN D. Cotton picker spindle: US4483132A[P]. 1984-11-20.

[37] AMANOV A, SEMBIRING J P B A, AMANOV T. Experimental investigation on friction and wear behavior of the vertical spindle and V-belt of a cotton picker[J]. Materials, 2019, 12(5): 773.

[38] 張宏文,谷艷清,王軍,等. 一種具有仿形結構鉤齒的采棉機用摘錠:CN112514651B[P]. 2021-10-08.

[39] 張宏文,李海洋,金永遜,等. 一種鉤齒經過鈍化處理的采棉機摘錠:CN113994812B[P]. 2022-10-25.

[40] 周文卿. 采棉機采凈率的影響因素研究[D]. 阿拉爾:塔里木大學,2020. ZHOU Wenqing. Study on the Factors Affecting the Harvesting Rate of Cotton Pickers[D]. Alar: Tarim University, 2020. (in Chinese with English abstract)

[41] 羅樹麗. 機采棉株型特征與采凈率研究[D]. 阿拉爾:塔里木大學,2018. LUO Shuli. Research on Plant Type Characteristics and Recovery Rate of Cotton Picking[D]. Alar: Tarim University, 2018. (in Chinese with English abstract)

[42] 王由之,張宏文,王磊,等. 基于模糊PID控制的棉花采摘性能試驗臺測控系統研制[J]. 農業工程學報,2018,34(23):23-32. WANG Youzhi, ZHANG Hongwen, WANG Lei, et al. Development of measurement and control system for cotton picking performance test bench based on fuzzy PID control[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(23): 23-32. (in Chinese with English abstract)

[43] 張恒恒,王香茹,胡莉婷,等. 不同機采棉種植模式和種植密度對棉田土壤水熱效應及產量的影響[J]. 農業工程學報,2020,36(23):39-47. ZHANG Hengheng, WANG Xiangru, HU Liting, et al. Effects of different machine-harvested cotton planting patterns and planting densities on soil hydrothermal conditions and cotton yield[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(23): 39-47. (in Chinese with English abstract)

[44] 張昊,林濤,湯秋香,等. 種植模式對機采棉冠層光能利用與產量形成的影響[J]. 農業工程學報,2021,37(12):54-63. ZHANG Hao, LIN Tao, TANG Qiuxiang, et al. Effects of planting pattern on canopy light utilization and yield formation in machine-harvested cotton field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(12): 54-63. (in Chinese with English abstract)

[45] KORZYNSKI M, DZIERWA A, PACANA A, et al. Fatigue strength of chromium coated elements and possibility of its improvement with ball peening[J]. Surface and Coatings Technology, 2009, 204(5): 615-620.

[46] DZIERWA A, PAWLUS P, REIZER R. Surface topography of chromium coatings after pneumatic ball peening[C]//Key Engineering Materials, Switzerland: Trans Tech Publications Ltd, 2008: 113-116.

[47] KORZYNSKI M, PACANA A, CWANEK J. Fatigue strength of chromium coated elements and possibility of its improvement with slide diamond burnishing[J]. Surface and Coatings Technology, 2009, 203(12): 1670-1676.

[48] 畢新勝. 采棉機采摘頭水平摘錠工作機理的研究[D]. 石河子:石河子大學,2007. BI Xinsheng. Study on Working Mechanism of Horizontal Spindle Picking of Cotton Picker[D]. Shihezi: Shihezi University, 2007. (in Chinese with English abstract)

[49] 劉秀梅. 水平摘錠式采棉機摘錠采摘機理的研究[D]. 石河子:石河子大學,2019. LIU Xiumei. Study on the Picking Mechanism of Spindle of Horizontal Cotton Picker[D]. Shihezi: Shihezi University, 2019. (in Chinese with English abstract)

[50] 劉秀梅,張宏文,王磊,等. 水平摘錠式采棉機摘錠采棉的纏繞模型研究[J]. 農機化研究,2020,42(8):13-19. LIU Xiumei, ZHANG Hongwen, WANG Lei,et al. Study on winding model of spindle picking cotton for horizontal cotton picker[J]. Journal of Agricultural Mechanization Research, 2020, 42(8): 13-19. (in Chinese with English abstract)

[51] 張龍唱,張宏文,王磊,等. 不同鈴殼物理參數對機采棉采摘力學特性的影響[J]. 農業工程學報,2020,36(19):30-37. ZHANG Longchang, ZHANG Hongwen, WANG Lei, et al. Influence of different boll shell physical parameters on mechanical properties of machine-harvested cottons[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(19): 30-37. (in Chinese with English abstract)

Experimental study on the wear resistance of spindle and cotton total harvest rate under field conditions

LI Haiyang1,2, WANG Yugang3, FU Xiuqing4, ZHANG Hongwen1,2※, WANG Lei1,2, WANG Meng1,2, DU Xintian1,2, WEI Ximei1,2, FU Xuewen1,2, HAN Bingdong1,2

(1.,,832003,;2.,832003;3.,250032,; 4.,,210031,)

Cotton is one of the most important economic crops and strategic materials in national defense, medicine, and industry. Mechanized harvesting of cotton has been an effective way to promote the development of the cotton industry in China. Among them, a large cotton harvesting equipment, a cotton picker has been widely used in Xinjiang in western China, due to the fast, convenient, and low labor intensity. The spindle is the commonly-used core component in the cotton picker. The product quality and wear resistance of the spindle can determine the operation efficiency, quality, and economy of the cotton picker. The wear failure of the spindle is mainly manifested in the serious wear to the hook teeth. The hook teeth are the key structure of the spindle hooking and winding the cotton. Moreover, the hook teeth are in contact with the cotton plant, the bell shell, the sand, and hard particles during the operation of the cotton picker, leading to damage and peeling from the hook tooth coating. The failure of spindle hook teeth can be caused to couple with the complex and changeable field operating environment. The rear tooth tip and the tooth edge of the hook tooth were concentrated in the process of cotton picking or removal, due to the stresses of the front tooth tip. The wear in the hook tooth can often start from these parts, leading to the low wear resistance of the hook tooth. The electrolytic method can be used to passivate the front tooth tip, the rear tooth tip, and the tooth edge of the spindle hook teeth before the electroplating of the spindle, in order to improve the wear resistance of the spindle hook teeth, particularly for the service life and the collection rate of the spindle during harvesting. This study aims to explore the wear resistance of the passivated spindle and the cotton collection rate under field conditions. The unpassivated spindle and the passivated spindle were installed on different picking heads of the cotton picker. Once the working area of the cotton picker reached 0, 150, 300, 450, and 600 hm2, two kinds of spindle samples were obtained and cut for sample preparation. The wear morphology of the hook teeth was analyzed to extract the wear area of the hook teeth and the thickness of the coating. The collection rate of the two kinds of spindles was measured after harvesting. The results show that the front tooth tip of the unpassivated spindle hook tooth was easy to break, whereas, the peeling of the passivation spindle hook tooth coating was later than that of the unpassivated spindle. There was a smaller wear area of the passivated spindle hook teeth, and the coating thickness was higher at the test position under the working areas. When the working area reached 600 hm2, the wear area of the unpassivated spindle No.1 hook tooth reached 8.8×105μm2, which was about 2.3 times of the passivated spindle No.1 hook tooth. There was the peeled-off coating of unpassivated hook teeth No.1 and No.2, as well as the passivated hook teeth No.1 at the test position. The passivated spindle performed better wear resistance, in terms of the wear morphology, wear area, and coating thickness. Furthermore, the collection rate of the passivated spindle was 0.2 percentage points lower than that of the unpassivated one. When the working area reached about 200 hm2, there was little difference between the collection rate two kinds of spindles. Once the working area exceeded 200 hm2, the collection rate of the passivated spindle was greater than that of the unpassivated spindle. When the working area reached 450 hm2, the collection rate of unpassivated and passivated spindles reached the maximum, which was about 96.4 % and 96.7 %, respectively. When the working area reached 600 hm2, the average wear area of the unpassivated spindle hook tooth reaches 2.9×105μm2, which was about 2.6 times of the passivated spindle hook tooth, and the collection rate of the passivated spindle was 0.5 percentage points higher than that of the unpassivated spindle, indicating the better picking performance of passivated spindle. The finding can provide great significance for the structural optimization and modification of the hook teeth of the cotton picker.

agricultural machinery; cotton; spindle; passivation; wear resistance; wear morphology; harvest rate

2022-10-20

2023-03-13

石河子大學創新發展專項項目(CXFZ202015);兵團重大科技項目(2018AA008);中央高校基本科研業務費專項基金(KYLH2022002)

李海洋,研究方向為機械工程。Email:20202109054@stu.shzu.edu.cn

張宏文,博士,教授,博士生導師,研究方向為農業機械設計及機械系統仿真。Email:zhw_mac@shzu.edu.cn

10.11975/j.issn.1002-6819.202210173

S233.4

A

1002-6819(2023)-07-0089-09

李海洋,王玉剛,傅秀清,等. 田間作業條件下摘錠耐磨性能及棉花采凈率的試驗研究[J]. 農業工程學報,2023,39(7):89-97. doi:10.11975/j.issn.1002-6819.202210173 http://www.tcsae.org

LI Haiyang, WANG Yugang, FU Xiuqing, et al. Experimental study on the wear resistance of spindle and cotton total harvest rate under field conditions[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(7): 89-97. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.202210173 http://www.tcsae.org