高原環境條件下柴油機增壓與噴油參數協同優化

焦宇飛,劉瑞林,張眾杰,周廣猛,楊春浩,馬家明

高原環境條件下柴油機增壓與噴油參數協同優化

焦宇飛1,劉瑞林2※,張眾杰1,周廣猛2,楊春浩3,馬家明1

(1. 陸軍軍事交通學院,學員五大隊,天津 300161;2. 陸軍軍事交通學院,軍用車輛工程系,天津 300161;3. 海軍工程大學,動力工程學院,湖北 武漢 430033)

增壓與噴油是影響柴油機高海拔性能最直接的因素。為了優化柴油機不同海拔條件下增壓與噴油系統協同控制策略,建立了二級可變截面增壓柴油機GT-Power仿真模型,計算得到了柴油機運行各工況數據。將神經網絡與仿真數據相結合,以動力性為優化目標,得到不同海拔條件下增壓與噴油系統協同優化規律。研究結果表明:相比于原機,噴油參數經過優化后,最佳循環噴油量增加,增加量呈現出自最大轉矩轉速點向兩側逐漸增大的趨勢。最佳噴油提前角,在2 500 和5 500 m低轉速下平均分別增加了1和1.5 ℃A,在中高轉速下,平均分別減小了25.2%和17.5%。相比于原機,最佳可變截面的渦輪增壓器(variable geometry turbocharged,VGT)葉片開度增大,但增大趨勢在不同海拔略有不同,0 m海拔時,增加幅度隨轉速增加而增大,5500 m低轉速時,開度不變,中高轉速時,VGT開度增加幅度隨轉速增加呈現先增大后減小。增壓與噴油參數協同優化后,0 m海拔時,VGT葉片開度和噴油量增大,噴油提前角減小,5 500 m海拔時,低轉速下VGT葉片開度不變,循環噴油量和噴油提前角增大,中高轉速下VGT葉片開度和循環噴油量增大,噴油提前角減小。

柴油機;優化;高海拔;二級可調增壓系統;噴油參數

0 引 言

高原條件下,受大氣壓力與溫度影響,空氣密度明顯降低,柴油機在高原運行時,油與氣失配使得柴油機燃燒惡化,導致柴油機動力、經濟性下降、爆壓超限、渦輪增壓器超溫、超速等一系列問題[1-5]。

改善增壓與噴油系統是解決上述問題的有效途徑[6-7]。對于可變截面增壓柴油機,進氣主要通過調節增壓系統的可變幾何截面增壓(variable geometry turbocharged,VGT)葉片開度實現,噴油主要依靠改變噴油參數來實現。王利民等[8]提出了基于進氣增壓壓力和位置開度的VGT多級閉環控制算法,實現了柴油機全工況增壓壓力的閉環控制。唐蛟等[9]提出了廢氣再循環系統(exhaust gas recirculation,EGR)與VGT解耦控制策略,縮短了增壓壓力和進氣質量流量的上升時間。朱振夏[10]根據供油參數影響規律,提出了“邊界適應度歸零”的懲罰參數取值方法,通過優化使得柴油機4 500 m標定點功率相對原機提升了14.7%,燃油消耗率降低了9.6%。

變海拔條件下,單級增壓和調節能力比較有限,難以滿足柴油機不同海拔、變工況需求的狀況[11],近些年來可調二級增壓系統受到越來越多的關注[12-14]。吉林大學的騰鵬坤[15]研究了噴油和供氣策略對二級增壓柴油機瞬變性能的影響,該校的袁興[16]提出了復合EGR控制策略對二級增壓柴油機瞬變性能的影響,通過對控制策略優化有效改善了柴油機排放特性。軍事交通學院的董素榮等[11]研究了不同海拔條件二級增壓器與柴油機的匹配特性,得到了VGT開度對二級增壓柴油機高海拔燃燒特性的影響。北京理工大學李長江[17]借助于GT-Power建立了可調二級增壓系統模型,開展了二級增壓器渦輪旁通流量率隊增壓系統的影響以及二級增壓器高原條件下穩態與瞬態調節方法。但以上研究偏向于對二級增壓器特性的研究,而柴油機性能受噴油與進氣共同影響,單獨只研究二級增壓器對柴油機燃燒效率提升較為有限,對增壓與噴油參數協同控制對充分發揮二級可調增壓系統潛力,有效提升柴油機高海拔動力性有著重要意義。但針對不同海拔條件下,二級可調增壓與噴油參數協同優化國內外還鮮有報道。

據此,本文開展了相關研究,利用GT-Power建立柴油機仿真模型并通過試驗方法進行驗證。借助仿真模型計算不同海拔工況點,篩選出具有代表性的點進行神經網絡的訓練,得到了增壓與噴油參數優化規律,提出了增壓與噴油參數協同優化策略。

本文的研究為優化柴油機高海拔燃燒效率,全面提升柴油機高海拔性能提供技術支撐。

1 模型的建立與驗證

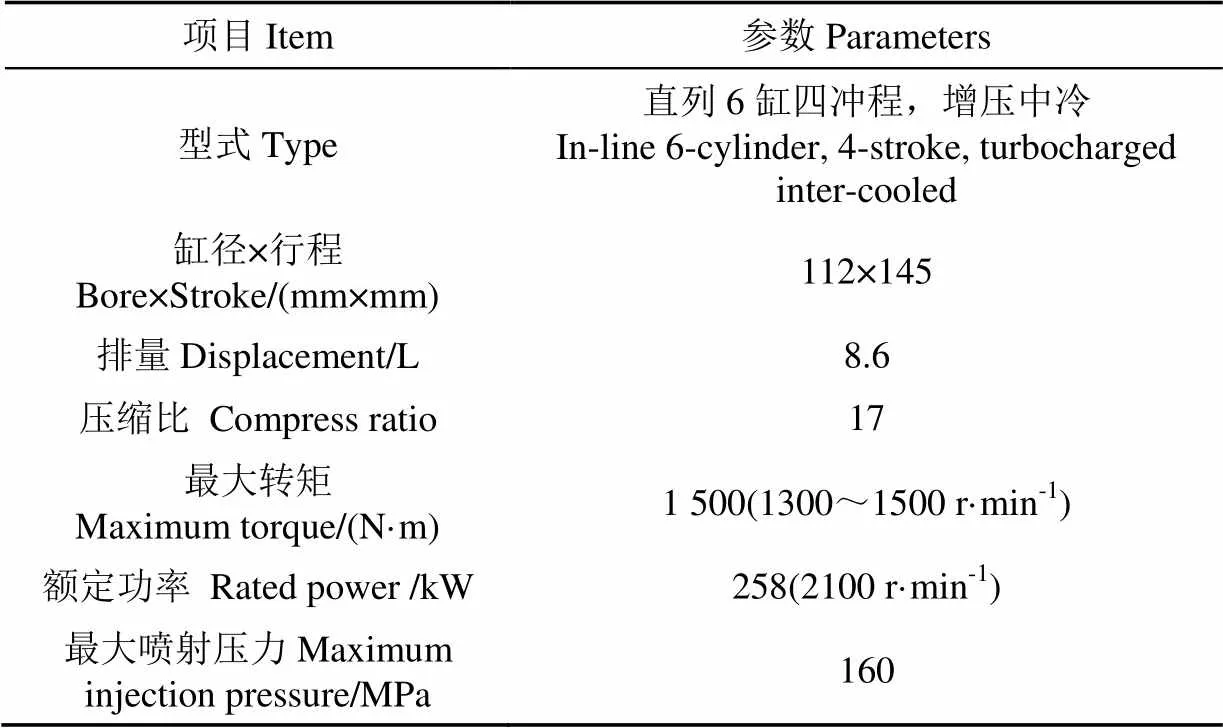

試驗采用一臺6缸高壓共軌增壓中冷柴油機,主要技術參數如表1所示。

表1 柴油機主要技術參數

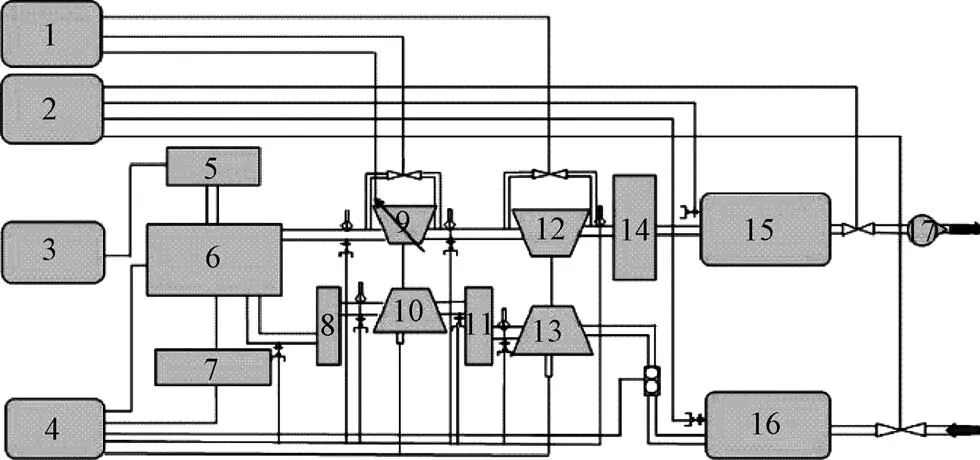

海拔模擬通過內燃機高原環境模擬試驗臺實現,該試驗臺通過進氣節流和排氣抽真空的方式能夠模擬0~6 000 m海拔的大氣壓力,控制精度在±5%。試驗設備主要包含CW440D電渦流測功機、進排氣壓力控制系統、AVL670燃燒分析儀、上海同圓CMFD瞬態油耗儀、上海同圓LQY600冷卻液恒溫系統、數據采集系統等,發動機臺架詳細布置如圖1所示。

1.二級增壓控制系統 2.進排氣壓力控制系統 3.發動機控制系統 4.數據采集系統 5.測功機 6.發動機 7.瞬態油耗儀 8.中冷器 9.高壓級渦輪 10.高壓級壓氣機 11.中冷器 12.低壓級渦輪 13.低壓級壓氣機 14.換熱器 15.排氣穩壓箱 16.進氣穩壓箱 17.真空泵

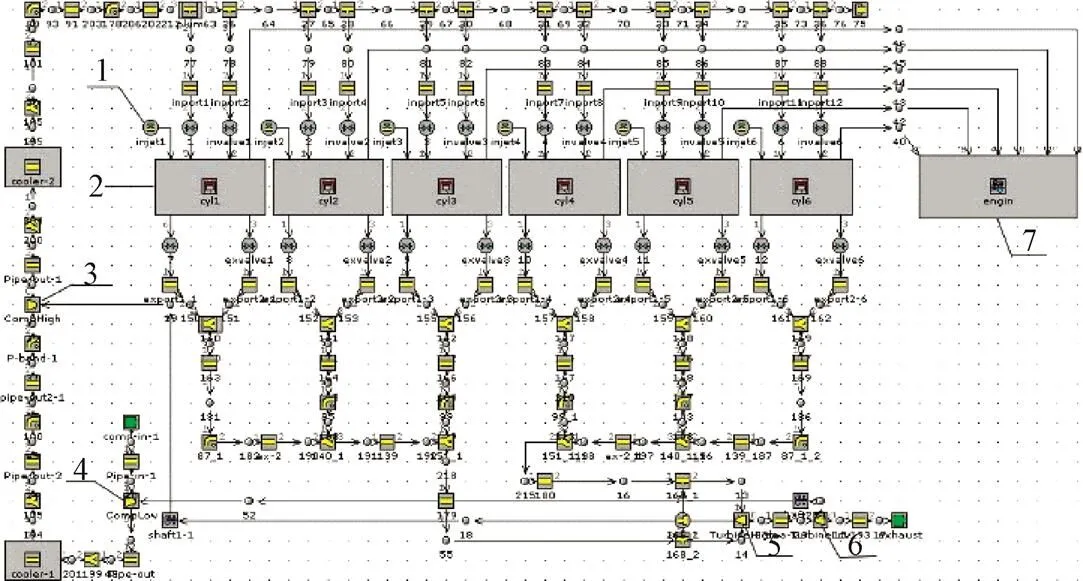

根據內燃機實際結構,利用GT-Power建立了如圖2所示的二級可調增壓柴油機工作過程模型。該二級可調增壓系統以普通廢氣渦輪增壓器為低壓級,以VGT為高壓級,兩級增壓器以串聯的形式相連。VGT葉片開度定義為:當前VGT葉片開度對應噴嘴環流通面積與最大VGT葉片開度對應的噴嘴環流通面積之比。燃燒模型采用GT-Power中的油滴蒸發模型進行燃燒過程模擬[18],傳熱模型直接采用量綱分析得到的半經驗的Woschni傳熱模型[19],渦輪增壓器模型主要根據實際渦輪機運行的速度和效率特性以及壓氣機運行特性進行設置。在噴油過程中的噴油定時和循環噴油量則根據實際工況直接進行設置。

1.噴油器 2.氣缸 3.高壓級壓氣機 4.低壓級壓氣機 5.高壓渦輪機 6.低壓級渦輪機 7.曲軸箱

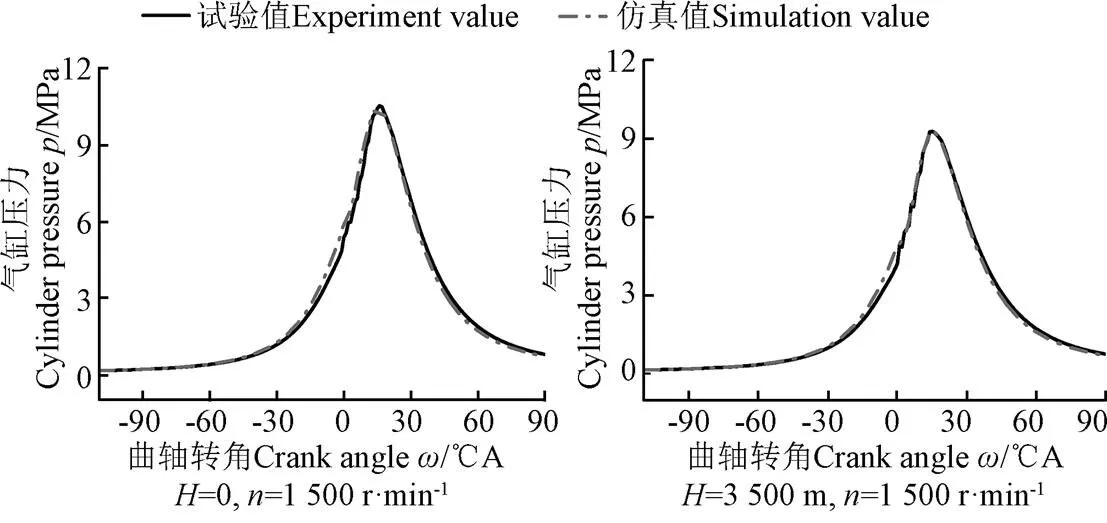

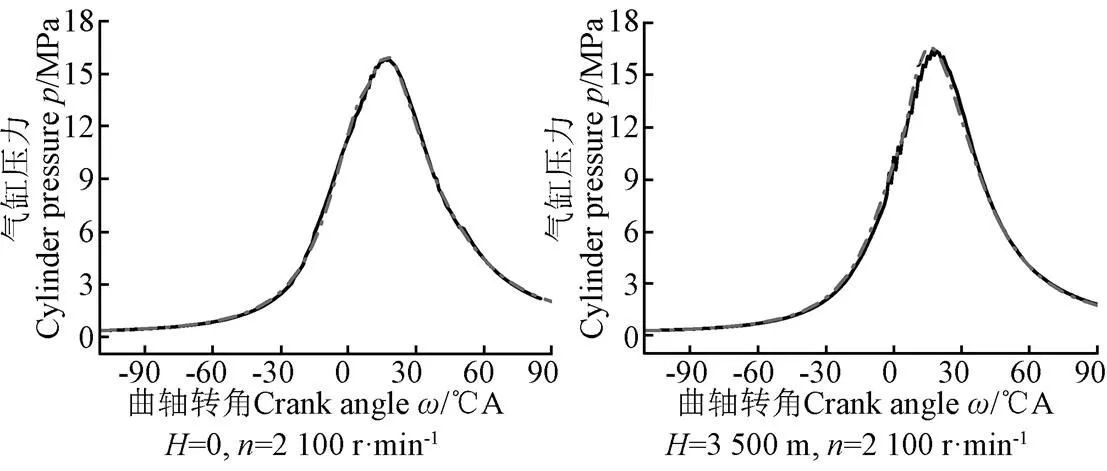

在仿真模型的驗證中,為了充分驗證模型的準確性,選取具有典型的海拔與工況點進行驗證,本文選取0與3 500 m為驗證海拔,選取最大轉矩轉速點與額定功率點全負荷和部分負荷工況點作為驗證工況。圖3為各工況點試驗與仿真結果的驗證結果。由圖可知,各海拔轉速下,柴油機缸壓與放熱率的仿真值與試驗值能夠較好地吻合,誤差在5%以內,可以用于高原柴油機性能仿真計算。

a. 部分負荷工況

a. Partial load condition

b. 全負荷工況

b. Full load condition

注:為海拔高度;為轉速。Note:is the altitute;is the engine speed.

圖3 仿真結果驗證

Fig.3 Verification of simulation results

2 增壓與噴油系統協同優化流程

2.1 增壓與噴油系統協同優化方案

全負荷工況下增壓與噴油系統協同優化涉及到循環噴油量、噴油提前角及VGT葉片開度3個控制參數。控制參數與柴油機輸出轉矩之間沒有明確的函數關系,采用傳統試湊法[20]及正交試驗法[21]無法滿足優化要求,神經網絡模型可以建立起輸入與輸出的映射關系,并且具有較強的預測計算能力,對于柴油機多參數優化問題具有較強的適用性[22-24]。

基于神經網絡的增壓與噴油系統優化主要包含3個過程:通過仿真試驗篩選數據樣本,神經網絡模型的建立及訓練與運用尋優函數實現優化[25-26]。具體流程為:在已建立的GT-Power仿真模型的基礎上,設置柴油機實際工作工況點,對各工況點進行仿真試驗,在試驗結果中篩選出轉矩較大且最高燃燒壓力和空燃比符合預定要求的數據作為輸入樣本訓練神經網絡,得到輸入變量與輸出轉矩之間的映射關系,而后擴大參數取值范圍,并縮小調節步長以提高各參數調節精度,設計新的輸入組合,并用導入訓練好的神經網絡預測輸出轉矩。使用Matlab軟件中max函數與find函數分別求得輸出轉矩極大值及其對應位置,可得最大轉矩對應的輸入組合,將其代入仿真模型進行驗證,根據限制條件作適當調整,最終確定該工況下基于動力性最優的各參數協同優化組合。

2.2 訓練樣本的生成

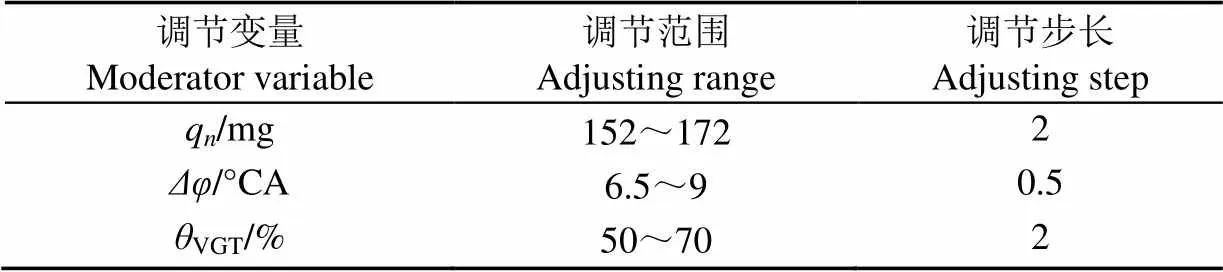

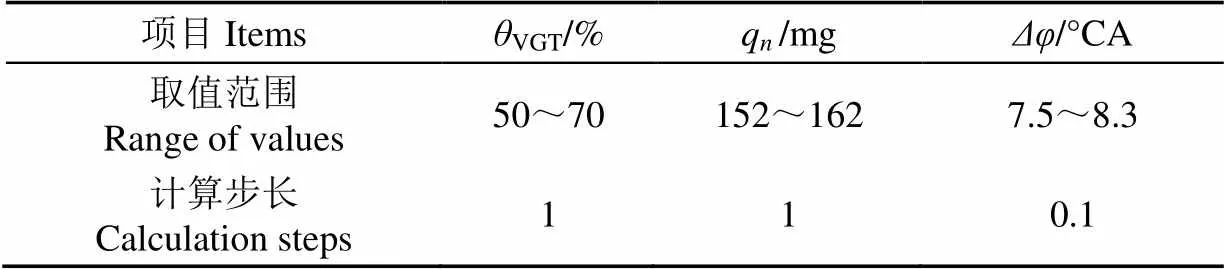

針對柴油機運行工況,選取VGT葉片開度與噴油參數進行全排列,以=2 500 m,=1 800 r/min為例,根據柴油機實際噴油參數設置仿真參數如表2所示。

表2 仿真試驗參數設置

注:q為循環噴油量;為噴油提前角;VGT為VGT開度。

Note:qis the circulating fuel injection quantity;is the injection advance angle;VGTis the opening of the VGT.

柴油機運行過程中,為了防止柴油機最高燃燒壓力超過限制而燒壞柴油機,最高燃燒壓力限制在16 MPa。為了降低柴油機燃燒過程中熱負荷過高造成柴油機拉缸,提升柴油機燃燒效率,將空燃比限定在19.5~21范圍內。將所有調節參數組合作為有效輸出樣本,若不滿足限定條件則剔除該點,共篩選出128個樣本作為有效樣本,部分篩選過程如表3所示。

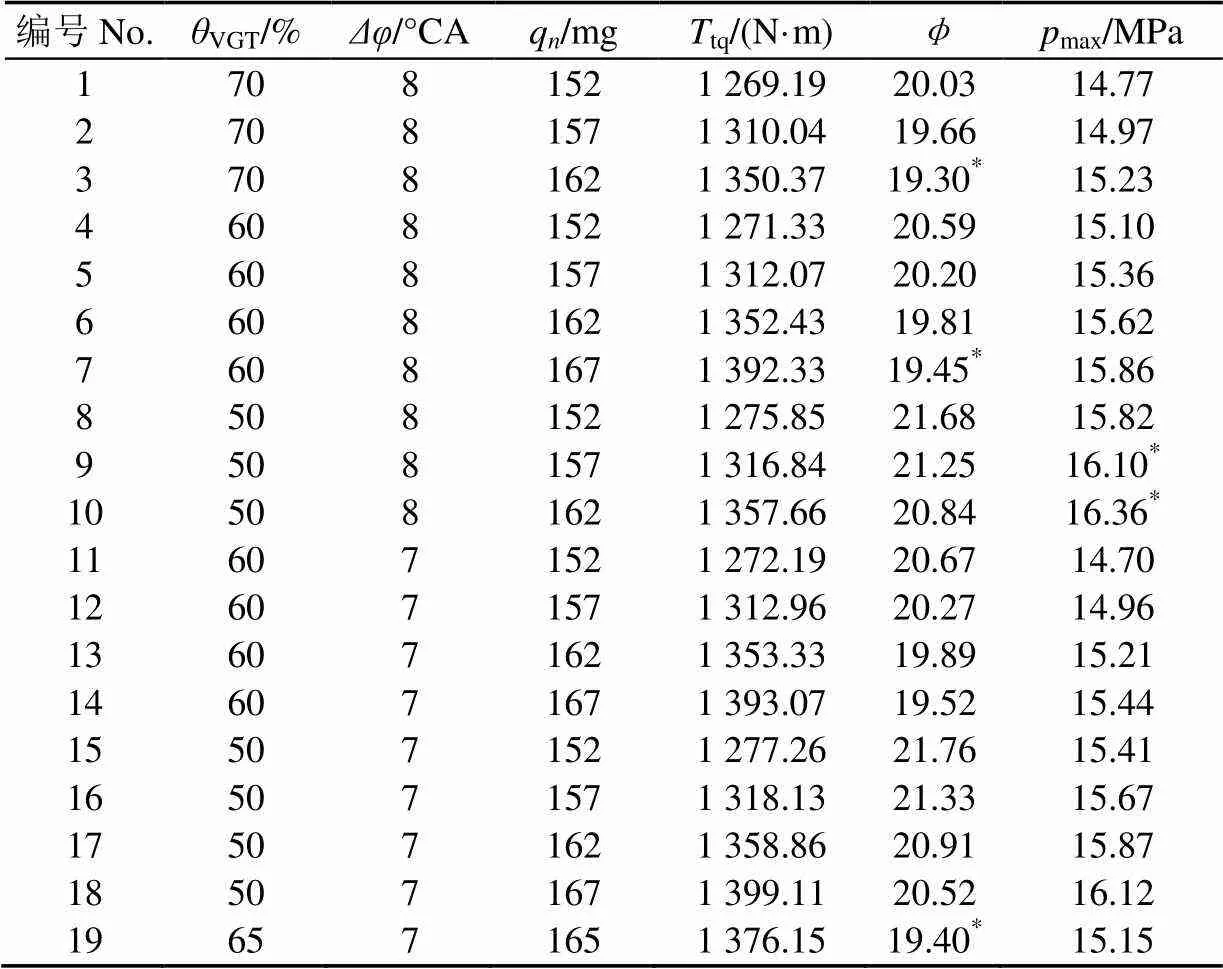

2.3 神經網絡模型的建立及訓練

神經網絡模型包含輸入層、隱含層和輸出層。輸入層為柴油機協同優化控制參數,共包含循環噴油量、噴油提前角、VGT葉片開度3個參數。本文優化是以動力性最大為優化目標,因此輸出層只包含1個轉矩參數。為提高神經網絡準確性,設置2層隱含層,第1層為3層,第2層為6層,如圖4所示。

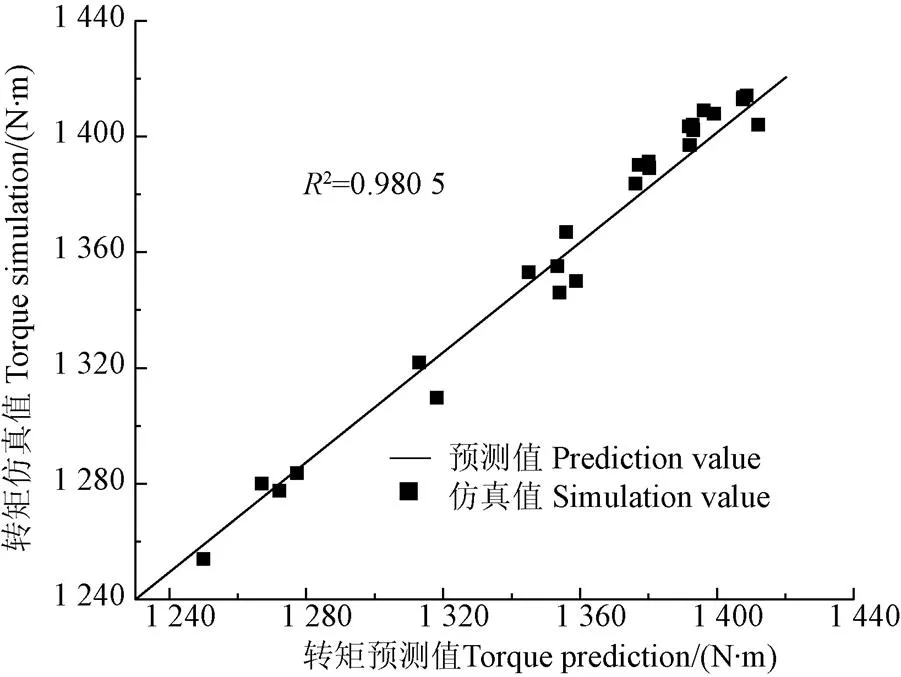

將仿真試驗篩選得到的增壓與噴油系統控制參數組合及其對應的轉矩數據,建立成訓練樣本,設置學習率為1,最大校正次數為100 000,對神經網絡進行訓練。選取樣本外的25組仿真數據,運用訓練好的神經網絡進行預測,得到輸出轉矩預測值與仿真值誤差如圖5所示,預測值與仿真值誤差較小,神經網絡模型預測精度符合要求,可用于下步預測。

表3 H=2 500 m,n=1 800 r·min-1工況下部分有效數據樣本的篩選

注:圖中標*為剔除掉的參數組合。T為柴油機轉矩;為空燃比;max為最高燃燒壓力。

Note: The dots marked with * in the figure are the deleted parameter combinations. Tis the engine torque;is the air-fuel ratio;maxis the maximum cylinder pressure.

圖4 神經網絡模型的建立

圖5 模型預測準確性驗證

2.4 協同優化組合的確定

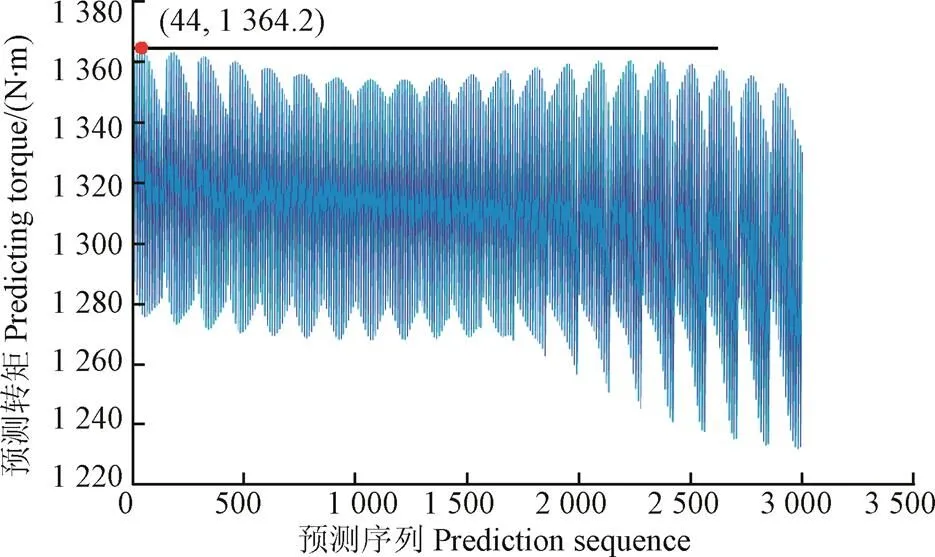

通過神經網絡建立起增壓和噴油系統控制參數與轉矩之間的映射關系。基于訓練好的神經網絡,取表4中3個參數取值的全排列,建立新的輸入組合共21×11×13=3 003組,輸入神經網絡中可預測出3 003組輸出,在Mtalab中對輸出轉矩數組調用max函數,可得到極值點轉矩為1 364.2 N·m,再調用find函數,可得轉矩極大值對應位置為第44組序列,即最大轉矩對應第44組輸入,神經網絡預測的轉矩極大值及對應位置如圖6所示。

表4 輸入組合參數設置

圖6 預測轉矩極值點及對應位置

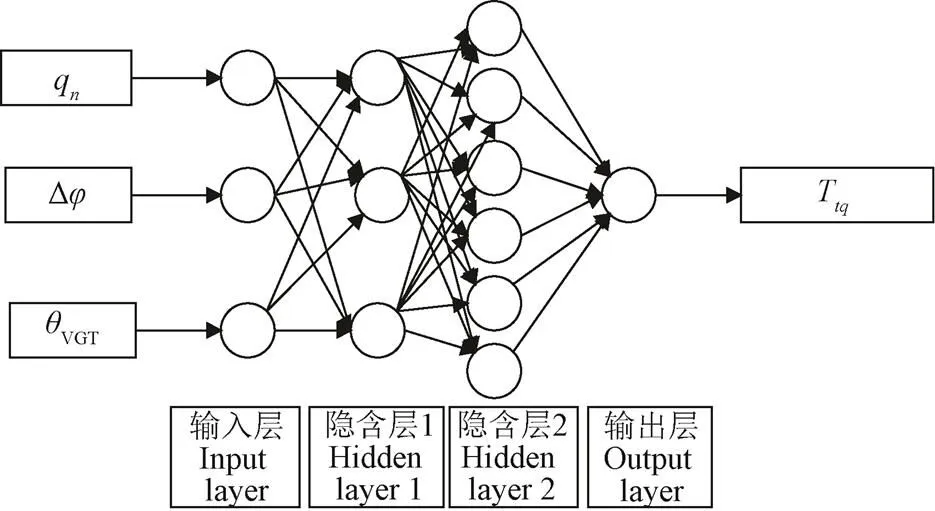

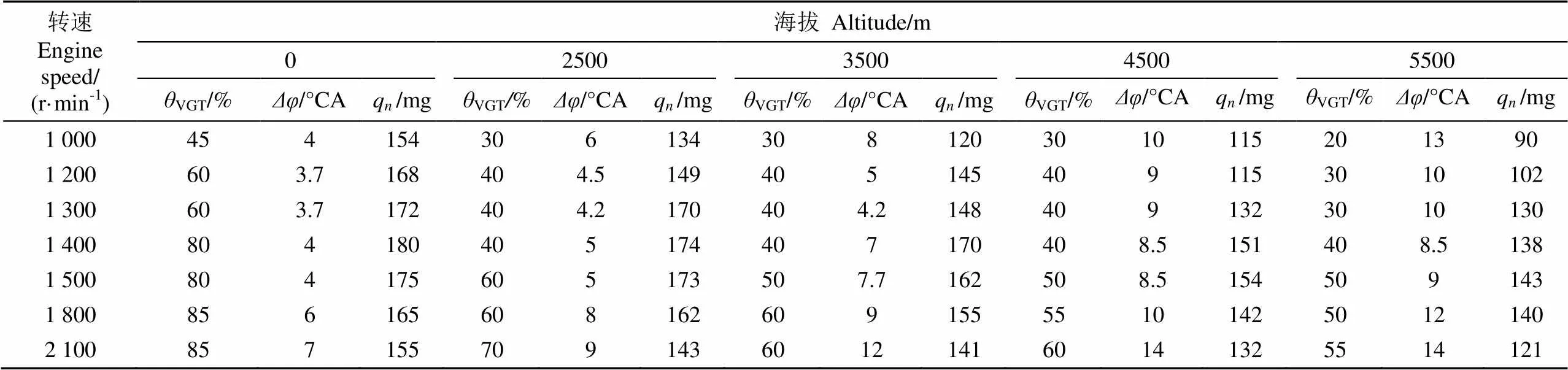

通過在二級可調增壓柴油機仿真模型中設置柴油機不同海拔與工況,用上述協同優化方法可得出0~5 500 m海拔,1 000~2 100 r/min轉速全負荷條件下,噴油量、噴油提前角及VGT葉片開度協同優化組合如表5所示。

表5 不同海拔控制參數優化值

3 增壓與噴油系統控制參數協同優化變化規律

基于神經網絡得到不同海拔不同轉速下增壓與噴油控制參數的協同優化組合后,分析噴油量、噴油提前角及VGT葉片開度隨海拔及轉速的變化規律,為增壓與噴油系統控制參數協同控制策略的制定提供參考依據。

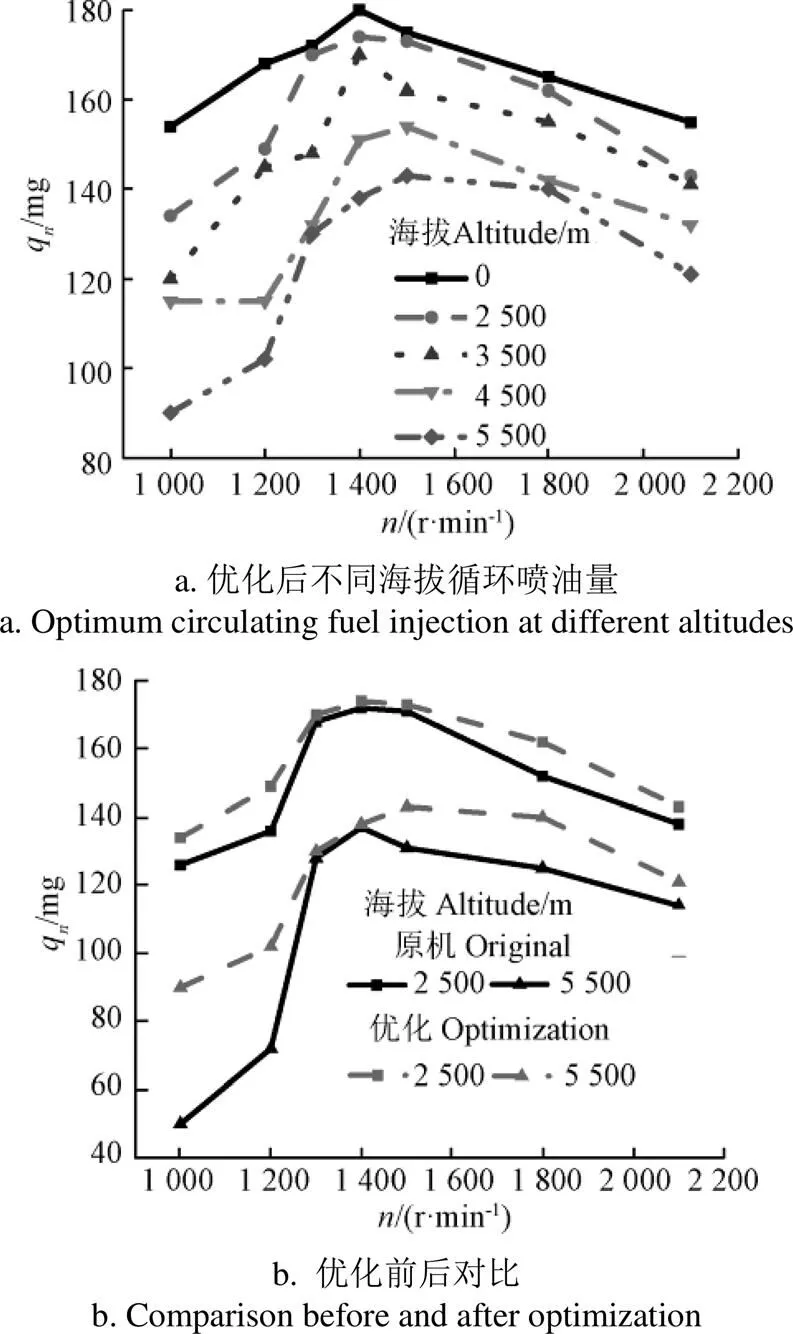

圖7a為優化后各轉速下最佳循環噴油量隨海拔變化規律。由圖可知,同一海拔條件下,柴油機最佳循環噴油量隨轉速增加先增大后減小,隨海拔升高,柴油機最佳循環噴油量逐漸減小,減小趨勢隨海拔增加逐漸遞增,由0至3 500 m不同轉速下循環噴油量平均降低了10.96%,由3 500至5 500 m平均降低了16.99%。圖7b為2 500和5 500 m條件下優化前后最佳循環噴油量對比圖。由圖可知,海拔一定時,優化后循環噴油量隨轉速的變化規律與原機基本一致,但相比原機優化后各轉速下的最佳循環噴油量都有所增加,低轉速時循環噴油量增加幅度最大,中高轉速下循環噴油量增加幅度減小,在最大轉矩轉速附近循環噴油量增加量最小,呈現出增加量自最大轉矩轉速點向兩側逐步增大的趨勢。相比于單級增壓,二級增壓增大了柴油機缸內進氣量,緩解了高原環境引起的空氣密度的下降,適當增大循環噴油量,有利于柴油機高海拔動力性能的提升,但為了保證最高燃燒壓力和排溫不超限,循環噴油量增加量需要得到限制,越靠近最大轉矩轉速點,增加值越小。

圖7 最佳循環噴油量隨轉速的變化規律

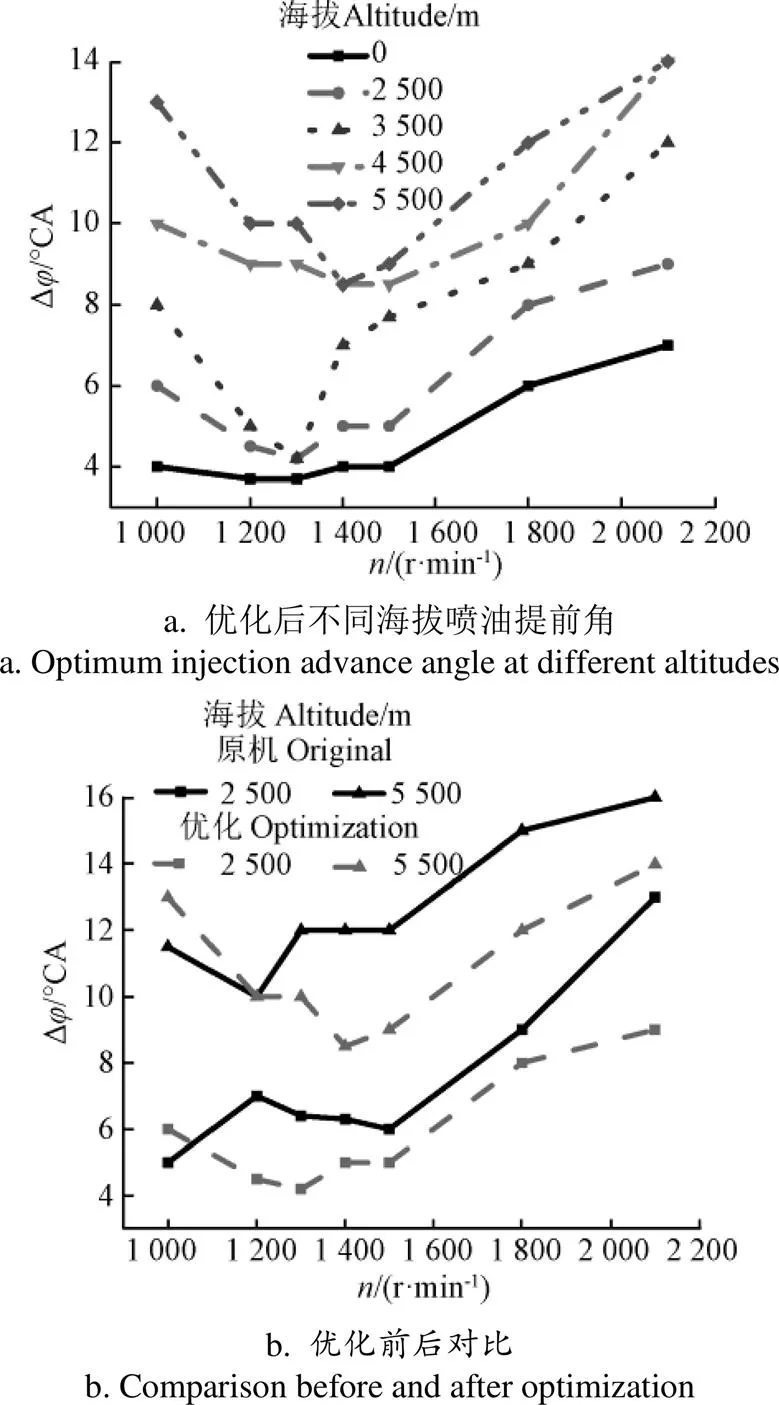

圖8為不同海拔條件下最佳噴油提前角的變化規律。由圖8a可知,同一海拔條件下,柴油機最佳噴油提前角隨轉速增加呈現先減小后增加的趨勢,最佳噴油提前角平均值隨海拔升高而增大,海拔每升高1 000 m,噴油提前角平均增大1.15 °CA。隨著海拔升高,大氣壓力與溫度降低導致進氣終了缸內空氣密度降低,反應物分子之間的碰撞概率減小,著火之前混合氣的物理和化學反應時間延長,滯燃期延長,滯燃期累積的混合氣增多,大量準備好的混合氣,幾乎同時開始燃燒,增大了速燃期內放熱速率,缸內壓力與溫度急劇上升,增加了柴油機燃燒粗暴度,因而隨海拔升高要相應增加柴油機噴油提前角[27-28]。相比于原機,優化后的噴油提前角在低速時略有增加,在海拔2 500和5 500 m,轉速在1 000~1 500 r/min時最佳噴油提前角平均分別增加了1和1.5 °CA,隨轉速升高,最佳噴油提前角減小,在2 500和5 500 m海拔下1 500~2 100 r/min平均分別減小了25.2%和17.5%,如圖8b所示。低轉速時,增壓器效率較低,增大噴油提前角有利于油氣充分混合,提高燃燒效率,進而改善柴油機低速動力、經濟性。隨著轉速增加,增壓器效率升高,相比于單級增壓器,二級增壓器增大了缸內進氣量,適當減小噴油提前角,能夠降低缸內最高燃燒壓力和燃燒粗暴度。

圖8 最佳噴油提前角隨轉速的變化規律

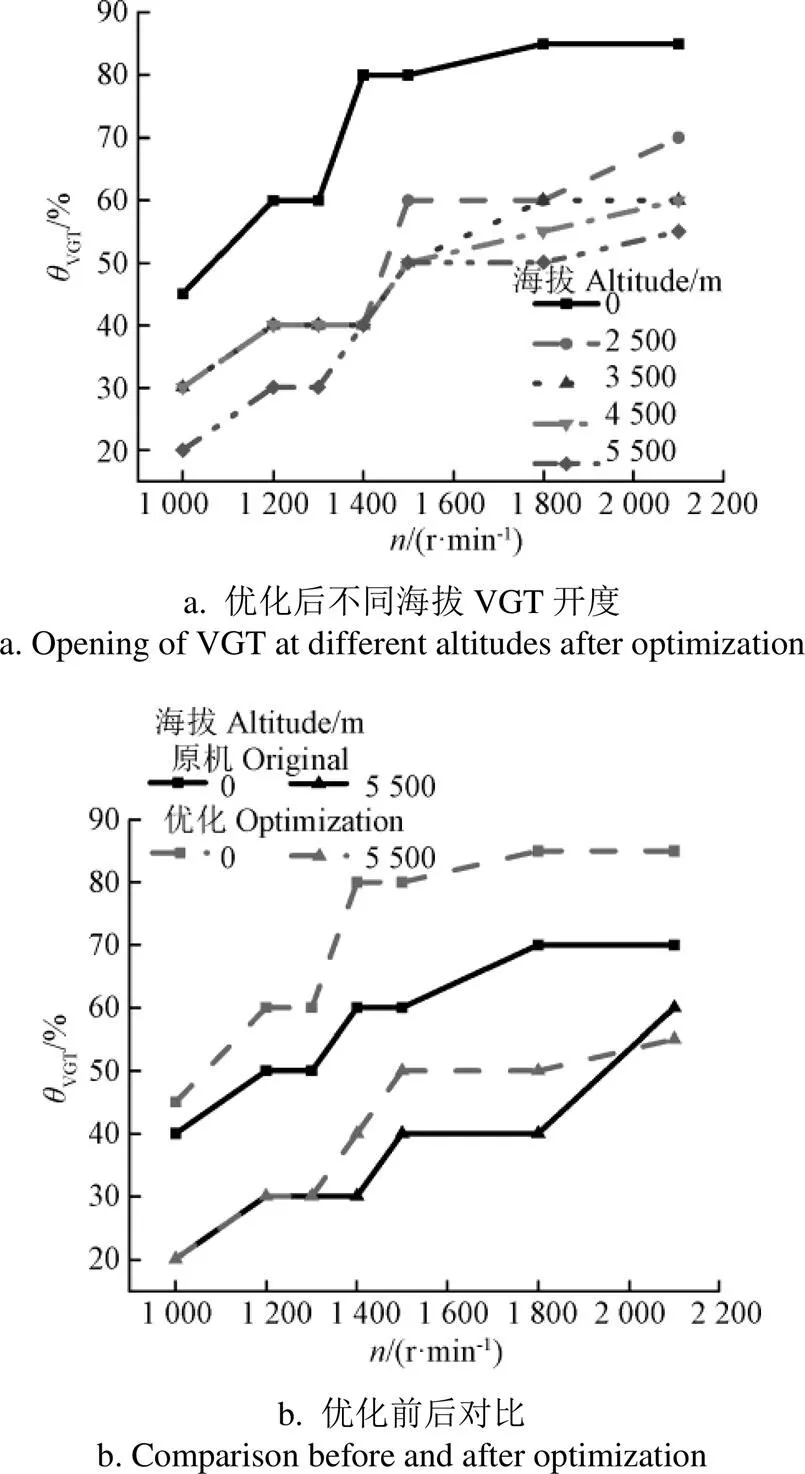

圖9a為0 m~5 500 m海拔條件下最佳VGT葉片開度隨轉速的變化規律。由圖可知,在同一海拔高度下,柴油機最佳VGT葉片開度,隨轉速的增加而逐漸增大,隨海拔升高,最佳VGT葉片開度逐漸減小,相比于平原,5 500 m海拔條件不同轉速工況下最佳VGT葉片開度平均降低了44.44%。海拔升高和轉速的降低都會導致進氣壓力降低,通過減小VGT葉片開度減少渦輪流通面積,使得排氣背壓和流速增大,可用排氣能量升高,進而提高增壓器轉速,增加柴油機進氣流量,隨著海拔降低和轉速增加,需要增大VGT開度以防止增壓器超速。由圖 9b可知,相比于原機,柴油機優化后最佳VGT開度呈現增大趨勢,但增大趨勢在不同海拔條件下有所差異。在平原條件下,優化后的VGT開度增大幅度隨轉速增加而增大,在海拔5 500 m條件下,低速時VGT葉片開度與原機相同,隨著轉速升高,VGT葉片開度增加幅度呈現先增大后減小的趨勢,在2 100 r/min時,優化后的VGT開度相比于原機略有下降。相比于單級增壓器,二級增壓器增壓比較高且隨著轉速增加效率升高,平原條件下,較大的VGT開度已經能夠滿足柴油機燃燒需求,因此優化后VGT開度增加,增大幅度隨轉速升高而增大。在海拔5 500 m條件下,低速工況下,VGT葉片開度減小,一方面減少了流通面積,提高了增壓器轉速,另一方面VGT葉片開度減少使得泵氣損失增大,減少了缸內進氣量,因此在低速下,VGT開度變化較小。在中高轉速下,增壓器效率較高,適當增大VGT開度增大渦輪流通面積,來降低排氣背壓和流速以避免增壓器超速。額定轉速工況下,原機最高燃燒壓力距離限制值仍有一定余量,減小VGT葉片開度可進一步提升柴油機額定功率[29]。

圖9 最佳VGT葉片開度隨轉速的變化規律

由以上結論可以得到不同轉速下優化前后增壓與噴油參數協同優化控制策略。0 m海拔條件下,相比于原機,優化后柴油機VGT葉片開度和噴油量增大,噴油提前角減小。主要由于0 m海拔條件下,進氣流量和過量空氣系數較大使得缸內密度增加,增大噴油量與VGT葉片開度減小噴油提前角,能夠在保證最高燃燒壓力不超限的前提下有效提升柴油機動力性。5 500 m海拔條件下,相比于原機,柴油機優化后低轉速下VGT葉片開度不變,循環噴油量和噴油提前角增大,中高轉速下VGT葉片開度和循環噴油量增大,噴油提前角減小。相比于單級增壓,柴油機匹配二級增壓后在低速條件下能夠改善渦輪增壓器的效率,在VGT葉片開度不變條件下,增大循環噴油量和噴油提前角有利于增加滯燃期內混合氣,進而提高柴油機低速時動力性能[30]。隨著轉速增加,一方面渦輪增壓器效率升高,進氣量增加明顯,柴油機增加循環噴油量,增大了混合氣濃度,有利于動力性提升,但柴油機排溫與增壓器轉速也會增加,為了防止這些超限,必須增大VGT開度,減小噴油提前角。

4 結 論

1)將仿真模型與神經網絡相結合,有效構建增壓和噴油參數與輸出轉矩之間聯系,所構建模型的預測值和仿真值之間相關度較高,能夠用于增壓與噴油參數協同優化研究。

2)相比于原機,優化后最佳循環噴油量增加,增加量呈現出自最大轉矩轉速點向兩側逐漸增大的趨勢。最佳噴油提前角,在海拔2 500和5 500 m低速時分別增加了1和1.5 °CA,隨轉速升高,最佳噴油提前角平均分別減小了25.2%和17.5%。最佳VGT開度在海拔0 m時,增大幅度隨轉速增加而增大,在海拔5 500 m時,低速時最佳VGT開度不變,中高轉速VGT增加幅度隨轉速先增大后減小。

3)通過增壓與噴油參數協同優化后,在0 m海拔條件下,VGT葉片開度和噴油量增大,噴油提前角減小。5 500 m海拔條件下,低速下VGT葉片開度不變,循環噴油量和噴油提前角增大,中高轉速下VGT葉片開度和循環噴油量增大,噴油提前角減小。

[1] 倪計民,劉越,石秀勇,等.可變噴嘴渦輪增壓及廢氣再循環系統改善柴油機排放性能[J].農業工程學報,2016,32(16):82-88. Ni Jimin, Liu Yue, Shi Xiuyong, et al. Variable nozzle turbine combined with Venturi exhaust gas recirculation system improving emission performance of diesel engines[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(16):82-88. (in Chinese with English abstract)

[2] Liu R, Zhang Z, Dong S, et al. High-altitude matching characteristics of regulated two-stage turbocharger with diesel engine[J]. Journal of Engineering for Gas Turbines and Power, 2017, 139(9):094501-094509.

[3] Jiao Y, Liu R, Zhang Z, et al. Comparison of combustion and emission characteristics of a diesel engine fueled with diesel and methanol-Fischer-Tropsch diesel-biodiesel-diesel blends at various altitudes[J]. Fuel, 2019, 224(5):52-59.

[4] 畢玉華,唐成章,申立中,等.VNT與EGR耦合對不同氣壓下燃用含氧燃料柴油機性能的影響[J].農業工程學報,2018,34(17):38-45. Bi Yuhua, Tang Chengzhang, Shen Lizhong, et al. Effect of VNT and EGR coupling on performance of diesel engine fueled with oxygenated fuel under different atmospheric pressures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17):38-45. (in Chinese with English abstract)

[5] 周廣猛,劉瑞林,焦宇飛,等. 柴油機高原燃燒特性研究進展[J]. 車用發動機,2018(4):17-21. Zhou Guangmeng, Liu Ruilin, Jiao Yufei, et al. Research progress of diesel engine combustion characteristics in plateau environment[J]. Vehicle Engine, 2018 (4):17-21. (in Chinese with English abstract)

[6] 黃粉蓮,紀威,周煒,等.車用渦輪增壓柴油機加速工況瞬態特性仿真[J].農業工程學報,2014,30(3):63-69. Huang Fenlian, Ji Wei, Zhou Wei, et al. Simulation of transient performance of vehicle turbocharged diesel engine during acceleration process[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(3):63-69. (in Chinese with English abstract)

[7] 王俊,申立中,楊永忠,等.基于響應曲面法的非道路用高壓共軌柴油機設計點優化標定[J].農業工程學報,2017,33(3):31-39. Wang Jun, Shen Lizhong, Yang Yongzhong, et al. Optimizing calibration of design points for non-road high pressure common rail diesel engine base on response surface methodology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(3):31-39. (in Chinese with English abstract)

[8] 王利民,韓義勇,裴海俊.基于多級閉環的柴油機VGT控制策略的研究[J].汽車與配件,2018(20):72-74. Wang Limin, Hang Yiyong, Pei Haijun. Research on control strategy of diesel VGT based on multi-level closed loop[J]. Automobile & Parts, 2018(20): 72-74. (in Chinese with English abstract)

[9] 唐蛟,李國祥,王志堅,等.基于歐Ⅵ柴油機EGR閥與VGT閥解耦控制策略研究[J].內燃機工程,2015,36(3):63-67. Tang Jiao, Li Guoxiang, Wang Zhijian, et al. Study of EGR/VGT decoupling control strategy based on euroⅥ diesel engines[J]. Chinese Internal Combustion Engine Engineering, 2015, 36(3): 63-67. (in Chinese with English abstract)

[10] 朱振夏. 增壓柴油機高原環境下的供油與進氣調節研究[D].北京:北京理工大學,2015. Zhu Zhenxia. Investigation on Parameters Adjustment of Fuel Supplying and Air-Intaking Systems for Diesel Engines Working at Plateau Environment[D]. Beijing: Beijing Institute of Technology, 2015. (in Chinese with English abstract)

[11] 董素榮,劉瑞林,周廣猛,等. VGT葉片開度對二級增壓柴油機高海拔燃燒特性與性能的影響[J]. 內燃機學報,2017,35(3): 231-237. Dong Surong, Liu Ruilin, Zhou Guangmeng, et al. Effects of VGT blade opening on combustion and performance on a two-stage turbocharging diesel engine at high altitude[J].Transactions of CSICE, 2017, 35 (3):231-237. (in Chinese with English abstract)

[12] 陳貴升,陳春林,狄磊,等.可變二級增壓柴油機變海拔工作特性數值模擬[J].內燃機學報,2018,36(4):305-313. Chen Guisheng, Chen Chunlin, Di Lei, et al. Numerical simulation on performance of diesel engine equipped with regulated two stage turbocharging systems at different altitudes[J]. Transactions of CSICE, 2018, 36 (4):305-313. (in Chinese with English abstract)

[13] 徐思友,潘麗麗,楊磊,等.二級增壓系統不同旁通結構流阻特性仿真分析[J].車用發動機,2017(4):68-72. Xu Siyou, Pan Lili, Yang Lei, et al. Simulation on flow resistance characteristics of different bypass structures for two-stage turbocharger[J]. Vehicle Engine, 2017(4):68-72. (in Chinese with English abstract)

[14] 董素榮,劉卓學,熊春友,等.二級可調增壓共軌柴油機的高海拔燃燒特性[J].燃燒科學與技術,2017,23(1):36-40. Dong Surong, Liu Zhuoxue, Xiong Chunyou, et al. High altitude combustion characteristics of common rail diesel engine with two-stage regulated turbocharging system[J]. Journal of Combustion Science and Technology, 2017, 23(1):36-40. (in Chinese with English abstract)

[15] 騰鵬坤. 噴油與供氣策略對二級增壓柴油機瞬變性能的影響[D].長春:吉林大學,2017. Teng Pengkun. The Influence of Injection and Intake Parameters On the Two-Stage Turbocharges Diesel Engine Under Transient Operations[D]. Changchun: Jilin University, 2017. (in Chinese with English abstract)

[16] 袁興.復合EGR對二級增壓柴油機瞬變性能的影響[D].長春:吉林大學,2018. Yuanxing. Effect of Hybrid EGR on Transient Performance of a Two-Stage Turbocharged Diesel Engine[D].Changchun: Jilin University, 2018. (in Chinese with English abstract)

[17] 李長江. 柴油機高原可調二級增壓系統的匹配與調節[D].北京:北京理工大學,2016. Li Changjiang. The Study of Matching and Adjusting of Regulated Two-Stage Turbocharging System for Diesel Working at Plateau[D].Beijing: Beijing Institute of Technology, 2016. (in Chinese with English abstract)

[18] Hiroyasu H, Arai M. Structure of Fuel Sprays in Diesel Engine[C]// Society of Automotive Engineers: International Congress & Exposition. Detroit: SAE International in United States, 1990.

[19] Woschni G.A applicable equation for the instantaneous heat transfer coefficient in the internal combustion engine[C] // Society of Automotive Engineers: National Fuels and Lubricant &Transportation Meetings. Detroit: SAE International in United States, 1967.

[20] 王明露. 國Ⅴ共軌柴油機逐點模型標定研究[D].秦皇島:燕山大學,2017. Wang Minglu. Study on Point by Point Model Base Calibration for CN V Common Rail Diesel Engine[D]. Qinhuangdao: Yanshan University, 2017. (in Chinese with English abstract)

[21] 周廣猛. 高壓共軌柴油機高海拔標定和燃燒過程研究[D].武漢:海軍工程大學,2012. Zhou Guangmeng. Research on High Altitude Calibration and Combustion Process of Common Rail Diesel Engine[D]. Wuhan: Naval University of Engineering, 2012. (in Chinese with English abstract)

[22] 牛曉曉,王賀春,李旭,等.基于神經網絡的柴油機性能預測模型優化[J].內燃機學報,2018,36(6):561-568. Niu Xiaoxiao, Wang Hechun, Li Xu, et al. Optimization of diesel engine responses prediction model based on neural network[J].Transactions of CSICE, 2018, 36 (6):561-568. (in Chinese with English abstract)

[23] 王森,趙金星,劉雙寨,等.基于神經網絡和遺傳算法的Atkinson循環發動機幾何壓縮比優化[J].內燃機學報,2015,33(4):370-377. Wang Sen, Zhao Jinxing, Liu Shuangzhai, et al. Optimization of geometrical compression ratio for an atkinson cycle engine based on artificial neural network and genetic algorithm[J]. Transactions of CSICE, 2015, 33 (4):370-377. (in Chinese with English abstract)

[24] 朱振夏,張付軍,吳滔滔,等.基于神經網絡的零維預測燃燒模型及建模方法[J].內燃機學報,2015,33(2):163-170. Zhu Zhenxia, Zhang Fujun, Wu Taotao, et al. Zero-D predictable combustion model based on neural network and modeling[J]. Transactions of CSICE, 2015, 33 (2):163-170. (in Chinese with English abstract)

[25] Meng X, Jia M, Wang T. Neural network prediction of biodiesel kinematic viscosity at 313 K[J]. Fuel, 2014, 121:133-140.

[26] Wu B, Filipi Z, Kramer D, et al. Using neural networks to compensate altitude effects on the air flow rate in variable valve timing engines[C]// Society of Automotive Engineers: SAE 2005 World Congress & Exhibition. Detroit: SAE International in United States, 2005.

[27] 王憲成,郭猛超,和穆,等.高原環境大功率柴油機性能綜合改進技術研究[J].內燃機工程,2014,35(2):113-118. Wang Xiancheng, Guo Mengchao He Mu, et al. Study on improvement of high power diesel engine performance in plateau environment[J]. Chinese Internal Combustion Engine Engineering, 2014, 35(2): 113-118. (in Chinese with English abstract)

[28] 劉瑞林.柴油機高原環境適應性研究[M].北京:北京理工大學出版社,2013:151-159.

[29] 鄒澤宇. 不同增壓系統對重型柴油機性能和排放影響的試驗研究[D].天津:天津大學,2017. Zhou Zeyu. Effect of Different Turbocharging Systems on Performance and Emissions of a Heavy-duty Diesel Engine[D].Tianjin: Tianjin University, 2017. (in Chinese with English abstract)

[30] 楊春浩,劉瑞林,張眾杰,等.基于VGT控制參數的柴油機低速變海拔熱平衡試驗[J].熱科學與技術,2019,18(3):206-213. Yang Chunhao, Liu Ruilin, Zhang Zhongjie, et al. Exper imental study on thermal balance of diesel engine at low speed affected by VGT control parameters at variable altitudes[J]. Journal of Thermal Science and Technology, 2019, 18(3): 206-213. (in Chinese with English abstract)

Optimization of supercharger and injection parameters for diesel engine at plateau environment

Jiao Yufei1, Liu Ruilin2※, Zhang Zhongjie1, Zhou Guangmeng2, Yang Chunhao3, Ma Jiaming1

(1.,,300161,; 2.,,300161,; 3.,,430033,)

Supercharge and fuel injection are direct factors to improve the performance of diesel engines at plateau. When diesel engines are used at higher altitudes, especially in the Qinghai-Tibet plateau region with the altitude ranging from 3000 to 5000 m, the decreasing ambient pressure and temperature reduce the air inflow resulting in deteriorating combustion, reducing power output, increasing fuel consumption, worsening emissions, exceeding cylinder pressure, cylinder pressure, thermal load and turbocharger speed limits. The optimization of injection parameters can improve the plateau combustion process of diesel engine to some extent, however, optimization of injection parameters alone cannot fundamentally solve the problem of insufficient intake and power decline of diesel engines at plateau. Two-stage variable geometry turbocharge (VGT) system is an effective way to increase the intake pressure effectively. However, only optimizing the control parameters of the supercharging system without adjusting the injection parameters will lead to the problem of "improper oil and gas coordination" at high altitude, and the plateau application potential of the two-stage variable geometry turbocharge system cannot be fully play. Recent researches mainly focused on optimizing injection parameters or two-stage variable geometry turbocharge system, there was few about the comprehensive optimization of supercharger and injection parameters, therefore, the paper focused on optimizing the compositive control strategy of supercharge and injection parameters. In the paper, a GT-Power model of a two-stage variable geometry turbocharged (VGT) diesel engine was built and verified by experiment on engine plateau environment simulating testing bed. The simulation performance date of the engine was obtained from the model. What’s more, the neural network was established and then trained with these simulation values to improve the power performance of the engine, and finally the optimization rules and comprehensive control strategy of supercharge and injection parameters were obtained. The results showed that: The optimized circulating fuel injection quantity had similar variation trend with the original parameters. What was different was that the circulating fuel injection quantity increased after optimizing, the increment came to its maximum at lower speed and its minimum at speed of maximum torque, and it showed a trend that the increment quantity gradually increased from the speed point of the maximum torque to both sides. With the increase of altitude, the optimal cycle fuel injection quantity of the engine decreased gradually, and the decreasing trend increased gradually with altitude increasing. The circulating fuel injection quantity decreased by 10.96% on average from 0 to 3500 m, and by 16.99% on average from 3500 to 5500 m. At a certain altitude, the optimal injection advance angle of the engine decreased first and then increased with the increase of speed, and the average value of the optimal injection advance angle increased with altitude increasing. Compared with the original parameters, the optimum injection advance angle increased by 1 and 1.5℃A, respectively, at low speed conditions of 2500 and 5500 m, however, when it came to higher speed, the optimum injection advance angle decreased by 25.2% and 17.5%, respectively. The optimum VGT opening increased large gradually with the increase of the speed at 0 m, while when it came to 5500 m, it kept invariable at lower speed, and increased firstly and then decreased at higher speed. After comprehensive optimizing of supercharge and fuel injection, the VGT opening and circulating fuel injection quantity increased and the injection advance angle decreased at 0 m. When it came to low speed of 5500 m, the VGT opening kept invariable, the circulating fuel injection quantity and injection advance angle increased, however, the VGT opening and circulating fuel injection quantity increased, the injection advance angle decreased at high speed.

diesel engine; optimization; high altitudes; two-stage variable geometry turbocharged system; injection parameters

2019-05-05

2019-08-28

國防預研資助項目(30105190501)

焦宇飛,博士生,主要研究方向含氧燃料高原環境適應性。Email:jiaoyufei2016@163.com

劉瑞林,教授,博士生導師,主要從事內燃機高原環境適應性研究。Email:163lrl@163.com

10.11975/j.issn.1002-6819.2019.17.009

TK427

A

1002-6819(2019)-17-0066-08

焦宇飛,劉瑞林,張眾杰,周廣猛,楊春浩,馬家明.高原環境條件下柴油機增壓與噴油參數協同優化[J]. 農業工程學報,2019,35(17):66-73. doi:10.11975/j.issn.1002-6819.2019.17.009 http://www.tcsae.org

Jiao Yufei, Liu Ruilin, Zhang Zhongjie, Zhou Guangmeng, Yang Chunhao, Ma Jiaming. Optimization of supercharger and injection parameters for diesel engine at plateau environment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(17): 66-73. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.17.009 http://www.tcsae.org