基于三參數雙τ2強度理論的厚壁圓筒極限壓力分析*

陳四利, 李艷宇, 張精禹

(沈陽工業大學 建筑與土木工程學院, 沈陽 110870)

?

基于三參數雙τ2強度理論的厚壁圓筒極限壓力分析*

陳四利, 李艷宇, 張精禹

(沈陽工業大學 建筑與土木工程學院, 沈陽 110870)

為了得到均布載荷作用下拉壓同性材料與拉壓異性材料厚壁圓筒彈塑性分析全過程的統一解析解,采用三參數雙τ2強度理論對厚壁圓筒進行彈塑性應力分析.通過引用三參數雙τ2強度理論中的極限應力比α與β對拉壓同性材料和拉壓異性材料進行了統一分析,分別得到了彈性極限壓力、彈塑性極限壓力以及彈塑性區應力與材料的極限應力比和彈塑性半徑的關系式.結果表明,不僅材料的極限應力σt、極限應力比α和β對厚壁圓筒的極限承載能力有影響,而且厚壁圓筒的內、外半徑亦與厚壁圓筒的極限壓力有關.

均布載荷; 解析解; 厚壁圓筒; 極限應力比; 彈塑性應力; 彈性極限壓力; 彈塑性極限壓力

Tresca強度理論和Mises屈服準則只適用于拉壓同性材料,而在實際工程中,大部分材料均屬于拉壓異性材料,因此,采用Tresca強度理論和Mises屈服準則對這類材料進行彈塑性分析將產生較大誤差.近年來,對于拉壓異性材料厚壁圓筒或厚壁圓環的彈塑性分析引起眾多學者的廣泛關注,并且取得了良好的進展[1-5].1990年統一強度理論提出之后,楊宇宙[6-7]、敖文剛[8]均采用雙剪統一理論進行了厚壁圓筒極限載荷統一解的分析,不同之處在于其充分考慮了中間主應力σ2對材料的影響.本文采用三參數雙τ2強度理論對厚壁圓筒進行極限壓力分析,在考慮中間主應力對材料的影響以及材料極限拉壓比不同的基礎上,充分思量了不同材料的剪拉比不同的特點,使其更好地適用于不同材料的極限應力分析.

1 三參數雙τ2強度理論

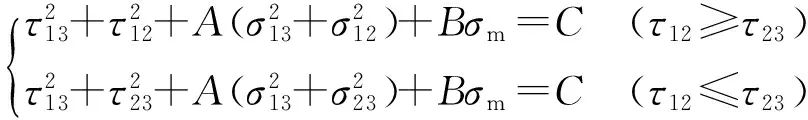

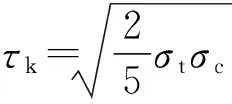

(1)

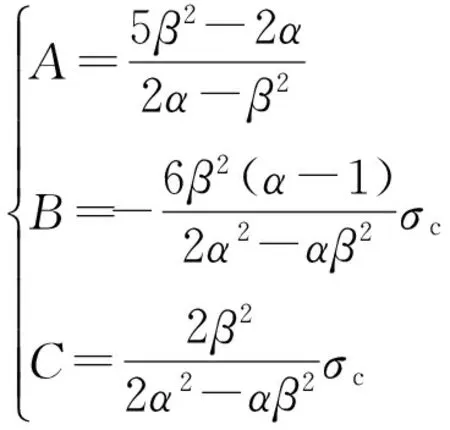

假設3種極限應力狀態分別為單軸拉伸應力狀態、單軸壓縮應力狀態以及純剪切應力狀態.設單軸壓縮極限應力為σc,單軸拉伸極限應力為σt,剪切極限應力為τk,將3種極限應力表示3個主應力,并引入極限應力比α和β,其中,α=σc/σt,β=τk/σt,分別代入式(1)可求得3個參數的表達式,即

(2)

將式(2)及主剪應力和平均應力表達式代入式(1),可得新的三參數雙τ2強度理論表達式,即

(3)

2 厚壁圓筒的極限壓力分析

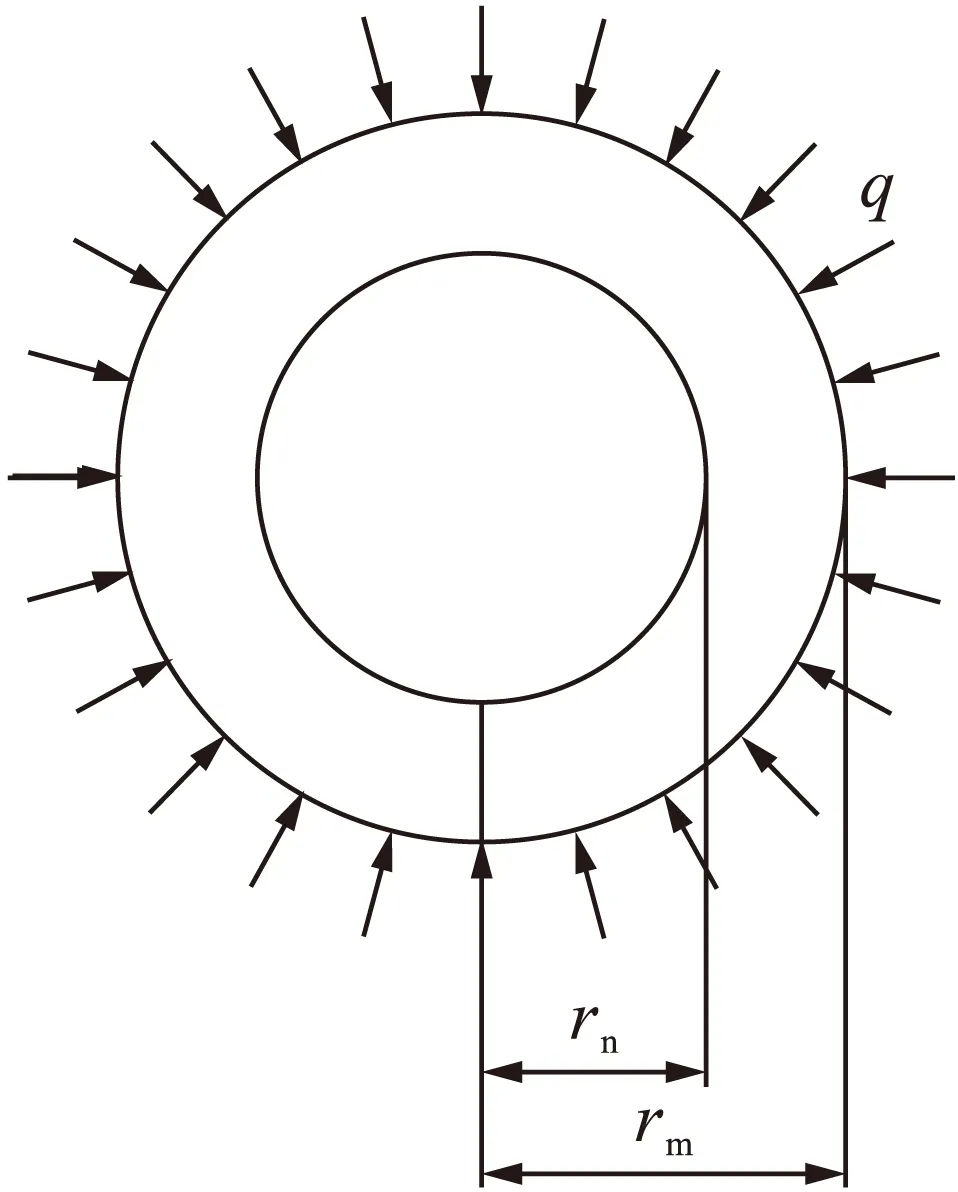

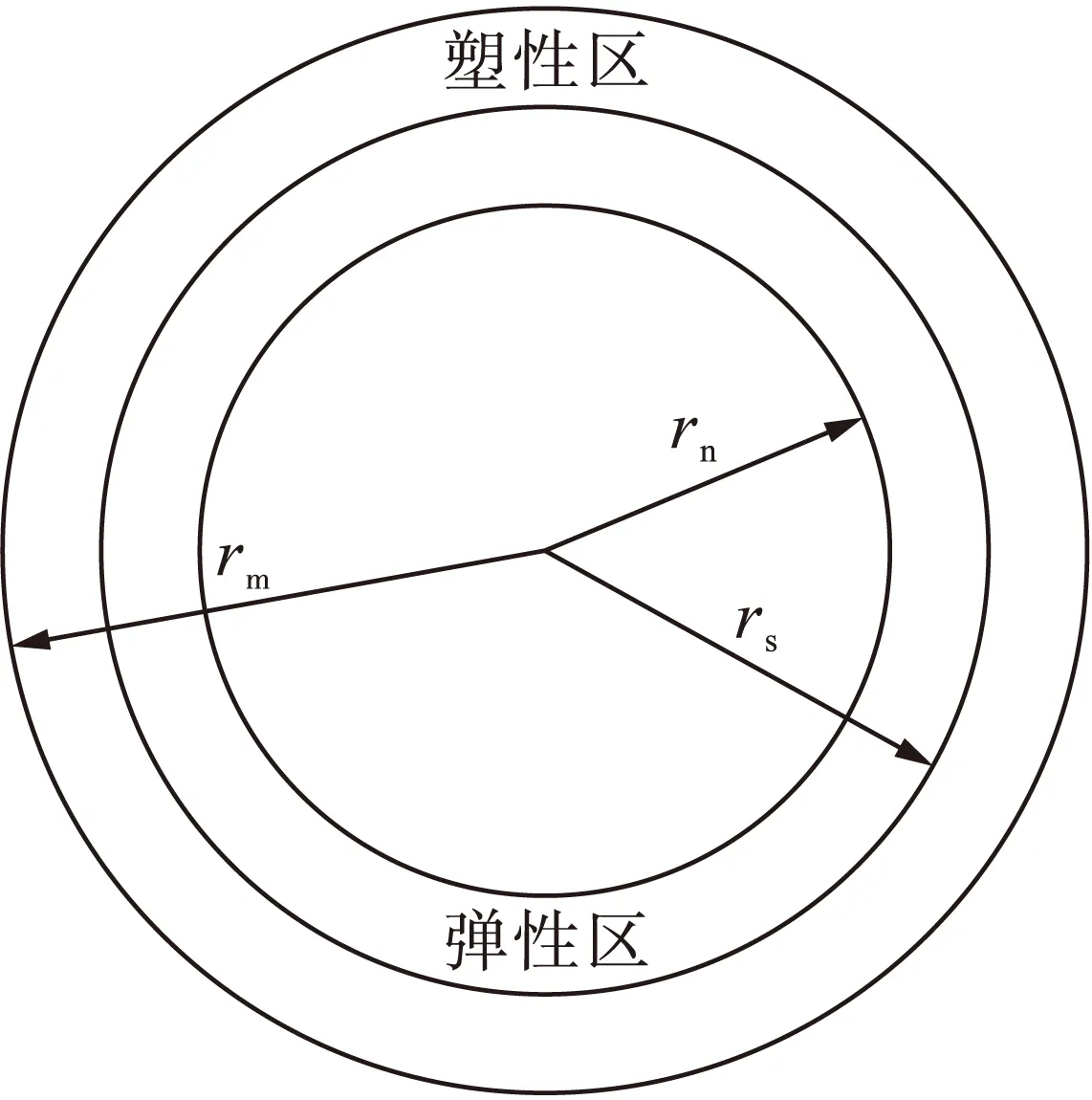

圖1為厚壁圓筒模型.某受均布荷載作用下的厚壁圓筒,外半徑為rm,內半徑為rn,其受均布荷載為q,假設材料為理想塑性不可壓縮,對此圓筒進行極限壓力分析.

2.1彈性狀態

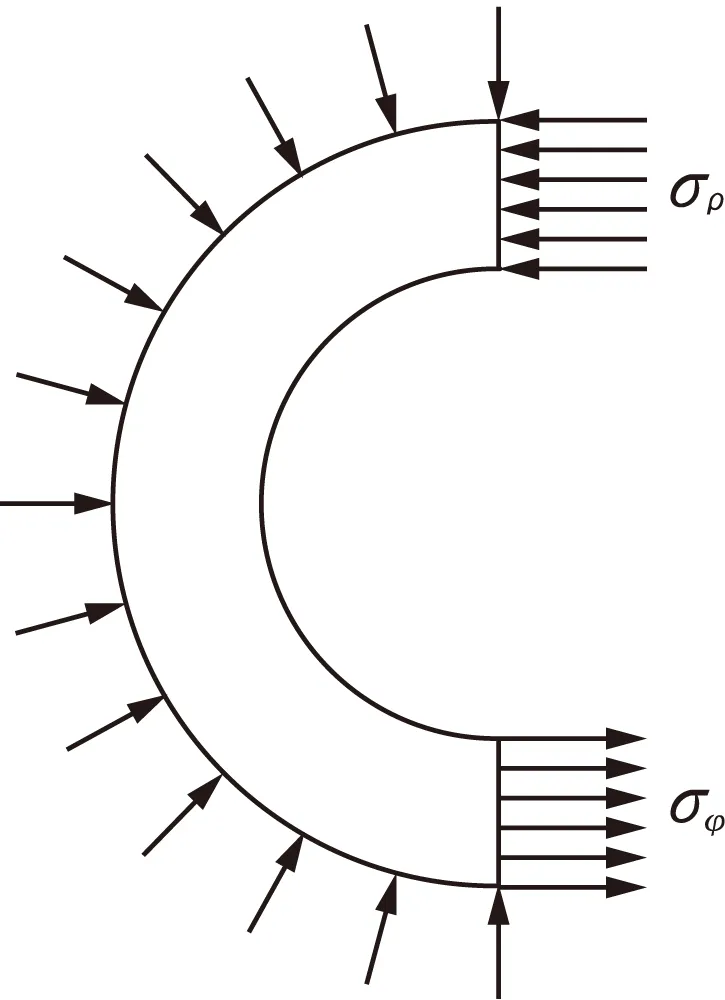

由于外壓為正,則徑向正應力σρ為壓應力,環向正應力σφ為拉應力,應力分布大致如圖2所示.

圖1 厚壁圓筒模型Fig.1 Model for thick-wall cylinder

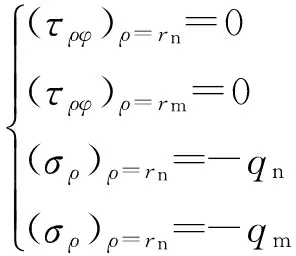

根據徐芝綸[12]的彈性力學解答可知其邊界條件為

圖2 應力分布Fig.2 Stress distribution

(4)

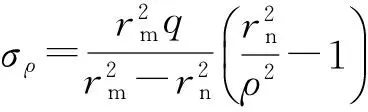

式中,ρ為厚壁圓筒的徑向半徑.進一步可求得在外壓作用下其彈性解為

(5)

(6)

根據平面應變狀態即εz=0可得

(7)

取μ=0.5,則式(7)可整理為

(8)

由式(4)~(6)可知

σ1=σφ≥σ2=σz≥σ3=σρ

(9)

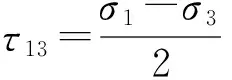

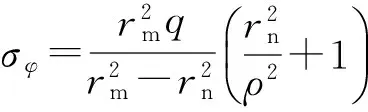

將式(9)分別代入主剪應力的公式可得

(10)

將式(10)代入式(1)中的第一式整理可得

(11)

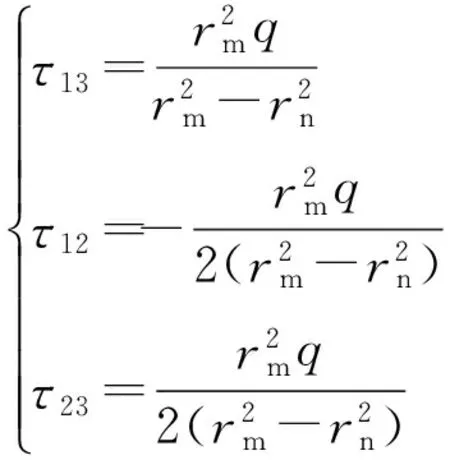

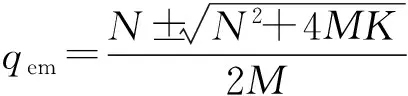

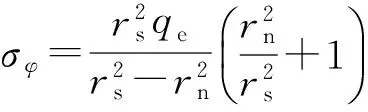

則彈性極限載荷為

(12)

式中:

應用統一強度理論求得的彈性極限載荷為

(13)

式中,b為反映中間主應力效應的參數.

2.2塑性區

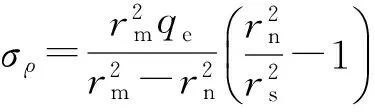

隨著均布載荷的繼續增加,當均布載荷大于圓筒所能承受的彈性極限載荷,即q>qem時,圓筒的外壁將發生塑性變形,內壁附近仍然為彈性變形,且隨著q的繼續增加,塑性區將不斷擴展,其模型如圖3所示.

圖3 彈塑性分析模型Fig.3 Elastic plastic analysis model

假定彈塑性區的半徑為rs,將圓筒的彈性區和塑性區近似認為是兩個圓筒,此時的外壓為qa,rn≤r≤rs為彈性區,rs≤r≤rm為塑性區.在塑性區范圍內應同時滿足兩個條件,分別為屈服條件與平衡方程,其平衡方程為

(14)

(15)

將式(15)代入式(14)中可得

(16)

根據邊界條件

(17)

可解得其塑性區的應力為

(18)

而在彈性區rn≤r≤rs,應滿足邊界條件

(19)

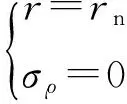

且在r=rs處符合連續性條件,在r=rs處材料剛好發生屈服,計算可得彈性區的應力為

(20)

(21)

其中,將ρ=r=rs代入式(11)、(12),可得到qe,qe為應用本文理論求得的彈性極限載荷.

(22)

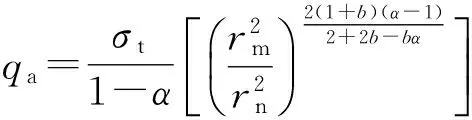

隨著q的不斷增大,塑性區不斷向內擴展,當ρ=r=rn時,整個厚壁圓筒將全部處于塑性狀態,此時,又稱為全塑性狀態.將r=rn代入式(22),可得到塑性極限載荷,即

(23)

應用統一強度理論求得的彈性極限載荷為

(24)

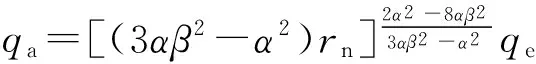

對于拉壓同性材料其塑性極限載荷為

(25)

3 結 論

本文應用已提出的三參數雙τ2強度理論對受均布外載荷作用下的厚壁圓筒進行了極限壓力分析,得到其變形全過程的解析解,其結論如下:

1) 對拉壓同性材料與拉壓異性材料的厚壁圓筒進行了分析,得到了一個統一的理論表達式;

2) 通過引用的極限應力比α與β可知,厚壁圓筒的極限承載能力不僅與材料的拉伸強度有關,材料的極限壓拉比α以及極限剪拉比β亦對其極限承載能力有一定影響;

3) 厚壁圓筒的極限承載能力與厚壁圓筒的半徑有關,且給定不同材料的σt、極限應力比α與β即可得到不同材料的厚壁圓筒的極限壓力.

[1]陳勇軍,鄭津洋,鄧貴德,等.單層厚壁圓筒彈性動應力的簡化計算方法 [J].工程力學,2006,23(11):45-51.

(CHEN Yong-jun,ZHENG Jin-yang,DENG Gui-de,et al.A simplified method for calculation elastodynamic stresses of monobloc thick-walled cylinder [J].Engineering Mechanics,2006,23(11):45-51.)

[2]朱國民,蔡鋼思,高增梁,等.厚壁圓筒在內壓和軸向力復合載荷作用下的極限載荷 [J].壓力容器,2008,25(7):1-5.

(ZHU Guo-min,CAI Gang-si,GAO Zeng-liang,et al.Limit load solution for a thick-walled cylinder under cambined internal pressure and axial tension [J].Pressure Vessel Technology,2008,25(7):1-5.)

[3]陳昌富,肖淑君,楊宇.考慮應變軟化厚壁圓筒受外壓作用統一極限解 [J].湖南大學學報(自然科學版),2006,33(2):1-5.

(CHEN Chang-fu,XIAO Shu-jun,YANG Yu.Unified limit solution of thick wall cylinder subject to external pressure considering strain softening [J].Journal of Hunan University(Natural Sciences),2006,33(2):1-5.)

[4]Zhu X K,Leis B N.Average shear stress yield criterion and its application to plastic collapse analysis of pipelines [J].International Journal of Pressure Vessels and Piping,2006,83(9):663-671.

[5]Jin C W,Wang L Z,Zhang Y Q.Strength differential effect and influence of strength criterion on burst pre-ssure of thin-walled pipelines [J].Applied Mathema-tics and Mechanics,2012,33(11):1361-1370.

[6]楊宇宙,錢林方,徐亞棟,等.復合材料厚壁圓筒的疲勞損傷研究 [J].應用力學學報,2013,30(3):378-383.

(YANG Yu-zhou,QIAN Lin-fang,XU Ya-dong,et al.Fatigue failure analysis of composition material tube [J].Chinese Journal of Applied Mechanics,2013,30(3):378-383.)

[7]楊宇宙,錢林方.復合材料厚壁圓筒的損傷問題 [J].材料科學與工程學報,2012,30(2):256-262.

(YANG Yu-zhou,QIAN Lin-fang.Failure analysis of thick wall tube of carbon fiber/expoxy composite [J].Journal of Materials Science & Engineering,2012,30(2):256-262.)

[8]敖文剛,伍太賓.雙剪統一強度理論在厚壁圓筒分析中的應用 [J].模具工業,2007,33(8):28-31.

(AO Wen-gang,WU Tai-bin.Application of double-shear unified strength theory of thick-walled cylinder [J].Die and Mould Industry,2007,33(8):28-31.)

[9]寧寶寬,黃杰,陳四利,等.廣義雙τ2強度理論在土壓力計算中的應用 [J].沈陽工業大學學報,2009,31(6):708-711.

(NING Bao-kuan,HUANG Jie,CHEN Si-li,et al.General twinτ2strength theory for calculating earth pressure [J].Journal of Shenyang University of Technology,2009,31(6):708-711.)

[10]陳四利,俞秉義.雙T2和雙τ2屈服準則及其推廣 [J].力學與實踐,1994,16(5):60-62.

(CHEN Si-li,YU Bing-yi.TwinT2andτ2yield criteria and its generalization [J].Mechanics in Engineering,1994,16(5):60-62.)

[11]陳四利.雙T2強度理論及其推廣 [J].應用力學學報,1995,12(4):118-121.

(CHEN Si-li.TwinT2failure theory and its generation [J].Chinese Journal of Applied Mechanics,1995,12(4):118-121.)

[12]徐芝綸.彈性力學簡明教程 [M].北京:高等教育出版社,1985.

(XU Zhi-lun.Concise tutorial on elasticity [M].Beijing:Higher Education Press,1985.)

(責任編輯:鐘媛英文審校:尹淑英)

Limit stress analysis for thick-wall cylinder based on tri-parameter and twinτ2strength theory

CHEN Si-li, LI Yan-yu, ZHANG Jing-yu

(School of Architecture and Civil Engineering, Shenyang University of Technology, Shenyang 110870, China)

In order to obtain the unitive analytical solution of whole elastic-plastic analysis process for the thick-wall cylinder prepared by two materials with the same tensile and compressive strengths as well as the different tensile and compressive strengths under the effect of uniformly distributed load, the elastic-plastic stress analysis for the thick-wall cylinder was carried out with the tri-parameter and twinτ2strength theory. Through quoting the limit stress ratioαandβin the tri-parameter twinτ2strength theory, the uniform analysis for the materials with the same tensile and compressive strengths as well as the different tensile and compressive strengths were performed. In addition, the elastic limit pressure and elastic-plastic limit pressure as well as the relationship between the stress in the elastic and plastic zone, limit stress ratioαandβof materials and elastic-plastic radius were obtained, respectively. The results show that not only the material limit stressσt, limit stress ratioαandβhave certain influence on the ultimate bearing capacity of thick-wall cylinder, but also the limit pressure of thick-wall cylinder is associated with its inside and outside radius.

uniformly distributed load; analytical solution; thick-wall cylinder; limit stress ratio; elastic-plastic stress; elastic limit pressure; elastic-plastic limit pressure

2015-11-03.

國家自然科學基金資助項目(51279109).

陳四利(1959-),男,遼寧綏中人,教授,博士,主要從事環境巖土工程材料理論與試驗等方面的研究.

建筑工程

10.7688/j.issn.1000-1646.2016.05.14

TU 501

A

1000-1646(2016)05-0555-05

*本文已于2016-05-12 14∶01在中國知網優先數字出版. 網絡出版地址:http:∥www.cnki.net/kcms/detail/21.1189.T.20160512.1401.040.html