持續質量改進模式在檢驗科設備管理中的應用價值

劉大博 蘇姝 王宇

[摘要] 目的 探究持續質量改進模式在檢驗科設備管理工作中的應用價值。方法 選取2018年1月—2019年1月間對該院檢驗科人員共32名和132例患者列為觀察組(持續質量改進模式),同期另抽取32名檢驗人員及132例患者作為參照組(常規管理模式),觀察兩組檢驗科人員管理后考核評分、設備管理效果及患者滿意度情況。結果 觀察組檢驗科人員管理后理論知識、操作技能、服務質量、設備保養與維護、設備使用流程和設備管理能力評分情況均與參照組比較,差異有統計學意義(P<0.05);觀察組檢驗科人員管理后設備放置規范率、設備正確使用率、設備故障發生率均為3.12%,顯著低于參照組設備放置規范率15.63%、設備正確使用率12.50%、設備故障發生率18.75%,差異有統計學意義(P<0.05);觀察組患者對檢驗科人員工作滿意度為98.48%,顯著高于參照組患者對檢驗科人員工作滿意度87.88%,差異有統計學意義(P<0.05)。結論 針對檢驗科設備管理工作中實施持續質量改進模式,具有較高的應用價值,可作為一種理想的管理辦法。

[關鍵詞] 持續質量改進模式;檢驗科;設備;管理;價值

[中圖分類號] R392 [文獻標識碼] A [文章編號] 1672-5654(2020)02(b)-0062-03

[Abstract] Objective To explore the application value of continuous quality improvement model in equipment management of inspection department. Methods A total of 32 patients and 132 patients in the laboratory of the hospital between January 2018 and January 2019 were selected as the observation group (continuous quality improvement model), and another 32 patients and 132 patients were selected as the observation group during the same period. The reference group (conventional management mode), observed the evaluation scores, equipment management effects, and patient satisfaction of the laboratory staff in the two groups. Results The theoretical knowledge, operation skills, service quality, equipment maintenance and maintenance, equipment use process and equipment management ability scores of the observation group staff in the observation group were compared with the reference group, the difference was statistically significant(P<0.05); the observation group inspection After the staff management, the equipment placement specification rate, equipment correct usage rate, and equipment failure occurrence rate were all 3.12%, which were significantly lower than the reference group equipment placement specification rate of 15.63%, and the equipment correct use rate of 12.50%, the equipment failure rate was 18.75%, the difference was statistically significant(P<0.05); the observation group's work satisfaction with the laboratory staff was 98.48%, which was significantly higher than the reference group's work satisfaction with the laboratory staff 87.88%, the difference was statistically significant(P<0.05). Conclusion The implementation of continuous quality improvement mode in the management of laboratory equipment has high application value and can be used as an ideal management method.

[Key words] Continuous quality improvement model; Inspection department; Equipment; Management; Value

檢驗儀器設備在醫療服務中是一種極為重要的硬件設施,檢驗結果是否真實、準確可直接影響到患者的切身利益,甚至關系到醫院的口碑和權威性。而檢驗儀器設備管理是反映出檢驗科管理水平的好壞,更是檢驗水平高低及檢驗質量的首要條件。若在儀器設備管理中出現設備操作不規范、保養或維護不到位及管理制度不完善等問題,不僅對檢驗質量造成一定影響,同時無法確保向醫生提供可靠檢測報告作為診斷依據。因此,為尋求一種安全、可靠的設備管理方案,已成為醫院檢驗科需要面臨解決的首要問題[1]。該文對該院檢驗科設備采取持續質量改進模式后的應用價值進行深入探究,報道如下。

1? 資料與方法

1.1? 一般資料

回顧分析該院檢驗科人員(n=32)、患者(n=132)為觀察組,在此期間,另外選取檢驗科人員(n=32)、患者(n=132)為參照組,其中觀察組男性患者72例,女性患者60例;年齡20~76歲,平均年齡(40.63±2.25)歲;檢驗人員年齡28~36歲,平均年齡(29.62±2.38)歲;職稱:主任技師1名、副主任技師1名、主管技師8名、技師22名;學歷:研究生7名、本科25名。參照組男性患者68例,女性患者64例;年齡23~73歲,平均年齡(45.58±2.45)歲;年齡23~75歲,平均年齡(47.62±1.38)歲;檢驗人員年齡26~38歲,平均年齡(34.58±2.47)歲;職稱:主任技師1名、副主任技師1名、主管技師7名、技師23名;學歷:研究生6名、本科26名。各組資料進行比對,差異無統計學意義(P>0.05)。

1.2? 分組及管理方法

參照組:采用常規管理模式,觀察組采用持續質量改進模式,具體內容如下:①建立設備管理小組,派科室專業人員依據院內《檢驗科規章制度》及《檢驗科管理制度》對檢驗科人員及設備進行監督、管理。定期開展有關操作技能、業務設備維修與保養的相關知識制成合理方案。②依據該院檢驗科設備管理中的實際情況,遵照國家相關規定下給予對應的設備管理方法,并記錄好一起設備的購買及操作管理工作。同時,對檢驗人員的工作職責給予明確要求,做到工作有章可循。構建負責人責任制度,對儀器設備的使用及擺放應嚴格遵照規定進行操作,并認真填寫管理記錄。通過完善管理制度,有效提升檢驗人員的職業心與責任心,進而延長了儀器設備的使用壽命,保證了檢驗工作的安全性及穩定性[2]。③加強檢驗人員質量控制工作整體水平,定時開展培訓工作,通過理論實踐中提高自身業務水平。此外,邀請能力較強人員定期參與外出進修培訓學習,通過各種各樣形式中幫助檢驗人員對于新設備、新技術以及銷售企業等方面的認知水平不斷提高,最終培養出組織能力強、工作經驗豐富以及責任感強的檢工作團隊。④遵照設備保養說明書進行日常維修及保養,工作環境的好壞會直接影響設備的性能與使用壽命。對于長時間不使用的設備需定期開機,做好防塵、防潮工作;對于存放區域應避開帶有酸堿等腐蝕性氣體及液體;對于設備的管理系統應采用乙醇及乙醚混合液進行擦拭[3]。

1.3? 觀察指標

統計兩組檢驗科人員管理后(理論知識、操作技能、服務質量、設備保養與維護、設備使用流程、設備管理能力)考核評分及設備管理效果(設備放置規范率、設備正確使用率、設備故障發生率;觀察及比對兩組患者對檢驗科人員工作滿意度情況。

1.4? 療效判定

采用調查問卷形式對兩組檢驗科人員考核成績進行評分,包括理論知識、操作技能、服務質量、設備保養與維護、設備使用流程、設備管理能力6個方面內容,各項總分為0~100分,得分越高,則代表檢驗科人員考核成績越好;患者滿意度是通過非常滿意、一般、不滿意3個維度,并以百分制作為評分標準,分數越高,則說明患者對檢驗科人員工作滿意度越高[4]。滿意度=(非常滿意例數+一般例數)/總例數×100.00%。

1.5? 統計方法

應用SPSS 24.0統計學軟件進行數據分析,計量資料用(±s)表示,組間比較行t檢驗,計數資料用[n(%)]表示,組間比較行χ2檢驗,P<0.05為差異有統計學意義。

2? 結果

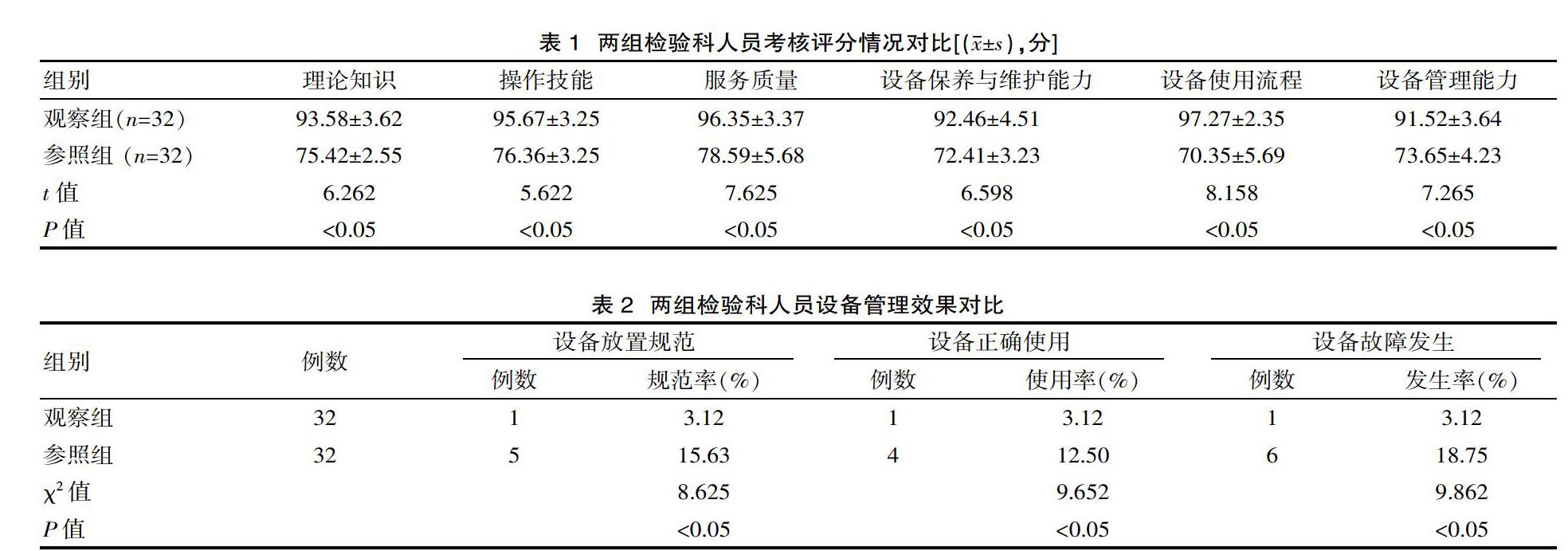

2.1? 比較兩組檢驗科人員管理后綜合考核評分情況

綜合考核評分情況見表1。

2.2? 比較兩組檢驗科人員管理后設備管理情況

設備管理情況見表2。

2.3? 比較兩組患者對檢驗科人員工作滿意度情況

對檢驗科人員工作滿意度情況見表3。

3? 討論

檢驗科設備管理因過去管理處于局限性,受到某種傳統因素的影響下,促使檢驗科實際過程中,檢驗科人員的工作狀態持續處于被動狀態。加上醫院更注重檢驗結果的精準性,對于現存的問題未能夠給予及時的總結與改進,最終導致同種錯誤頻頻出現,無法達到預期效果。該文通過對該院檢驗科設備及人員設立小組、定期培訓與進修學習有關業務水平及操作技能等內容,從中調動檢驗人員對檢驗工作的積極性,增加對工作的認同,由被動變為主動,迅速適應有關制度及管理措施要求,從未提升自身技能。此外,通過定期加強對儀器設備的維修與保養,真正做到將有效策略落到實處,最終實現醫院工作持續穩定的提升。

該次研究證實了觀察組理論知識、操作技能、服務質量、設備保養與維護、設備使用流程和設備管理能力評分情況,均優于參照組(P<0.05);觀察組設備放置規律規范、設備使用、設備故障各發生1例,占總發生率的3.12%,參照組設備放置規律規范、設備使用、設備故障分別發生5例、4例、6例,分別占總發生率的15.63%、12.50%、18.75%,觀察組優于參照組(P<0.05);觀察組滿意度98.48%,參照組滿意度87.88%,觀察組高于參照組(P<0.05);這與李頻等[5]在研究報告中的結果基本吻合。

綜上所述,選擇持續質量改進模式符合當前醫療改革的要求,具有較為廣闊的發展前景,能夠進一步為眾多醫院檢驗科設備管理中提供一份力量。

[參考文獻]

[1]? 王猛,趙凌燕,林甜甜,等.基于信息化系統的持續質量改進在血標本質量控制中的應用[J].齊魯護理雜志,2018,24(13):124-125.

[2]? 黃晨韻.檢驗科質量管理中持續質量改進的應用價值[J].中醫藥管理雜志,2018,26(18):141-143.

[3]? 吳玲燕.持續質量改進在基層醫院檢驗質量管理中的實踐[J].中醫藥管理雜志,2018,26(17):120-122.

[4]? 劉華.醫院檢驗科檢驗設備的質量控制[J].醫療裝備,2018, 31(11):54-55.

[5]? 李頻,曾碧新.新形勢下持續質量改進在檢驗科設備管理中的應用效果[J].數理醫藥學雜志,2017,30(9):1416-1418.

(收稿日期:2019-11-12)