聲發射技術應用于碳纖維板復合材料損傷檢測研究

曹玉祥 安璐 李志強 容禹

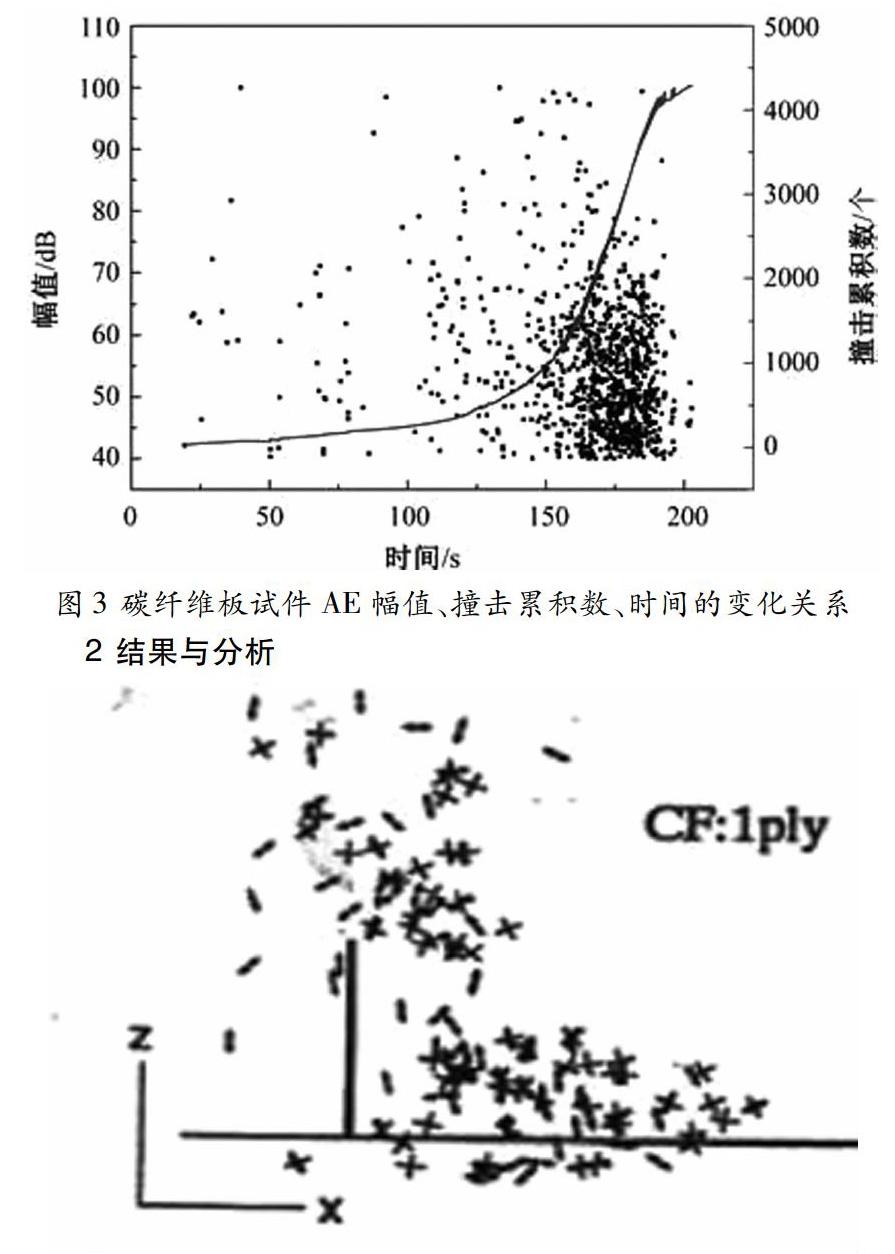

摘 要:聲發射(Acoustic Emission簡稱“AE”),是材料變形或破壞時積蓄起來的應變能所釋放聲音能量的傳播現象。大量的聲發射信號,會產生在碳纖維復合材料拉伸損傷過程中。本文通過對聲發射(AE)信號的數據進行分析,研究碳纖維復合材料的損傷演變規律;對于碳纖維復合材料之細微變形及應變能的變化,聲發射(AE)技術可以比傳統百分表、應變儀技術能夠超前檢測出來,因此聲發射(AE)技術看成為預測、分析碳纖維復合材料中動態構造變化的實用方法。將聲發射(AE)技術應用于碳纖維板(CFRP)復合材料的使用狀態動態監測中,可以在抗震防災及工程結構安全可靠度領域中應用國際先進的工程結構使用壽命健康檢測體系,使得抗震防災及工程結構安全可靠度領域中大量房屋、橋梁、邊坡、地下工程等重要工程結構的系統性安全產生科學有效的保障效應。

關鍵詞:聲發射;碳纖維復合材料;工程結構使用壽命

Abstract:Acoustic Emission(AEousion for short)is a propagation phenomenon of sound energy released by strain energy accumulated when materials are deformed or destroyed.A large number of acoustic emission signals will be generated during the carbon fiber composite tensile damage.In this paper,by analyzing the data of acoustic emission(AE)signals,the damage evolution law of carbon fiber composites is studied.For the fine deformation of carbon fiber composites and the change of strain energy,acoustic emission(AE)technology can be compared with traditional dial gauges and strains.Instrument technology can be detected in advance,so acoustic emission(AE)technology is seen as a practical method for predicting and analyzing dynamic structural changes in carbon fiber composite materials.Applying Acoustic Emission(AE)technology to the dynamic monitoring of the use status of CFRP composite materials,it can apply the international advanced engineering structure life and health detection system in the fields of earthquake resistance and disaster prevention and engineering structure safety and reliability,making the earthquake resistant The systematic safety of a large number of important engineering structures such as houses,bridges,slopes,and underground engineering in the field of disaster prevention and engineering structure safety and reliability has produced scientific and effective guarantee effects.

Key words:acoustic emission;carbon fiber composite materials;service life of engineering structures

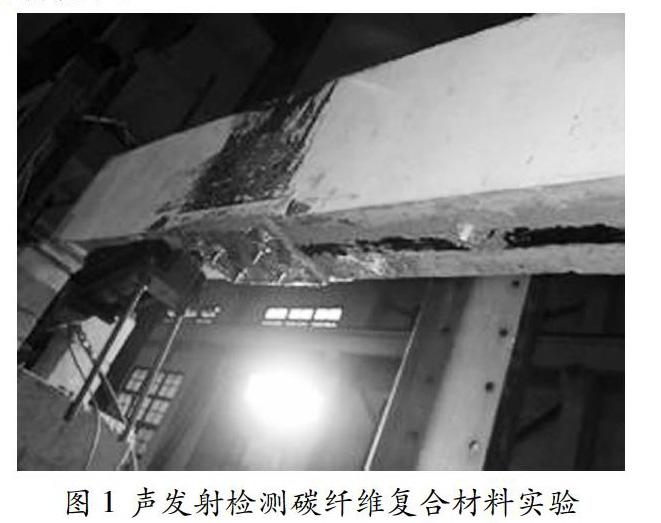

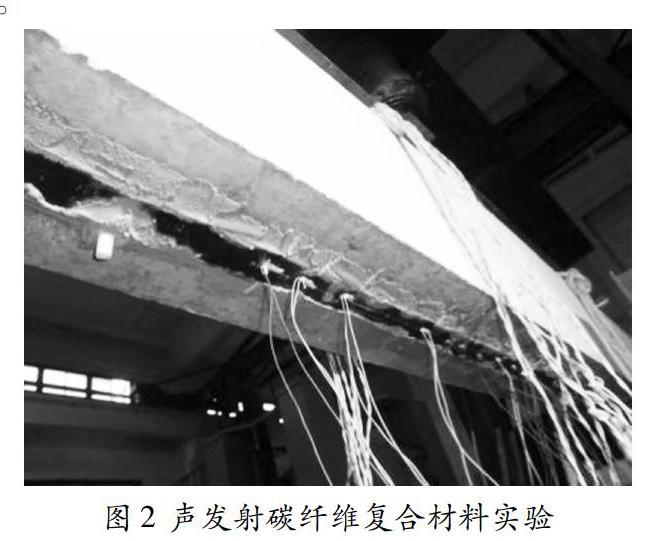

目前,聲發射檢測是碳纖維復合材料的損傷檢測主要方法之一,聲發射檢測,是一種在碳纖維復合材料的損傷檢測領域有待開發的被動檢測方式。聲發射檢測利用材料在局部受力作用下,產生能量快速釋放而發出瞬態彈性波的特征,配之以彈性波記錄的分析,揭示材料內部在外界載荷作用下產生的變形、裂紋形成以及裂紋的擴展、斷裂等現象。由于可以在線實時監測,不影響設備的運行,也不受材料加工形狀及表面結構的影響,聲發射檢測技術因此成為了復合材料損傷分析中一種重要的分析技術。……