PAC與PAM復(fù)合絮凝劑處理泡菜廢水

楊紅梅++谷晉川++張德航++歐陽杰++冉孟家

摘要:

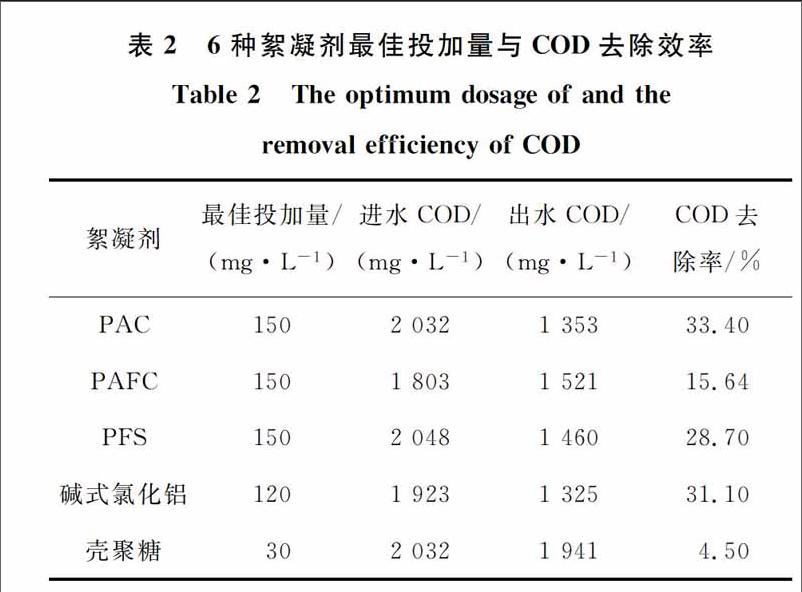

采用絮凝法對泡菜廢水進(jìn)行了試驗(yàn),分別考察了絮凝劑的種類、助凝劑的種類、PAM分子量、投加方式、pH值、溫度、攪拌轉(zhuǎn)速等條件對泡菜廢水絮凝處理效果的影響,為泡菜廢水的后期生化處理提供了幫助的同時(shí)也可為泡菜廠實(shí)際絮凝處理提供一定的參考。在含大量NaCl的泡菜廢水中,利用PAM網(wǎng)捕、架橋功能完善了PAC單獨(dú)作用下絮體細(xì)小松散的缺陷,改善了絮凝和沉降性能。研究結(jié)果表明:PAC用量150 mg/L,PAM用量25 mg/L,pH6,溫度30 ℃,250 r/min快攪2 min,90 r/min慢攪2 min,靜置30 min后泡菜廢水COD、濁度去除率分別達(dá)到了37.7%、96.7%。

關(guān)鍵詞:

泡菜廢水;絮凝劑;助凝劑;去除率

Abstract:

With the flocculation test carried out on the pickled cabbage water, the type of flocculant and coagulant, molecular mass of PAM, sequence of addition, pH, temperature, and stirring speed are investigated on the effect of flocculation treatment of pickle waste water, which makes the next stages of biochemical treatment more easily and provides a reference for the selection of the flocculation parameters of kimchi factory. In the pickled cabbage wastewater which contains a large number of NaCl, the flocculation and sedimentation performance are improved by the addition of PAM because of its bridging functions. Under the condition of PAC dosage of 150 mg/L, PAM dosage of 25 mg/L, pH6, at the temperature of 30 ℃, by 2 minutes of a magnetic stirrer stirring (250 rpm/min) and a slow stirring (90 rpm/min), static 30min, the best result is obtained. The removal rate of COD and turbidity reaches 37.7%, 96.7%.

Keywords:

pickle wastewater;flocculant;coagulant;removal rate

近年來,四川泡菜行業(yè)蓬勃發(fā)展,泡菜產(chǎn)量位居全國之首,各種各樣的泡菜產(chǎn)品受到關(guān)注與青睞[13]。泡菜廢水的差異隨季節(jié)變化波動較大,且排放量大。泡菜廢水里含有的有機(jī)物、氮、磷營養(yǎng)鹽可造成水體富營養(yǎng)化,同時(shí),高含鹽量的泡菜廢水直接排入土壤會造成土壤嚴(yán)重的鹽堿化[14]。泡菜廢水直接排入水體不僅會對環(huán)境造成威脅,也導(dǎo)致大量鹽分流失,造成資源的流失,因此,鹽分的綜合回收利用逐漸引起環(huán)境管理部門的重視[3],而絮凝即是第一步,目的是去除廢水中一部分有機(jī)物和濁度,為后續(xù)處理提供基礎(chǔ)。

目前,食品廢水的處理方法主要有生物法、 吸附法、氧化法等,混凝法是常用方法之一[47]。絮凝處理主要是去除水體中的溶膠和懸浮體,包括無機(jī)物和有機(jī)物。從表觀而言就是常用的濁度、色度、COD、BOD等指標(biāo),同時(shí),也能部分地去除一些溶解性的雜質(zhì)[67]。……