延續護理在支氣管哮喘患者中的應用

于 芳

(江蘇省海安縣人民醫院,江蘇南通 226600)

支氣管哮喘是一種常見慢性氣道炎癥性疾病,有較高的發病率,具有反復發作的特點,嚴重影響患者的身心健康。有研究顯示,對于支氣管哮喘患者進行管理與教育,可改善患者的臨床效果,降低復發的可能性[1]。患者在住院期間進行治療外,需在家中做好自我護理。延續護理是一種教練式的護理模式,以患者為中心延伸至家庭的護理。

1 資料與方法

1.1 一般資料

選取本院在2015年2月—2017年2月收治50例支氣管哮喘患者,將其隨機分為研究組與對照組,各25例。研究組中,男性13例,女性12例,年齡43~74歲,平均年齡(54.63±3.14)歲;對照組中,男性11例,女性14例,年齡42~76歲,平均年齡(55.32±4.12)歲;兩組患者的一般資料比較差異不顯著(P>0.05)。

1.2 方法

對照組進行常規護理,待患者病情穩定后進行健康教育,告知其注意事項;研究組給予延續性護理,具體為:(1)院內健康教育:患者在出院期間,通過講座、會談等形式對患者進行健康教育,讓患者全面了解疾病的特點,提高患者治療信心,提高自我護理能力;(2)心理護理:由于支氣管哮喘反復發作,易使患者出現焦慮、煩躁等不良情緒,因此,護理人員應主動與患者進行溝通與交流,從而提高患者治療的依從性。(3)出院護理:告知患者在生活中應遠離過敏源,應盡量食用多種維生素、蛋白質;患者應依據醫囑進行服藥;可經微信或電話進行隨訪,隨訪中護士應耐心的解答患者與家屬的相關問題;并告知患者定期進行復診。

1.3 觀察指標

(1)分析兩組患者的哮喘控制情況,具體使用哮喘控制測量表進行評價[2],其總分為25分,哮喘控制情況與分值成正比。(2)分析兩組患者的治療依從性,根據我院自制的治療依從性量表進行分析,總分為20分,分值越高,依從性越好。

1.4 統計學分析

采用SPSS 19.0進行分析,患者的哮喘控制情況與治療依從性以均數±標準差表示,采用t檢驗,以P<0.05為差異顯著。

2 結果

2.1 分析兩組患者的哮喘控制情況

護理前,兩組的哮喘控制評分比較無差異,護理后研究組的哮喘控制評分改善情況明顯好于對照組(P< 0.05),見表 1。

表1 兩組患者的哮喘控制情況(分,x±s)

2.2 分析兩組患者的治療依從性

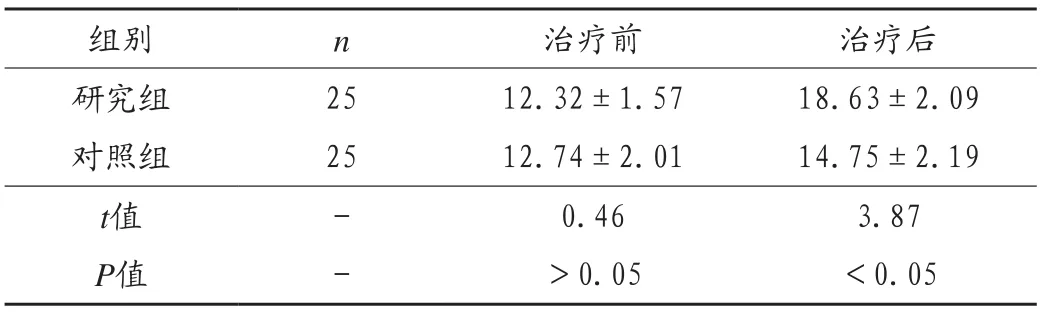

治療前,兩組的治療依從性比較無差異,治療后,研究組的治療依從性明顯高于對照組(P<0.05),詳情見表2。

表2 兩組患者的治療依從性(分,x±s)

3 討論與結論

支氣管哮喘因多種因素引發,易反復發作,患者需反復就診,因此,患者在延緩期應及時給予科學的護理與治療,可改善患者的臨床效果[3]。延續性護理是一種管教式的護理,可經電話的方式實現,建立以患者健康為目的的護理模式,通過電話或微信的方式隨訪,可了解患者的心理狀況,提醒患者及時按照醫囑服藥,以防發生因服藥不當而出現不良反應;提高患者服藥的依從性,及時解答患者對于疾病的有關凝問,并幫助患者建立治療疾病的信心,使其早日康復[4]。本研究結果顯示:護理前兩組的哮喘控制評分比較無差異,護理后研究組的哮喘控制評分改善情況明顯好于對照組,組間比較差異顯著(P<0.05);治療前,兩組的治療依從性比較無差異,治療后研究組的治療依從性明顯高于對照組(P<0.05),可知,對于支氣管哮喘患者進行延續性護理,可提高患者的哮喘控制情況與治療依從性,使其盡快康復。

[1] 余強,王冬華,劉東玲.支氣管哮喘患者延續護理的研究進展[J].中國護理管理,2015,15(6):762-765.

[2] 王旭.延續性護理模式在支氣管哮喘患者中的應用效果觀察[J].臨床醫學研究與實踐,2016,1(17):155.

[3] 陳蕾.探討延續護理對支氣管哮喘患者生活質量及疾病控制的影響 [J].中國繼續醫學教育,2016,8(36):168-170.

[4] 崔云輝,邢丹,秦巍,等.延續護理對支氣管哮喘患者肺功能及生活質量的影響[J].臨床合理用藥雜志,2017,10(15):129-131.