基于粒子群與遺傳算法的排序區(qū)揀選優(yōu)化研究

張巖

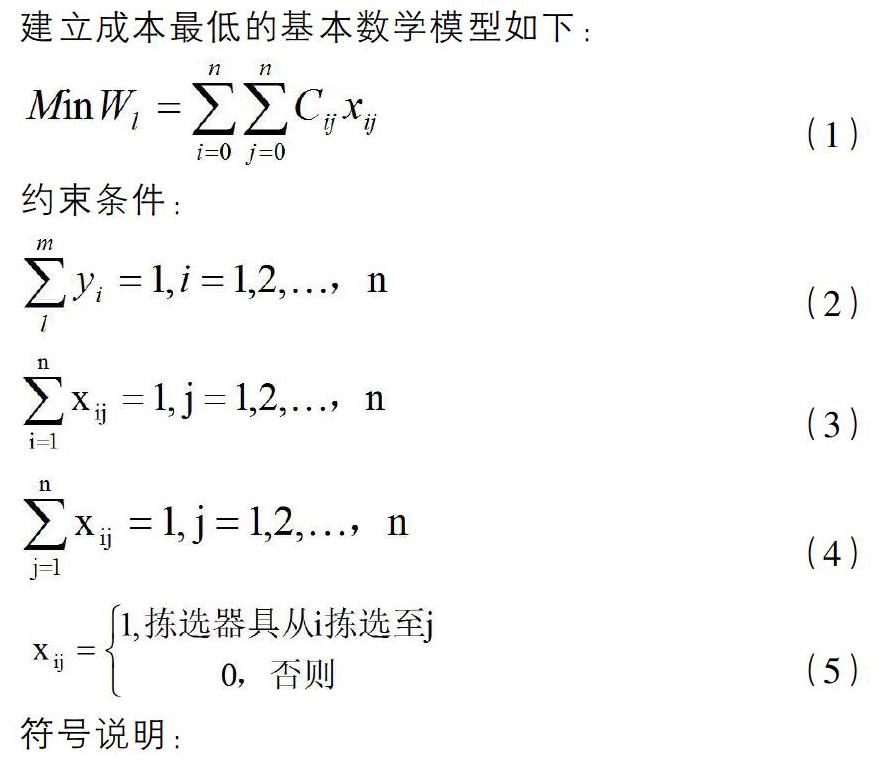

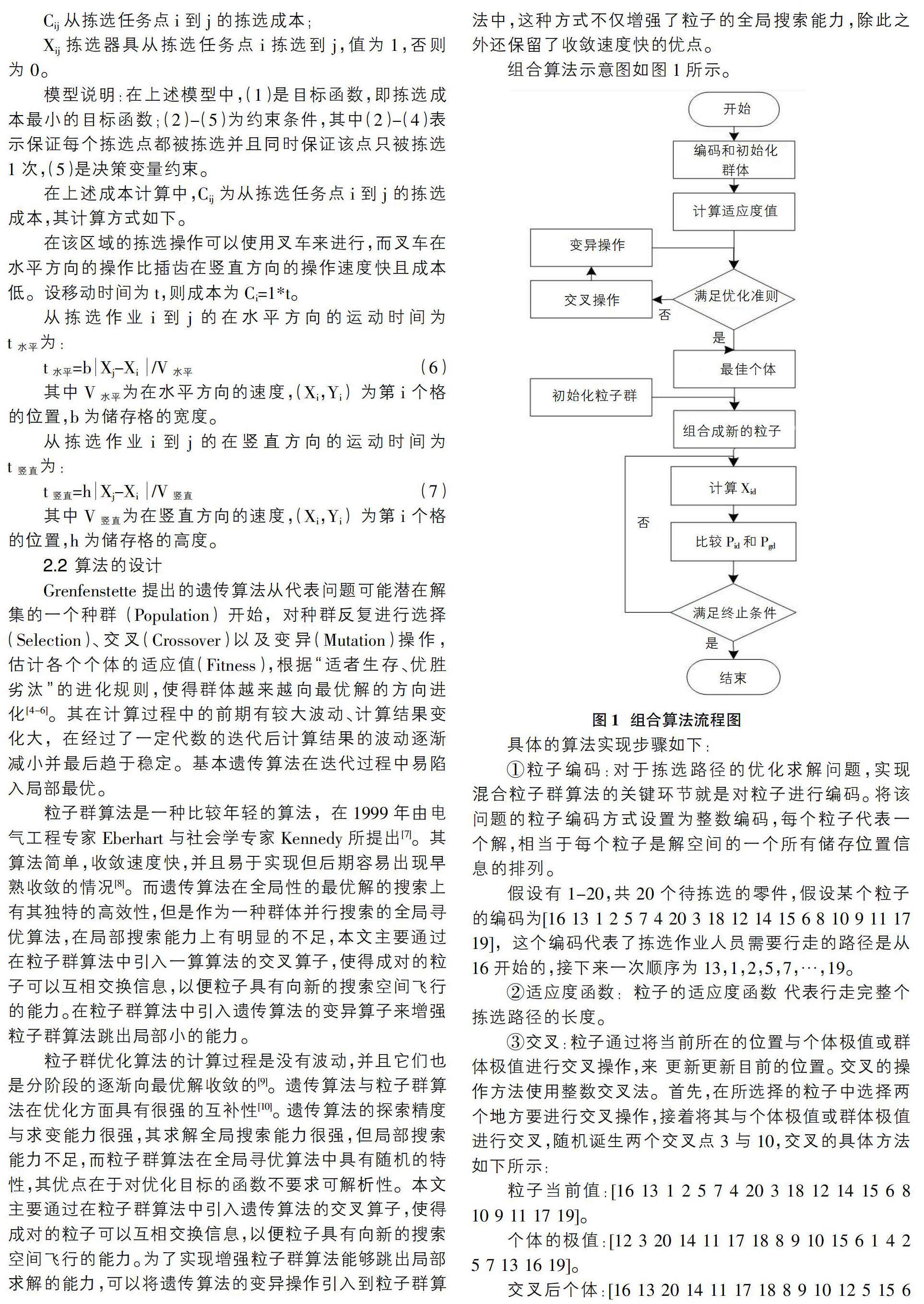

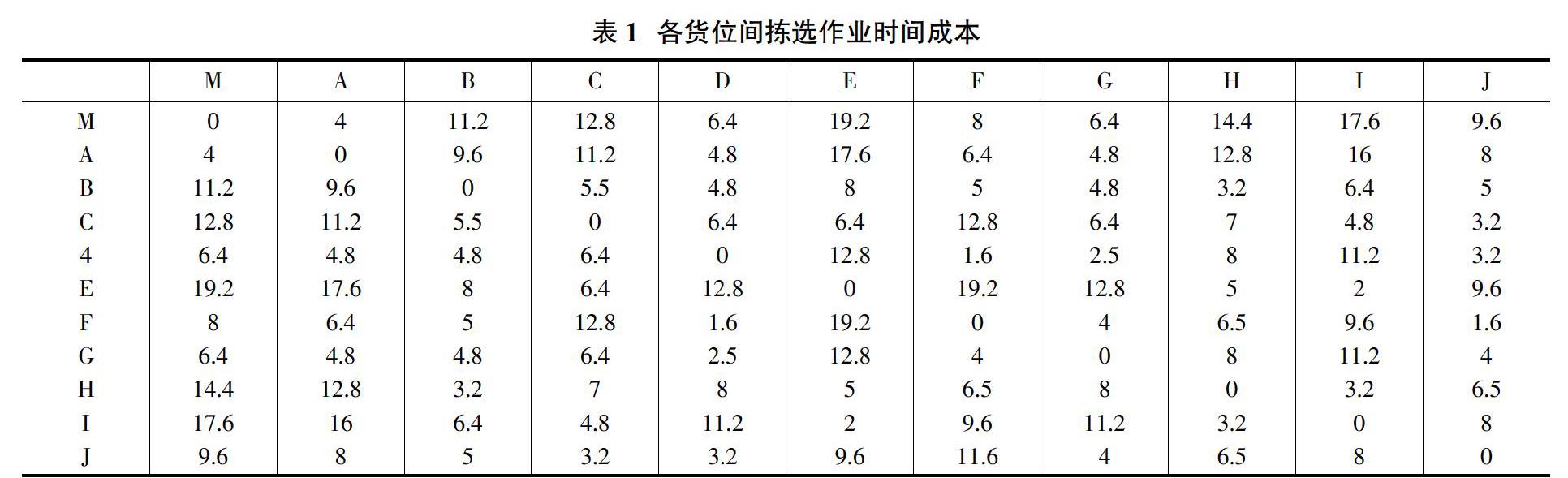

摘要:影響物流時效的核心環(huán)節(jié)是揀選作業(yè),其對物流成本及競爭力都有著非常重要的影響作用。目前,我國多數(shù)的物流企業(yè)均是人工分揀。但是隨著分揀量的增加、分送點的增多,配貨響應(yīng)時間的縮短和服務(wù)質(zhì)量的提高,單憑人工分揀必將無法滿足大規(guī)模揀貨的要求。針對車間內(nèi)既需要排序同時又需要揀選的操作來說,存在著人員行走距離較長,路線交叉,揀錯零件的風(fēng)險高等問題。分析后對此問題提出了利用使用燈光揀選與多層貨架結(jié)合的方式替代現(xiàn)有的揀選方式,構(gòu)建數(shù)學(xué)模型,并通過遺傳和粒子群的混合算法對其進行求解,進而對揀選的路徑進行優(yōu)化,最終設(shè)計出成本最低的揀選方案。?

Abstract: As the core link that affects the effectiveness of logistics, picking operation, which has a very important impact on logistics cost and competitiveness. At present, most of the logistics enterprises in China are manual sorting. However, with the increase of sorting volume, distribution points, distribution response time and service quality, manual sorting alone will not meet the requirements of large-scale picking. For the operation of sorting and picking in the workshop, there are many problems, such as long walking distance, cross route and high risk of picking wrong parts. After analysis, this paper proposes to use the combination of light picking and multi-layer shelf to replace the existing way of picking, build a mathematical model, and solve it through the hybrid algorithm of genetic and particle swarm optimization, then optimize the path of picking, and finally design the lowest cost picking scheme.

關(guān)鍵詞:排序區(qū);燈光揀選;遺傳算法;粒子群算法;揀選路徑

Key words: sorting area;PTL;GA;PSO;Picking Path

中圖分類號:TP18 ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?文獻標(biāo)識碼:A ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?文章編號:1006-4311(2020)19-0249-05

0 ?引言

作為影響物流時效的核心環(huán)節(jié),揀選作業(yè)對物流成本和競爭力有著至關(guān)重要的影響作用[1]。在物流領(lǐng)域內(nèi),揀選是指揀選式配貨作業(yè),是揀選人員或揀選工具在各個儲存點內(nèi)行走并將待揀選的貨物取出,完成揀選任務(wù)的相對運動[2]。作倉儲運營系統(tǒng)中的重要環(huán)節(jié),揀選技術(shù)的發(fā)展日新月異,從傳統(tǒng)的揀選人員手持揀貨單揀貨到使用PDA掃描揀貨,從射頻識別技術(shù)到電子標(biāo)簽輔助揀選技術(shù),從貨到人系統(tǒng)到機器人自動揀貨技術(shù),琳瑯滿目。企業(yè)在設(shè)計倉儲運營系統(tǒng)時,面臨越來越多的選擇。

一般需要物流揀選操作的車間,進行的都是揀選作業(yè)。……